Polyene microporous multilayer diaphragm and manufacturing method thereof

A manufacturing method and microporous technology, which are applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of low film breaking temperature, low safety and high safety, and achieve improved safety, The effect of preventing fire and explosion accidents and the simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

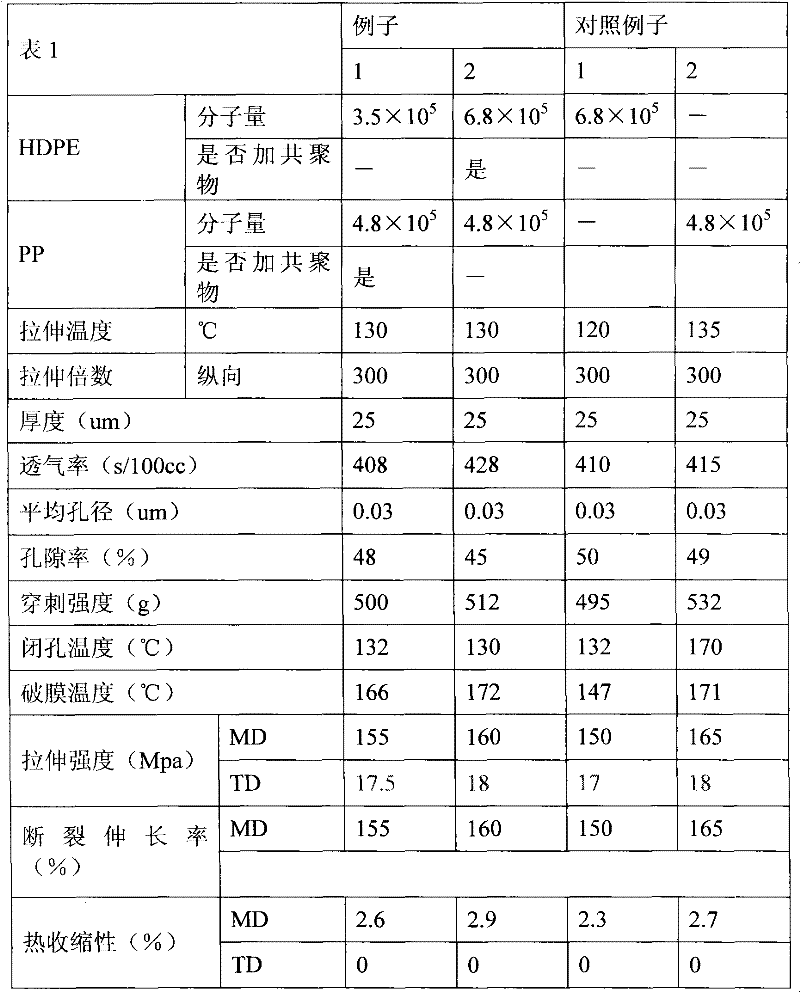

[0034] A polyene microporous multilayer separator, which is composed of three or more polyene layers, at least one layer of the polyene layers is a polyethylene layer, and at least one layer is a polypropylene layer The polyethylene layer and the polypropylene layer are closely attached to each other, and at least one of the adjacent polyethylene and polypropylene layers is a blend containing a certain amount of ethylene-propylene copolymer.

[0035] It is worth mentioning that due to the poor compatibility of polyethylene and polypropylene, the main purpose of adding a certain amount of materials with good compatibility with both polypropylene and polyethylene (such as ethylene-propylene copolymer) is to improve Their compatibility, so the present invention requires that at least one layer in the adjacent polyethylene and polypropylene layers is a material with good compatibility with polypropylene and polyethylene. When two or more polypropylene layers are incorporated into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Closed cell temperature | aaaaa | aaaaa |

| Membrane rupture temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com