Lifting rib of clothes disposal facility and clothes disposal facility

A technology for clothes processing equipment and lifting ribs, which can be applied to other washing machines, textiles and papermaking, household appliances, etc., and can solve the problems that cannot be disassembled by itself and affect the washing and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

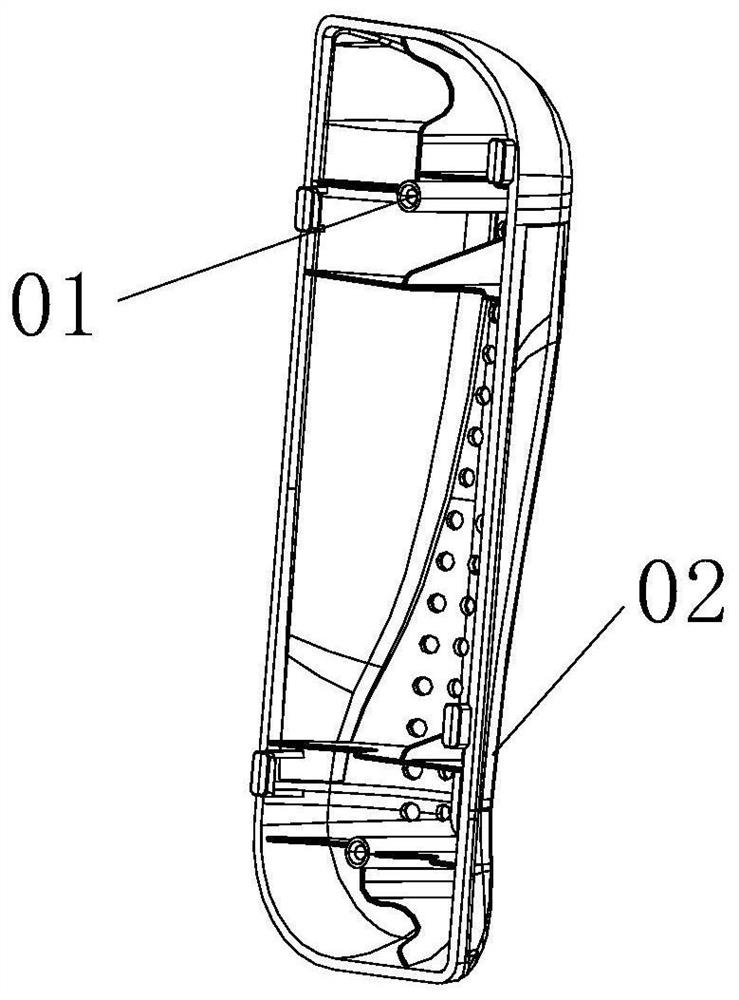

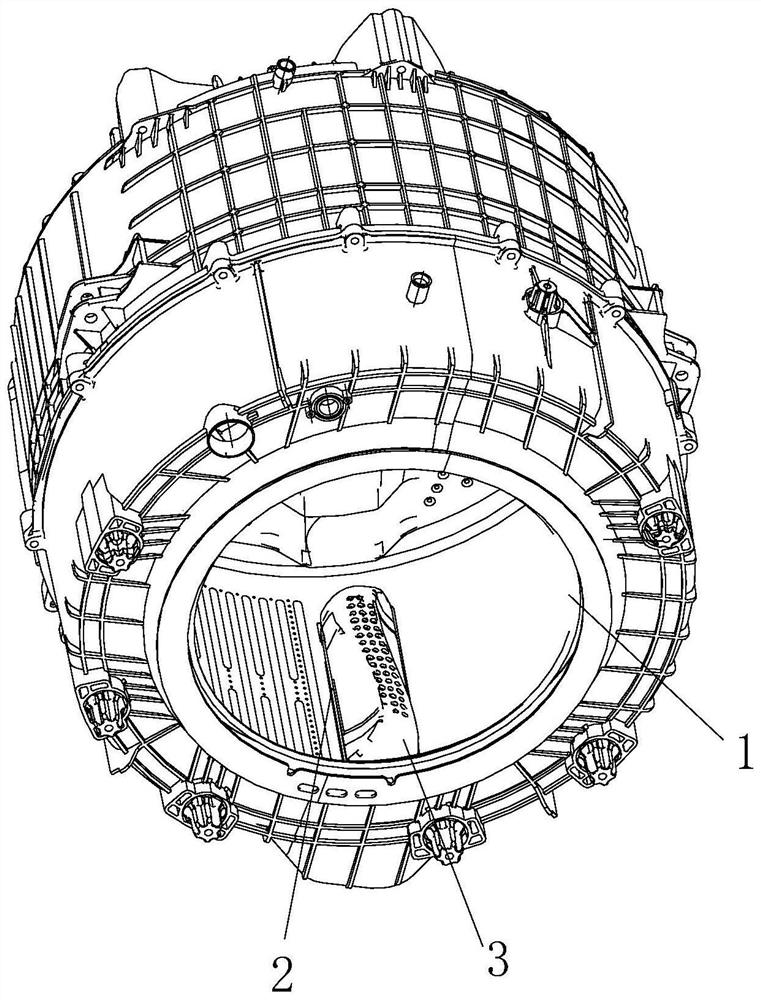

[0051] Such as Figure 1-7 As shown, in this embodiment, the installation base 2 of the lifting rib is fixed on the side wall of the inner tube 1 , and the lifting rib main body 3 is detachably fixed on the installation base 2 .

[0052] When installing and fixing the lifting ribs on the inner wall of the inner cylinder 1, first install the installation base 2 on the inner wall of the inner cylinder 1. In order to facilitate installation and positioning, the installation base 2 and the inner wall of the inner cylinder 1 There are positioning structures that cooperate with each other, and the installation base 2 is positioned on the inner wall of the inner cylinder 1 through the positioning structures. In this way, the installation can be performed conveniently, quickly and accurately, the position of the installation base 2 can be prevented from shifting, the situation of needing to waste time for adjustment can be avoided, and the installation efficiency can be improved.

[...

Embodiment 2

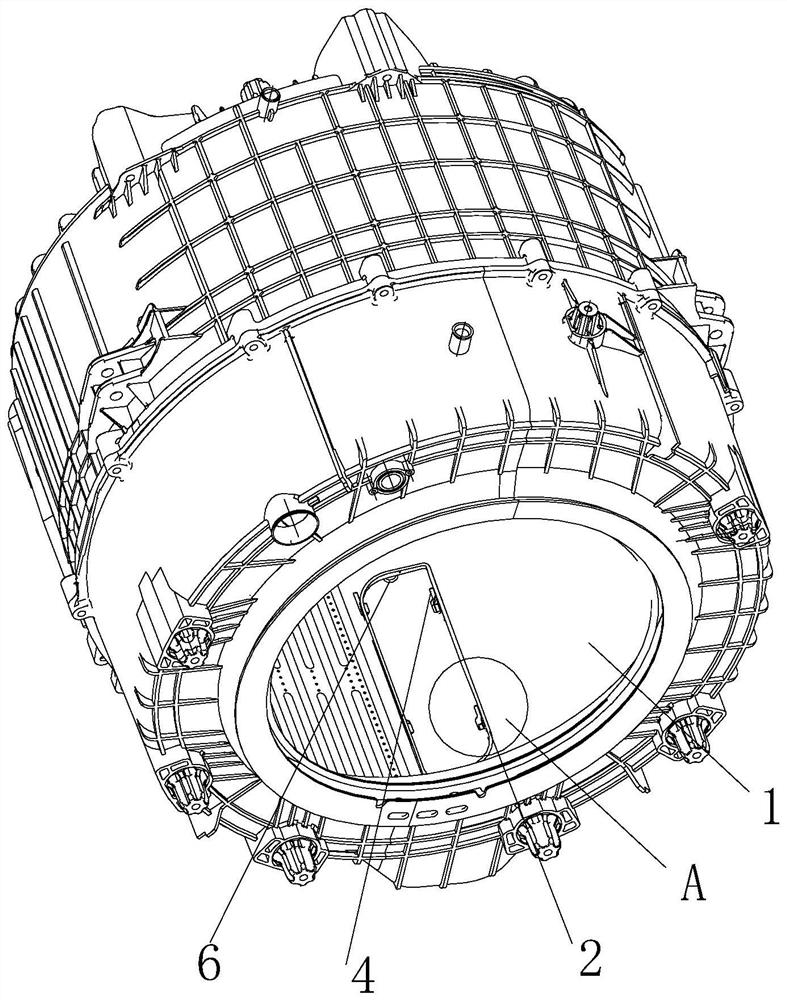

[0067] Such as Figure 8 As shown, this embodiment is a further limitation of Embodiment 1. In this embodiment, the lifting rib includes a separate installation base 2 and a lifting rib main body 3, and the installation base 2 is fixed on the inner cylinder 1. On the side wall, the lifting rib main body 3 is detachably fixed on the installation base 2 . The inside of the lifting rib main body 3 has an accommodating chamber 10 for placing the laundry treatment reagent 11, the accommodating chamber 10 has a through hole communicating with the inner cylinder 1, and the laundry treatment reagent 11 is released into the inner cylinder 1. , or the air and / or liquid inside the inner barrel 1 enters the accommodating chamber 10 .

[0068] The laundry treatment reagent 11 is added in the accommodating chamber 10. During the laundry treatment process, the laundry treatment reagent can treat the incoming air or washing water in the accommodating chamber 10, or the air and / or liquid in t...

Embodiment 3

[0076] This embodiment is a further limitation of Embodiment 1. In this embodiment, the lifting rib includes a separate installation base 2 and a lifting rib main body 3, and the installation base 2 is fixed on the side wall of the inner cylinder 1. , the lifting rib main body 3 is detachably fixed on the installation base 2 . The lifting rib main body 3 is also provided with a lint filtering structure for filtering lint, and the lifting rib can be used as a lint filter.

[0077] As a specific implementation, the main body 3 of the lifting rib is provided with a water inlet and a water outlet, and a filter is provided at the water inlet or the water outlet.

[0078] In this solution, the filter screen can be a mesh bag, and when the filter mesh bag is arranged at the water inlet, it can be hidden in the inner cavity of the lifting rib main body 3 . When the water in the inner tube 1 enters the water inlet and flows out from the water outlet, the lint in the washing water is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com