Carbon heating headscarf and preparation method thereof

A technology of carbon heating sheets and scarves, which is applied to scarves, scarves, headscarves, etc., can solve the problem of unsustainable warmth retention effect, and achieve the effect of long warmth retention time, rapid heating and heating, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] 1. Fabrication of carbon conductive yarn

[0031] Put the carbon sensitive material with a viscosity of 100-500mpa.s and a solid content of 5-70% in a stainless steel container, stir well and evenly, and use the padding process to process the yarn without impurities, moisture, and non-sizing The strands and blended yarns are immersed in stainless steel containers, soaked, and then passed through rolls to squeeze liquid (rolled liquid rate 70%), and then dried at a temperature of 110-130°C for 90 seconds, and then baked at a temperature of 140-180°C ℃, time 60 ~ 90s. Yarn or ply, blended yarn can be cotton, hemp, or hemp-cotton and cotton-polyester blended yarn, and the yarn count is 7-21s.

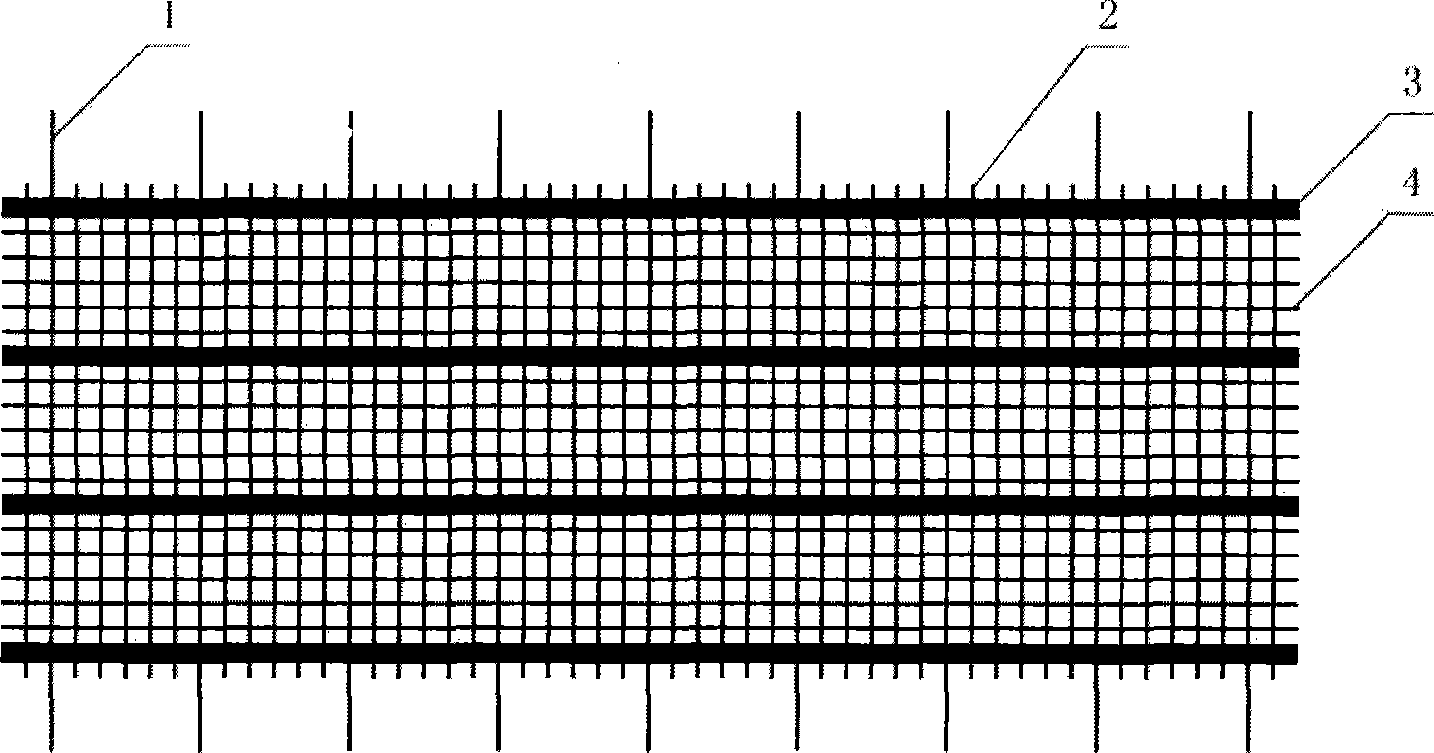

[0032] 2. Fabrication of carbon conductive fabric

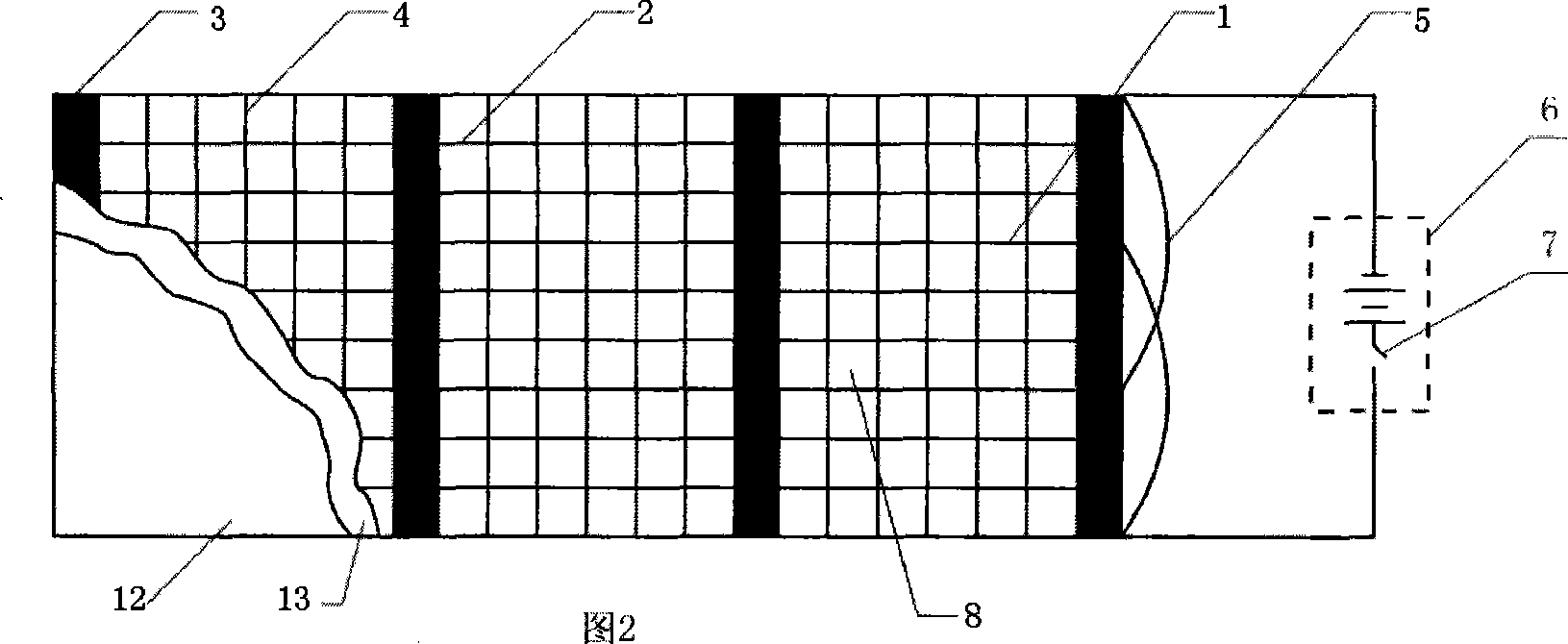

[0033] Such as figure 1 As shown, the weaving method is used to weave a fabric containing conductive filaments 1 and carbon conductive yarns 3 or blended yarns, that is, carbon conductive fabrics. The warp yarns 2 in the fabric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com