Phosphorus diffusion method of crystalline silicon solar cell

A solar cell and phosphorus diffusion technology, applied in the field of solar cells, can solve the problems of low open circuit voltage of solar cells, low conversion efficiency of solar cells, and unfavorable collection of photogenerated carriers, so as to avoid high surface concentration and increase segregation effect, the effect of enhancing the effect of oxidation gettering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

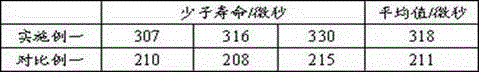

Embodiment 1

[0040] A phosphorus diffusion method for a crystalline silicon solar cell, comprising the steps of:

[0041] (1) Raise the temperature of the diffusion furnace to 760°C, and the maximum nitrogen flow rate is 10000~40000 sccm; enter the boat;

[0042] (2) Adjust the temperature to 780~800°C, the maximum nitrogen flow rate is 10000~20000 sccm, and feed nitrogen and dry oxygen carrying phosphorus source to form a phosphorus-containing silicon dioxide layer; the thickness of the phosphorus-containing silicon dioxide layer is 80nm;

[0043] The flow of the phosphorus-carrying source nitrogen is 100 to 500 sccm, and the flow of dry oxygen is 500 to 1000 sccm;

[0044] The pressure in the furnace is controlled at 100 Pa; the temperature adjustment time is controlled at 500~800 seconds;

[0045] (3) Keep the above-mentioned temperature, pressure, dry oxygen and large nitrogen flow constant, increase the nitrogen gas carrying phosphorus source, and carry out low-temperature diffusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com