Coating material having health functions and specially used for leather

A technology for coating materials and leather, applied in the field of materials, can solve problems such as no additional functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

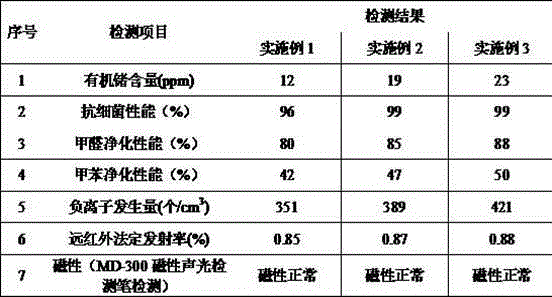

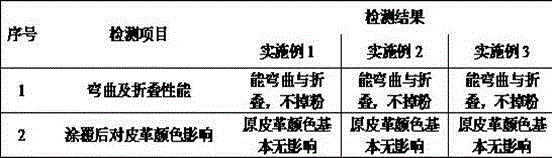

Embodiment 1

[0023] The weight percentage formula of the leather front coating material: 2 parts of colorless transparent nano-silver solution, 2 parts of water-soluble far-infrared dispersion liquid, 3 parts of organic germanium aqueous solution, 35 parts of PU transparent varnish, and 58 parts of deionized water.

[0024] The weight percentage formula of the coating material on the back of the leather: 5 parts of activated carbon powder, 10 parts of magnetic powder, 0.5 part of organic bentonite, 2 parts of silver-loaded zirconium phosphate powder, 2 parts of nano-zinc oxide, 1 part of hydroxyethyl cellulose ether, 0.2 part of tourmaline powder , 0.5 parts of 5040 type dispersant, 0.1 parts of AGITAN-208 type defoamer, 10 parts of VAE emulsion, 0.5 parts of 2,2,4-trimethyl 1,3-pentanediol monoisobutyrate, Kh-570 0.1 part of type silane coupling agent, 0.2 part of X-405 type wetting agent, 0.5 part of polyacrylate thickener, 0.1 part of Kathon, 0.2 part of BEK-500 type antifungal agent, 67...

Embodiment 2

[0027] The weight percentage formula of the leather front coating material: 3 parts of colorless transparent nano-silver solution, 1 part of water-soluble far-infrared dispersion liquid, 5 parts of organic germanium aqueous solution, 45 parts of PU transparent varnish, and 46 parts of deionized water.

[0028] The weight percentage formula of the coating material on the back of the leather: 8 parts of activated carbon powder, 8 parts of magnetic powder, 1.5 parts of organic bentonite, 1 part of silver-loaded zirconium phosphate powder, 3 parts of nano-zinc oxide, 0.5 part of hydroxyethyl cellulose ether, and 0.3 part of tourmaline powder , 1 part of 5040 type dispersant, 0.2 parts of AGITAN-208 type defoamer, 18 parts of VAE emulsion, 1.2 parts of 2,2,4-trimethyl 1,3-pentanediol monoisobutyrate, Kh-570 0.2 parts of type silane coupling agent, 0.1 part of X-405 type wetting agent, 0.3 parts of polyacrylate thickener, 0.2 parts of Kathon, 0.1 part of BEK-500 type antifungal agent...

Embodiment 3

[0031] The weight percentage formula of the leather front coating material: 5 parts of colorless transparent nano-silver solution, 0.5 part of water-soluble far-infrared dispersion liquid, 6 parts of organic germanium aqueous solution, 50 parts of PU transparent varnish, and 38.5 parts of deionized water.

[0032] The weight percentage formula of the coating material on the back of the leather: 10 parts of activated carbon powder, 5 parts of magnetic powder, 3 parts of organic bentonite, 0.5 part of silver-loaded zirconium phosphate powder, 4 parts of nano-zinc oxide, 0.1 part of hydroxyethyl cellulose ether, 0.4 part of tourmaline powder , 2 parts of 5040 type dispersant, 0.3 parts of AGITAN-208 type defoamer, 25 parts of VAE emulsion, 2 parts of 2,2,4-trimethyl 1,3-pentanediol monoisobutyrate, Kh-570 0.3 parts of type silane coupling agent, 0.05 parts of X-405 type wetting agent, 0.2 parts of polyacrylate thickener, 0.3 parts of Kathon, 0.05 parts of BEK-500 type antifungal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com