High-density and high-barrier polyethylene plastic thin film and making method thereof

A technology of plastic film and production method, which is applied in the direction of chemical instruments and methods, flexible coverings, types of packaging items, etc., and can solve the problem of affecting the use effect of polyethylene plastic film, low density of polyethylene plastic film, and no adsorption function, etc. problem, achieve good barrier effect, strong barrier effect, and improve barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

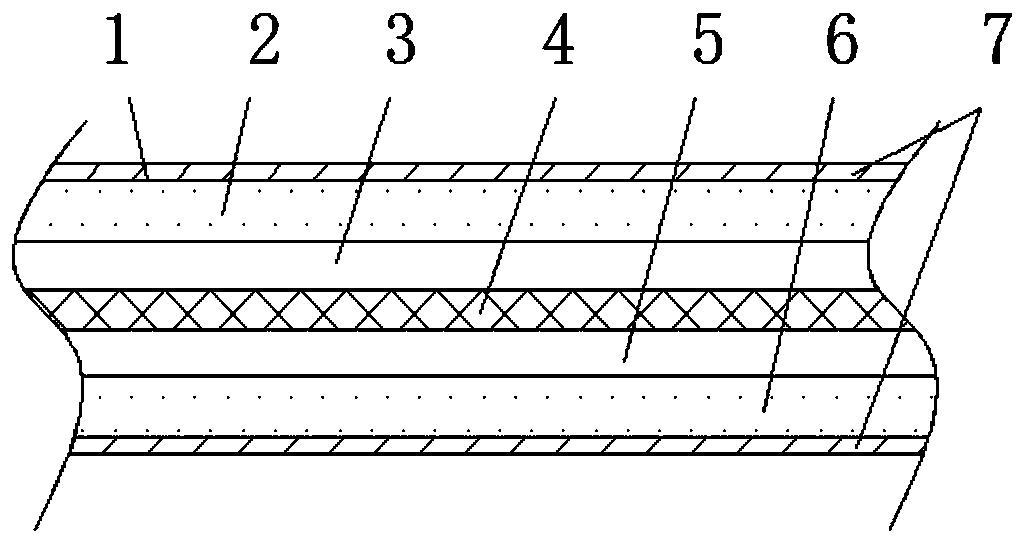

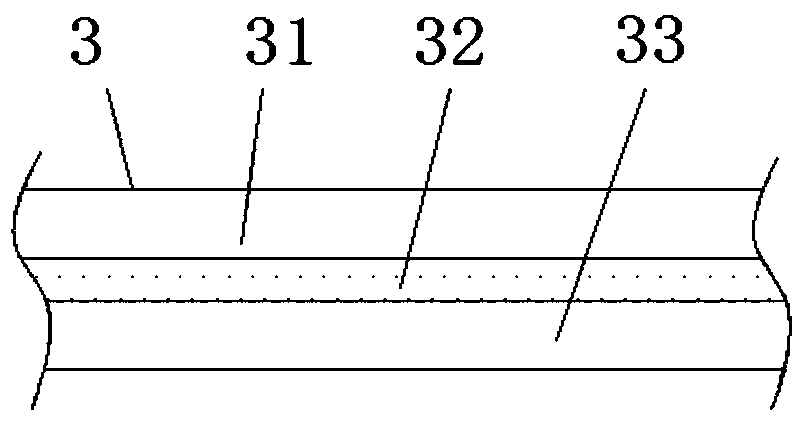

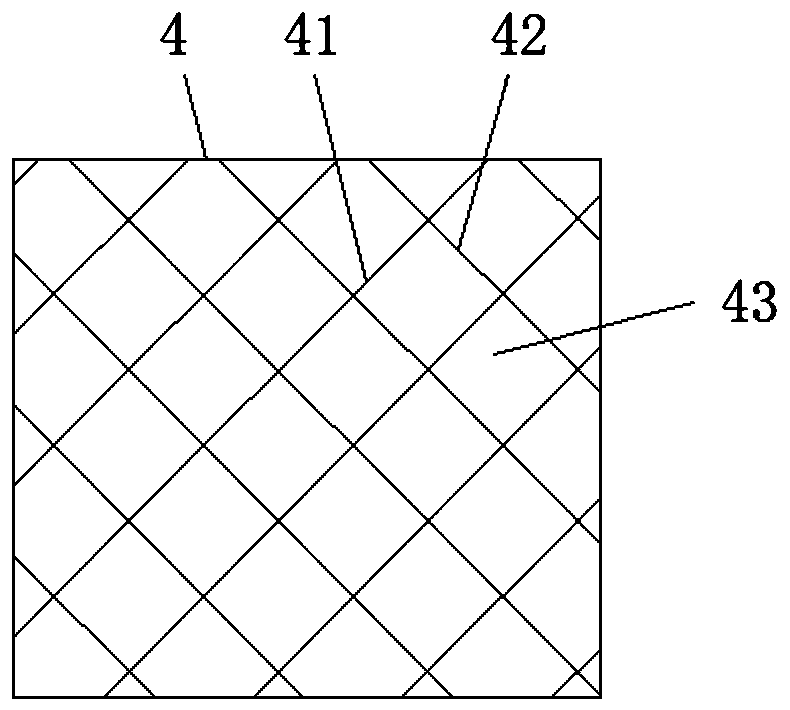

[0024] This embodiment 1 provides a kind of high-density high-barrier polyethylene plastic film, please refer to Figure 1-3 , the present invention provides a technical solution: a high-density high-barrier polyethylene plastic film, comprising a film body 1, an upper film layer 2, a first thickening layer 3, a first layer body 31, an adsorption layer 32, a second layer Body 33, reinforcement layer 4, warp thread 41, weft thread 42, grid 43, second thickening layer 5, lower film layer 6 and waterproof layer 7, upper film layer 2 is arranged on the top of film body 1, and upper film layer 2 The bottom of the first thickened layer 3 is connected with the first thickened layer 3, and the reinforced layer 4 is fixed on the first thickened layer 3, the second thickened layer 5 is connected with the bottom of the reinforced layer 4, and the bottom of the second thickened layer 5 is provided with The lower film layer 6, the surface of the upper film layer 2 and the lower film layer ...

Embodiment 2

[0028] This embodiment 2 provides a kind of manufacture method of high-density high-barrier polyethylene plastic film, please refer to figure 1 , the above method will be described in detail below.

[0029] A method for making a high-density high-barrier polyethylene plastic film, comprising the following steps:

[0030] 1. Put the reinforcement layer 4 on the gluing machine, apply adhesive on its surface, and then distribute and bond the first thickening layer 3 and the second thickening layer 5 on both sides of the reinforcement layer 4;

[0031] 2. Then use the leveling device to level the reinforcement layer 4, the first thickened layer 3 and the second thickened layer 5, then use the scraping device to scrape off the excess adhesive, and then use the drying device to consolidate Layer 4, the first thickened layer 3 and the second thickened layer 5 are sticky and then dried;

[0032] 3. The upper film layer 2, the lower film layer 6 and the reinforcement layer 4, the fir...

Embodiment 3

[0036] This embodiment 3 provides another method for making a high-density high-barrier polyethylene plastic film, please refer to figure 1 , the above method will be described in detail below.

[0037] A method for making a high-density high-barrier polyethylene plastic film, comprising the following steps:

[0038] 1. Put the reinforcement layer 4 on the gluing machine, apply adhesive on its surface, and then distribute and bond the first thickening layer 3 and the second thickening layer 5 on both sides of the reinforcement layer 4;

[0039] 2. Then use the leveling device to level the reinforcement layer 4, the first thickened layer 3 and the second thickened layer 5, then use the scraping device to scrape off the excess adhesive, and then use the drying device to consolidate Layer 4, the first thickened layer 3 and the second thickened layer 5 are sticky and then dried;

[0040] 3. The upper film layer 2, the lower film layer 6 and the reinforcement layer 4, the first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com