Patents

Literature

54results about How to "Reduce phosphorus concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

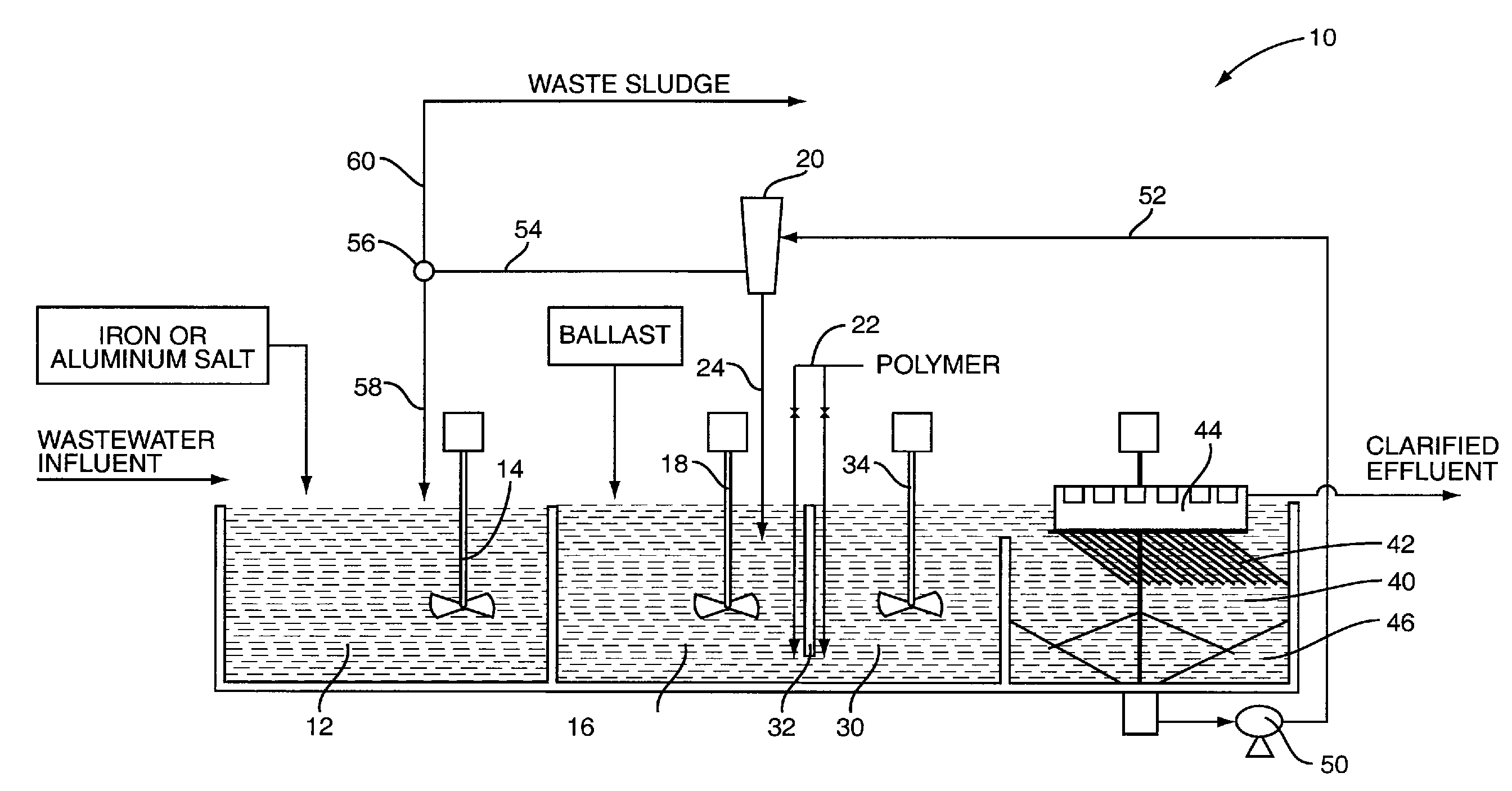

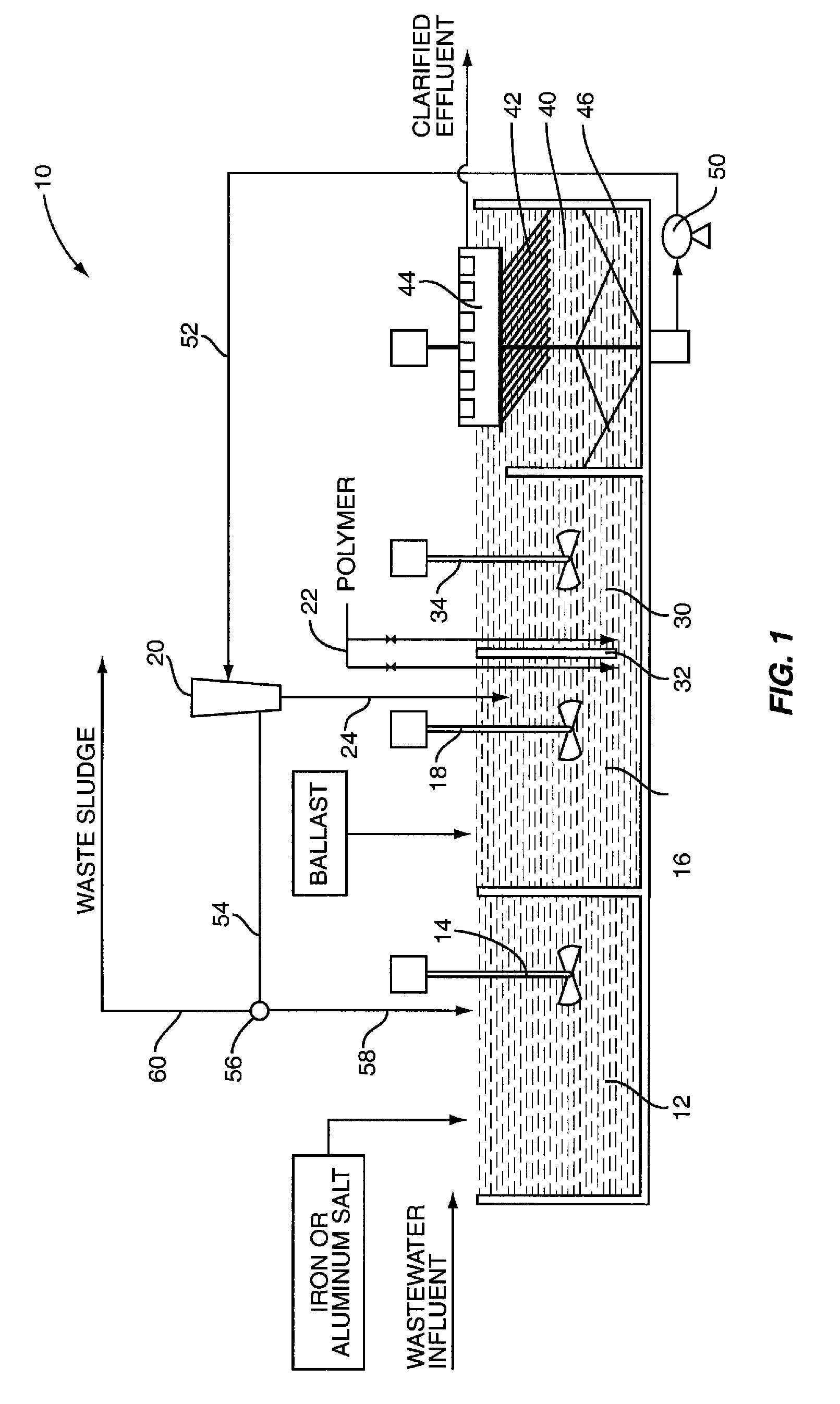

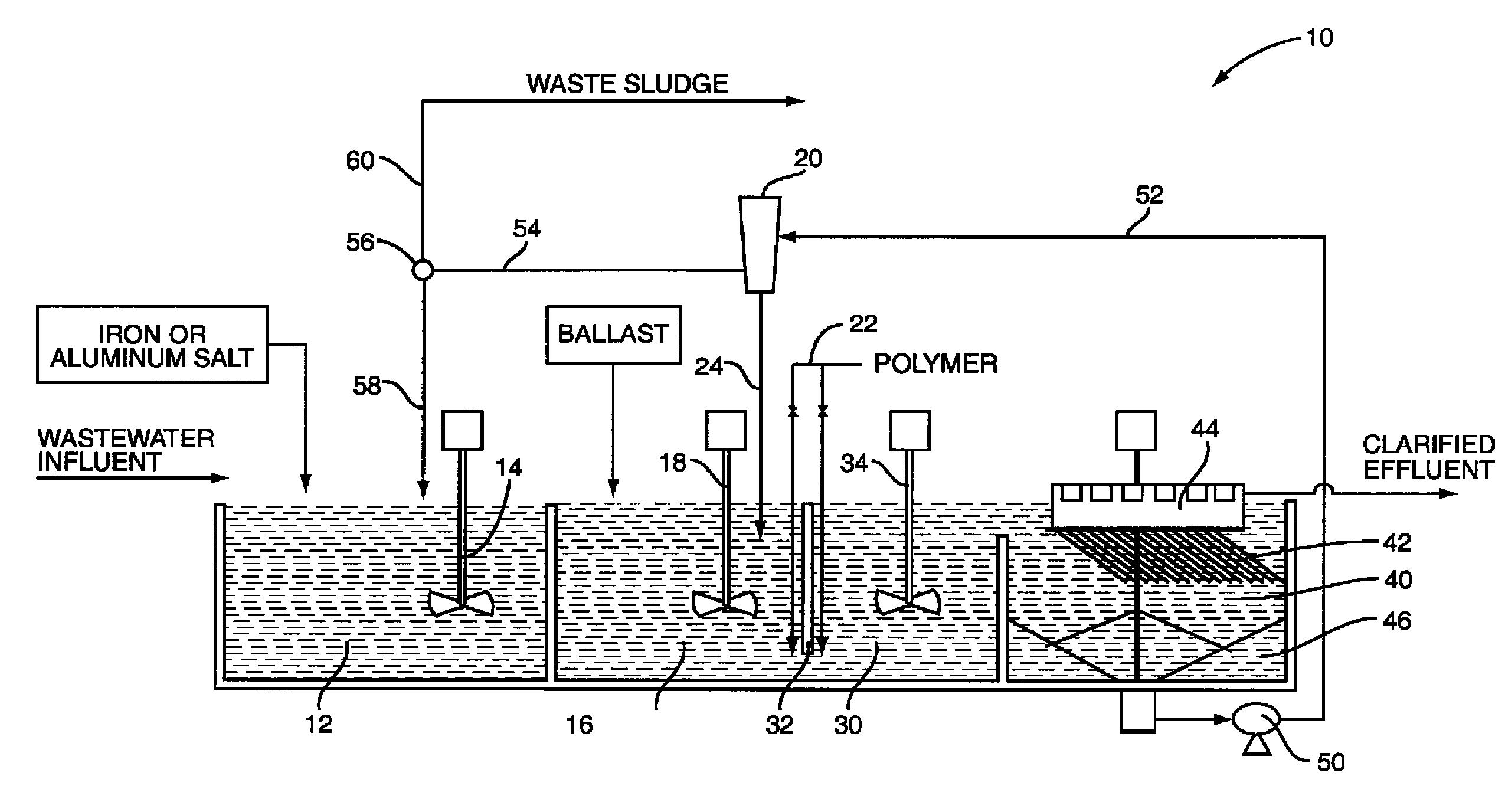

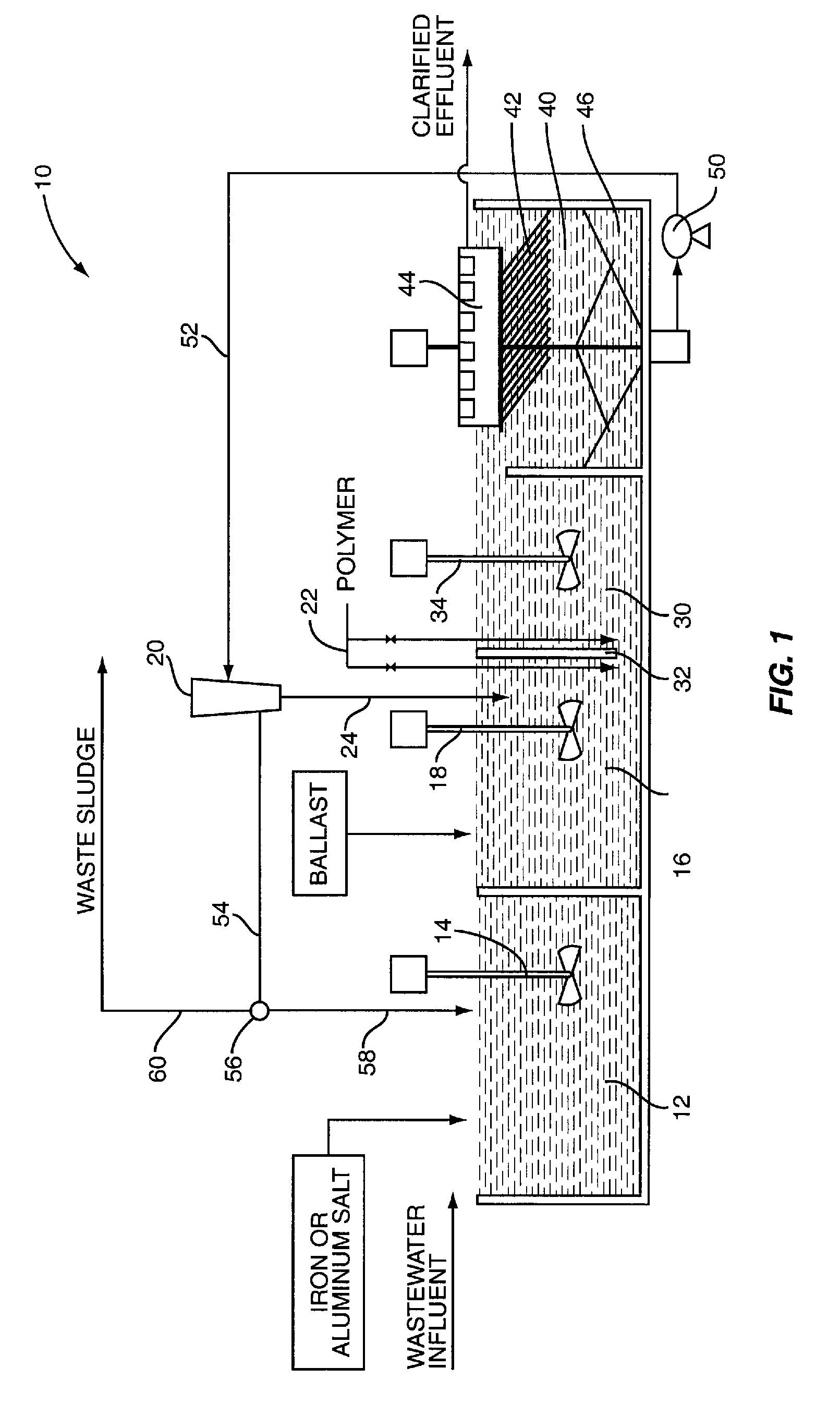

Method of Removing Phosphorus from Wastewater

ActiveUS20080314830A1Increase of concentration of ironReduction of phosphorus concentrationSolid sorbent liquid separationSedimentation separationChemistryAluminium

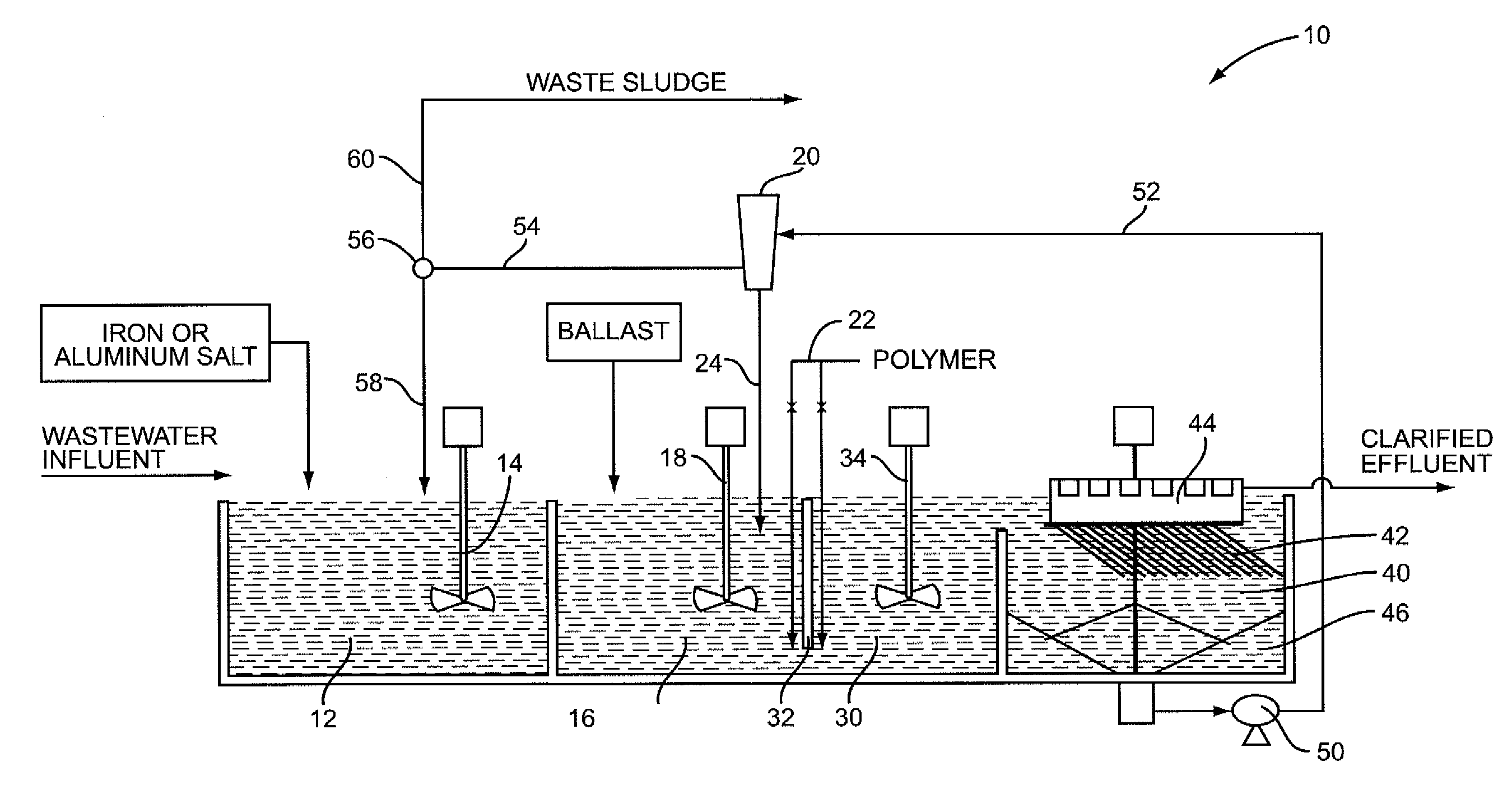

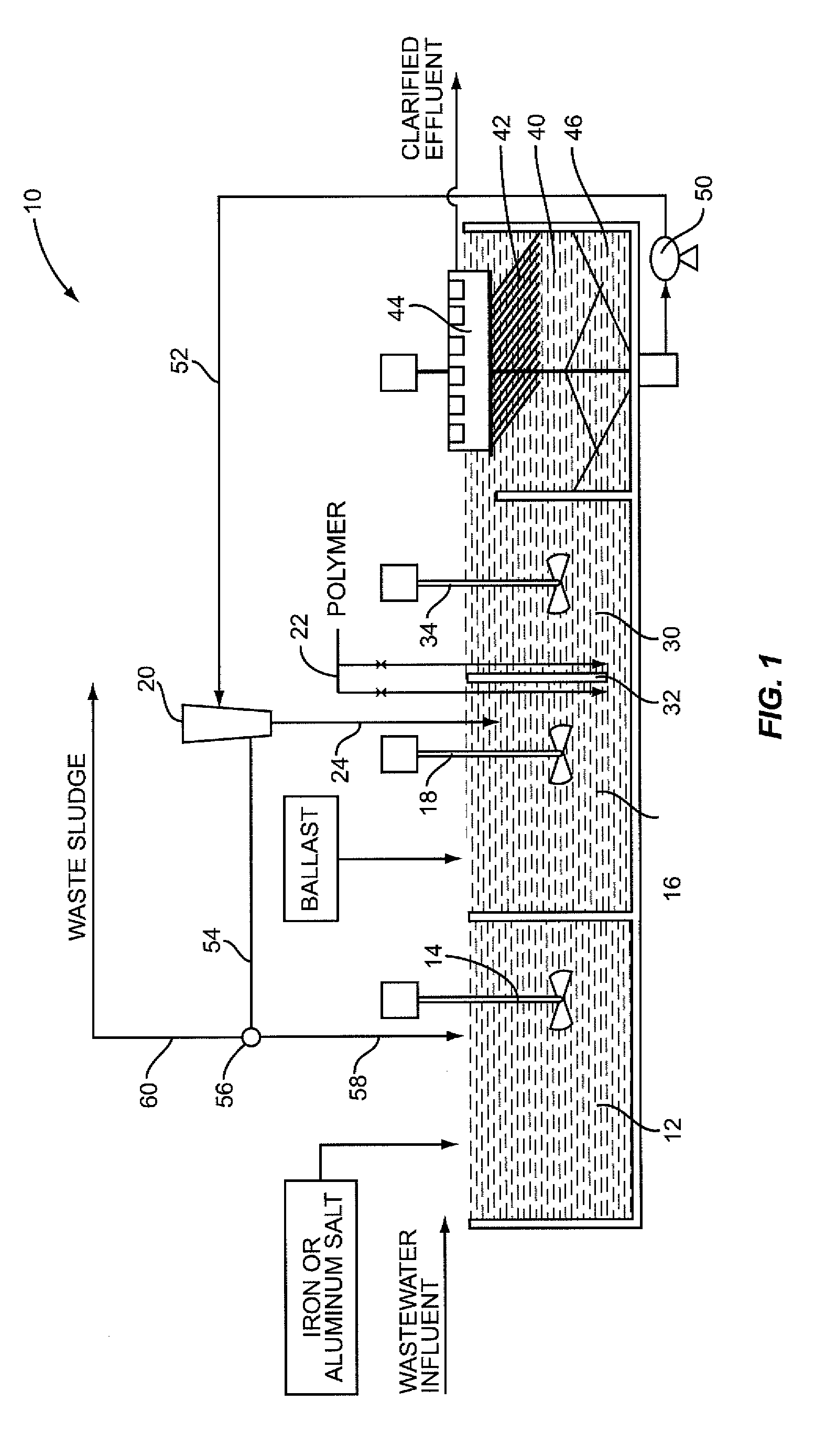

A process for removing phosphorus from wastewater wherein an iron or aluminum salt is added to the wastewater. The iron or aluminum salt results in the precipitation of certain iron or aluminum species that include phosphorus adsorption sites. These iron or phosphorus species are settled and become a part of sludge produced in the course of the wastewater treatment process. By recycling substantial portions of the sludge, the concentration of these iron or aluminum species in the wastewater is increased. This increased concentration results in the presence of large quantities of unused phosphorus adsorption sites that attract and adsorb phosphorus, resulting in phosphorus being removed from the wastewater.

Owner:KRUGER I INC

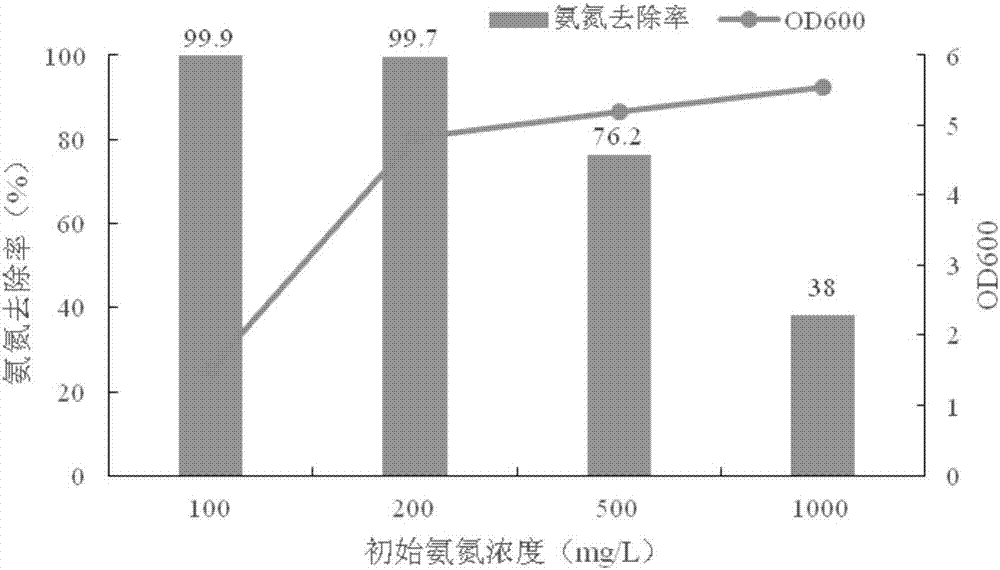

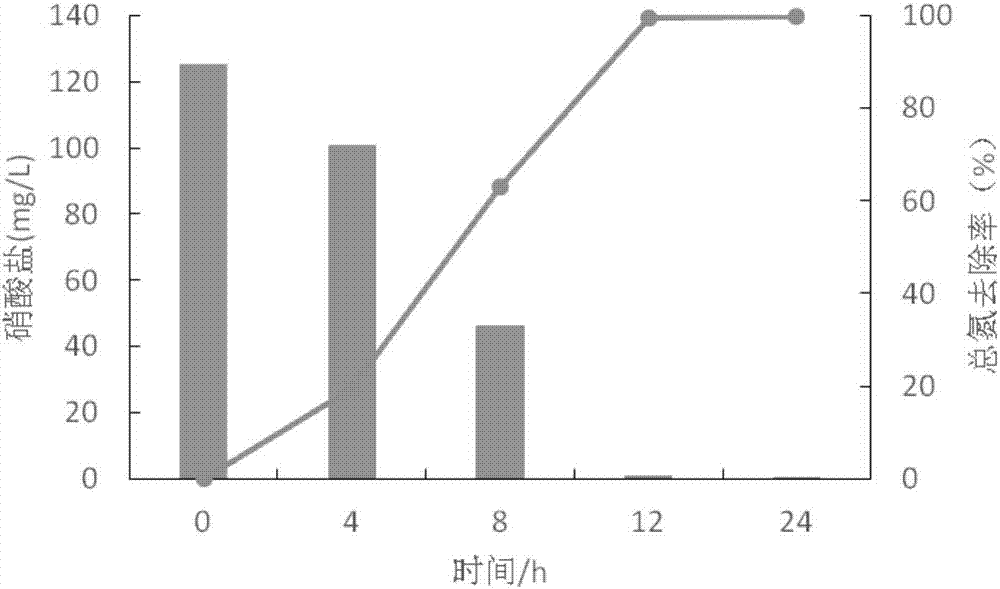

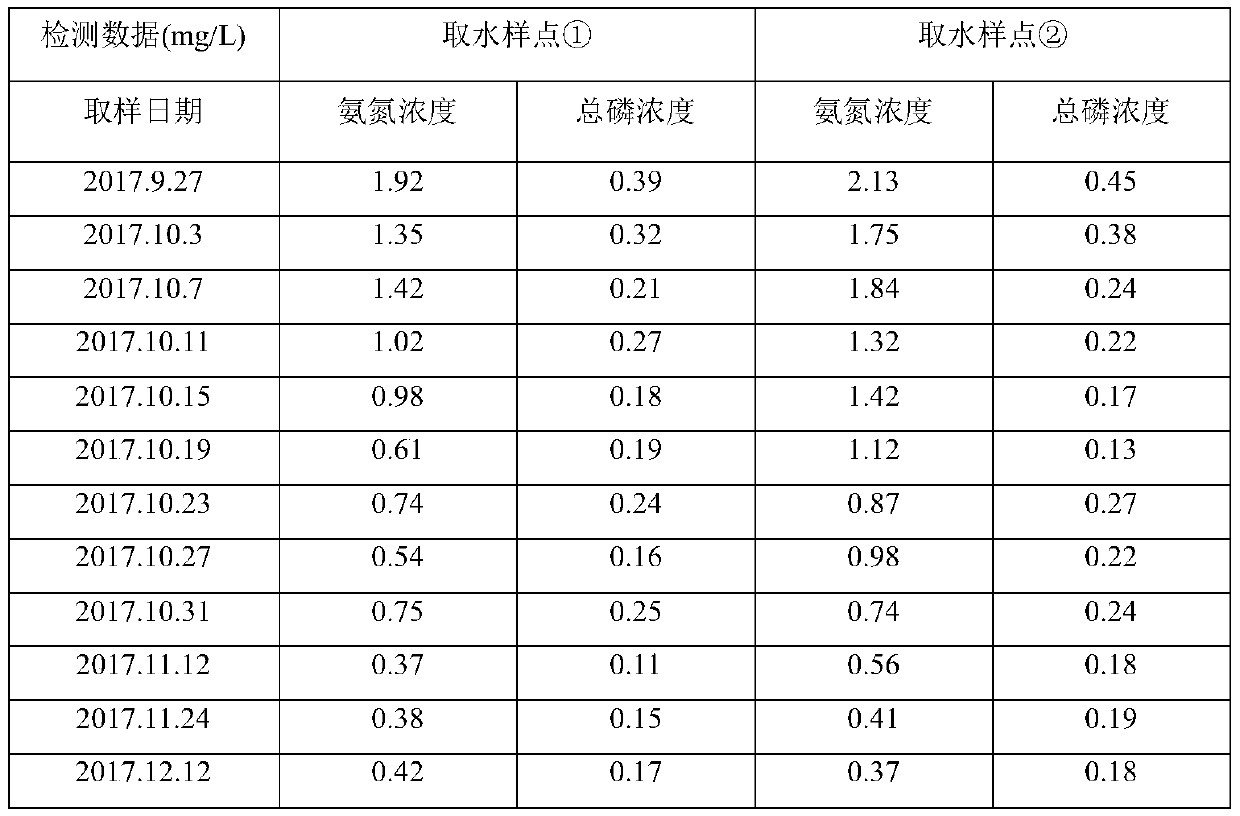

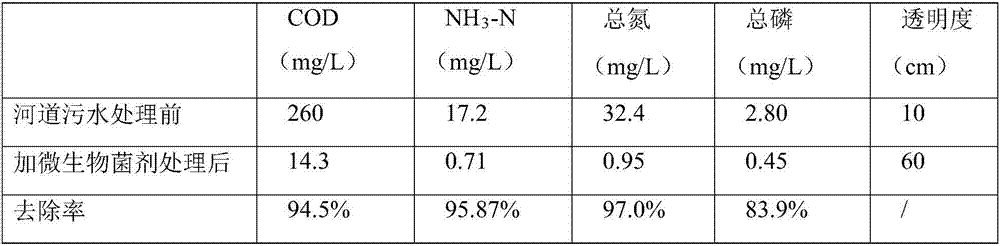

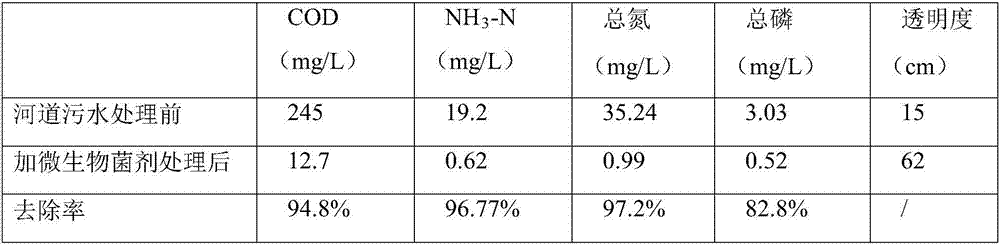

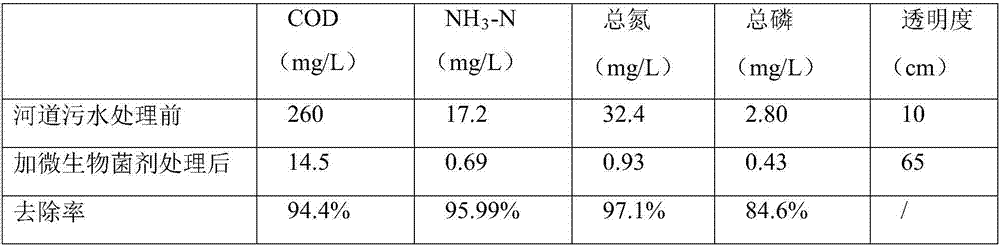

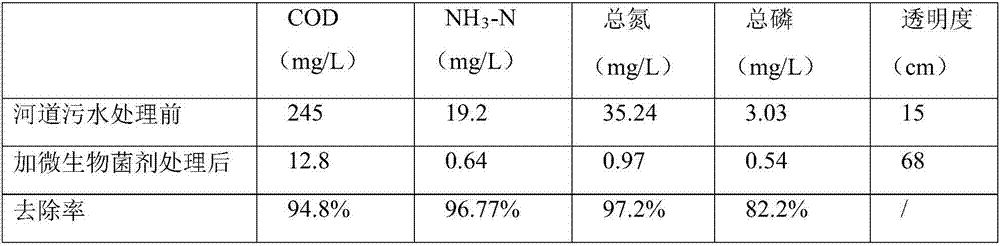

Composite microbial agent and preparation method and application thereof

InactiveCN106906170AReduce phosphorus concentrationGrowth inhibitionBacteriaMicroorganism based processesBacillus licheniformisMicrobial agent

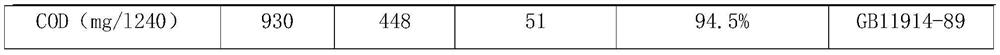

The invention discloses a composite microbial agent and a preparation method and application thereof. The composite microbial agent includes a pseudomonas preparation, an acinetobacter preparation, a bacillus amyloliquefaciens preparation, a bacillus subtillis preparation, a bacillus licheniformis preparation, a pediococcus acidilactici preparation, a rhodobacter sphaeroides preparation, an alkali-lake dietzia preparation and a rhodopseudomonas palustris preparation. The preparation method includes the following steps that 1, composite microbial agent components are prepared; 2, the composite microbial agent components are mixed in proportion to obtain the composite microbial agent. The composite microbial agent can simultaneously decompose different organic matter, degrade amino nitrogen and nitro nitrogen in water, reduce phosphorus concentration in the water body and inhibit the growth of algae. The composite microbial agent is used for urban-rural sewage in-situ remediation, has the advantages of being high in efficiency, quick to take effect, free of no secondary pollution, simple in operation and the like, and large-scale application and popularization are facilitated.

Owner:JIANGSU SUNTIME ENVIRONMENTAL REMEDIATION

Method for increasing sewage-reinforced biological phosphor-removing effect by resource utilizing mud organic substance

InactiveCN101070217AImprove phosphorus removal effectReduce volumeWater/sewage treatment by centrifugal separationTreatment with aerobic and anaerobic processesEutrophicationOxygen

This invention belongs to new style green technology region, concretely relates to a method of using sludge organic matter to advance biologic dephosphorization effect of sewage. Excess sludge at basicity condition is carried out anaerobic fermentation to produce organic acid; adopt guano precipitation means to reclaim nitrogen and phosphorus of organic acid; add the treatment fluid after reclaiming nitrogen and phosphorus to municipal sewage, under anaerobic-aerobic condition aerobic conditito carry out biological sewage treatment,through solid-liquid separation, the out water reaches the mark and is discharged. This invention through the method of adding excess sludge broth to sewage, not only advance the ability of microbe of synthesizing poly- hydroxy valeric acid(PHV)under anaerobic condition, advance availability of poly- hydroxy eicosanoic acid, decrease glycogen metabolization quantity, in favor of maintaining higher dephosphorization effect at aerobic condition, reduce phosphorus concentration in the out water, prevent water substance eutrophication occurring, but also decrease sludge volume, thereby decrease sludge treatment cost and pollute to environmental.

Owner:TONGJI UNIV

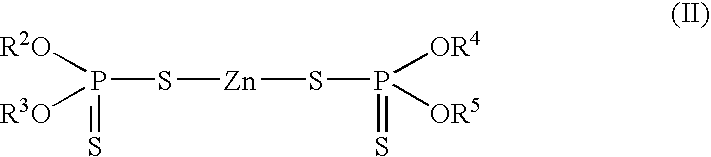

Lubricating oil composition

InactiveUS20060014653A1Good TBN retentionReduce phosphorus concentrationOrganic chemistryOrganic compound preparationChemistryInternal combustion engine

A lubricating oil composition for internal combustion engines which has a sulphated ash content of not greater than 0.9 wt. % and a phosphorus content in the range of from 0.04 to 0.1 wt. % is provided. The composition contains base oil, one or more detergents selected from phenate detergents, salicylate detergents and sulphonate detergents, wherein said one or more detergents each, independently, have a TBN (total base number) value in the range of from 30 to 350 mg.KOH / g, as measured by ISO 3771; and at least 3.5 wt. % of one or more antioxidants selected from the group of aminic antioxidants and / or phenolic antioxidants, based on the total weight of the lubricating oil composition.

Owner:SHELL OIL CO

Method of removing phosphorus from wastewater

ActiveUS7828976B2Improve concentrationReduce phosphorus concentrationSolid sorbent liquid separationSedimentation separationSludgeFerric

Owner:KRUGER I INC

Phosphorus diffusion method of crystalline silicon solar cell

ActiveCN106057980AControl concentrationConcentration Control Concurrent Reduction of Phosphorus Doping Concentration Gradients in the BodyFinal product manufactureSemiconductor/solid-state device manufacturingConcentration gradientOxygen

The present invention discloses a phosphorus diffusion method of a crystalline silicon solar cell. The method comprises the steps of (1) entering into a boat, (2) adjusting temperature to be below 800 DEG C, introducing nitrogen carrying phosphorus source and dry oxygen, and forming a silicon dioxide layer containing phosphorus, (3) carrying out low temperature diffusion, (4) raising the temperature in a furnace and pushing with the rise of the temperature, (5) carrying out first time of high temperature diffusion, (6) raising the temperature in the furnace and pushing with the rise of the temperature, (7) carrying out second time of high temperature diffusion, (8) reducing the temperature in the furnace and pushing with the decrease of the temperature, and (9) reducing the temperature and going out of the boat, and completing a diffusion process. According to the method, an oxidation gettering effect is enhanced and the concentration gradient of the phosphorus doping is controlled, the separation and collection of carriers are facilitated, the open circuit voltage is raised, the temperature difference in a cooling process is controlled, and a crystal boundary gettering effect is enhanced.

Owner:CSI CELLS CO LTD +1

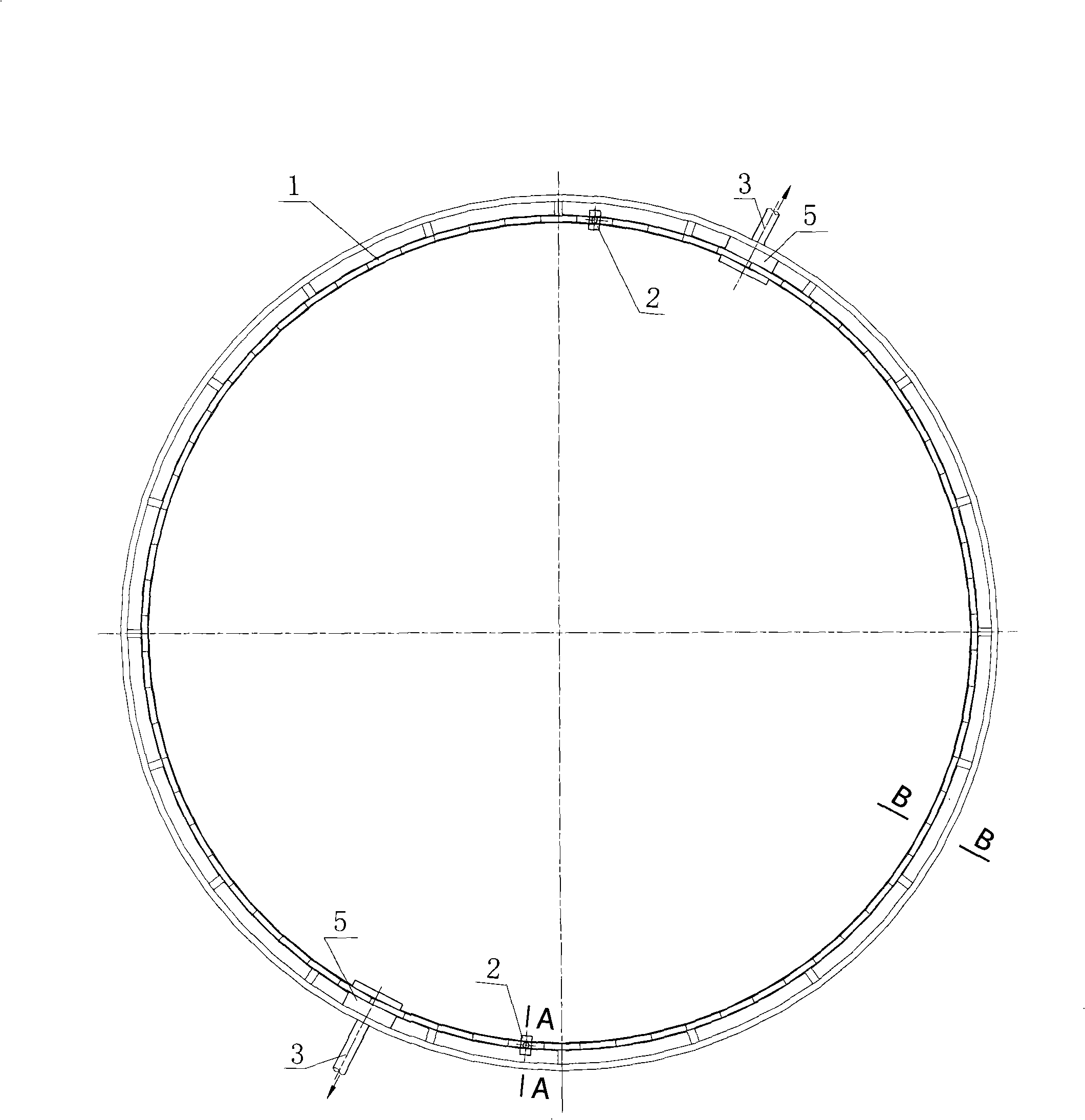

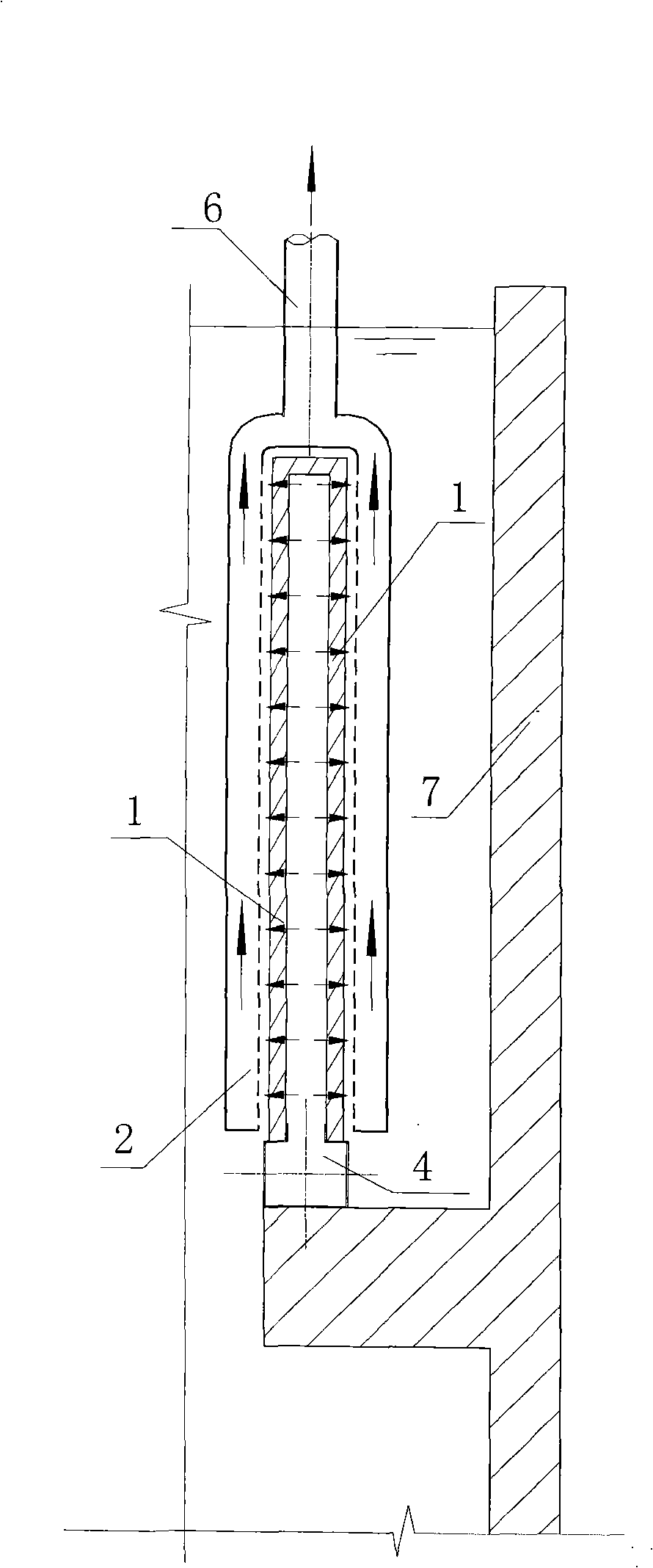

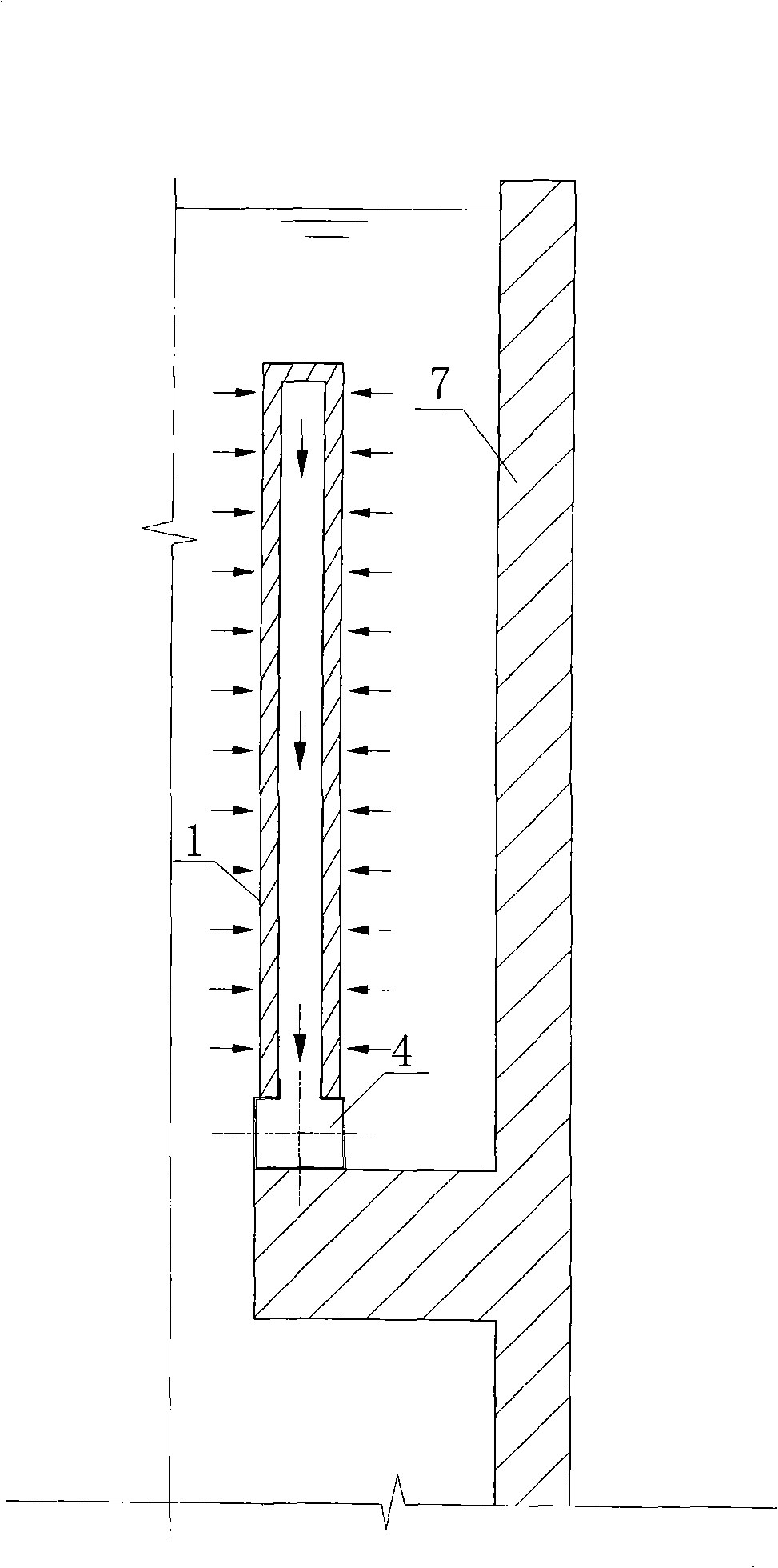

Round subsider micro-filter cloth surface filtration water exit method

InactiveCN101259339AImprove effluent qualityReduce the chromaticity of the waterWater/sewage treatmentSedimentation settling tanksProcess equipmentFiltration

The invention relates to a microfiltration cloth surface filtering water yielding method for a circular sedimentation tank, in which the water yielding is realized by a filtering system that mainly consists of a microfiltration cloth filter board (1) and an automatic cleaning device (2), wherein, the filtering system is provided with a plurality of microfiltration cloth filter boards which surround the periphery of the circular sedimentation tank and carry out the surface filtering of the sewage in the sedimentation tank, thus reducing the concentration of the suspending solids in the sewage to below 10mg / L;when the microfiltration cloth filter board is blocked up, the microfiltration cloth filter board is washed repeatedly by the automatic cleaning device, to resume the filtering function thereof. The method of the invention can improve water quality, and ensure the concentration of the suspending solids in the water to be lower than 10m / L; the method has the advantages of simple structure, convenience of installation and maintenance and low operation cost; and the backwash can be finished automatically and easily; the method can be used by old sewage treatment plant for improving the transformation of the yielding water quality standard and little changes can be done to the original technical equipment and construction; the phosphorus in the sewage can be effectively removed by using jointly with metal salt coagulant; besides, the chroma of the yielding water can also be effectively reduced.

Owner:WUHAN TEXTILE UNIV

Method of Removing Phosphorus from Wastewater

ActiveUS20110036772A1Improve concentrationReduce phosphorus concentrationSolid sorbent liquid separationSedimentation separationSludgeWastewater

A process for removing phosphorus from wastewater wherein an iron or aluminum salt is added to the wastewater. The iron or aluminum salt results in the precipitation of certain iron or aluminum species that include phosphorus adsorption sites. These iron or phosphorus species are settled and become a part of sludge produced in the course of the wastewater treatment process. By recycling substantial portions of the sludge, the concentration of these iron or aluminum species in the wastewater is increased. This increased concentration results in the presence of large quantities of unused phosphorus adsorption sites that attract and adsorb phosphorus, resulting in phosphorus being removed from the wastewater.

Owner:KRUGER I INC

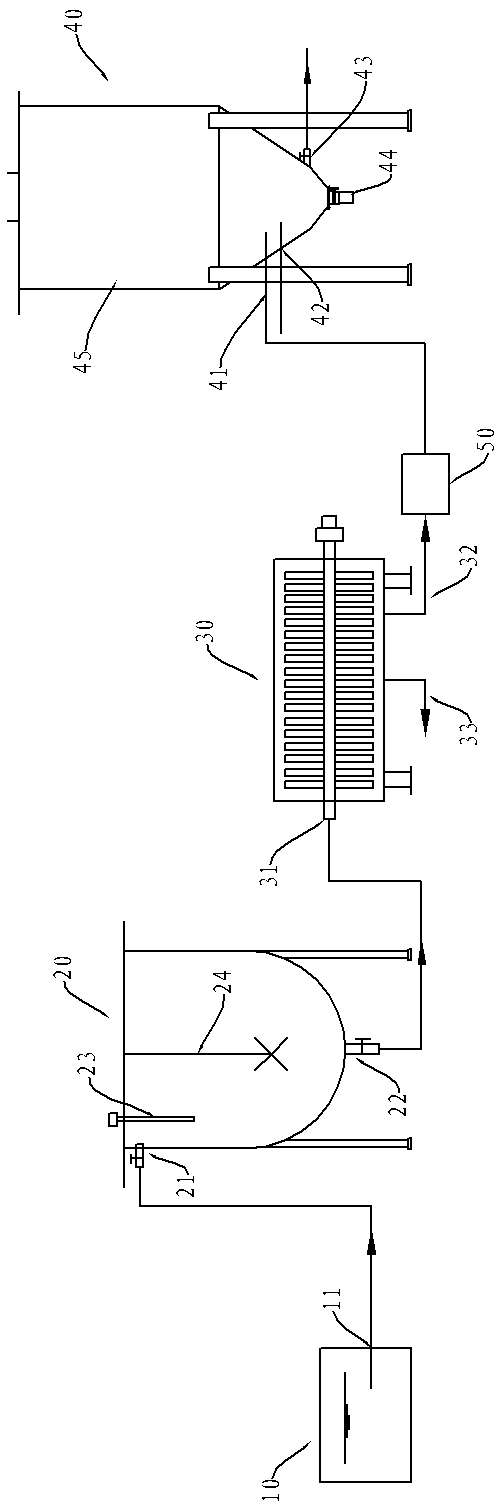

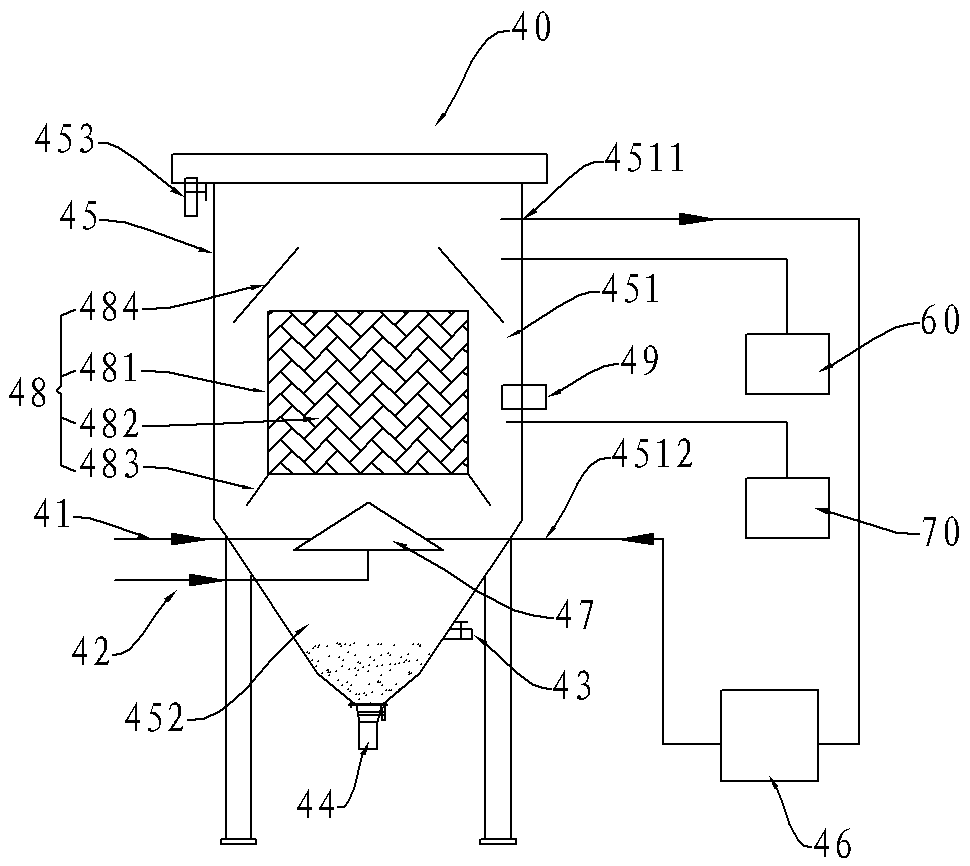

Method and system for recycling struvite from sludge

ActiveCN105502866AReduce phosphorus concentrationReduce return loadSludge treatment by de-watering/drying/thickeningWater contaminantsSolid phasesChemistry

The invention provides a method and a system for recycling struvite from sludge, and solves a problem that lots of phosphorus resources are wasted as a large number of phosphorus elements exist in a solid phase and cannot be fully released or extracted during sludge treatment. The method comprises the following steps: firstly, performing ultrasonic treatment on thick sludge in an ultrasonic reaction tank while stirring; secondly, performing solid-liquid separation treatment on the thick sludge subjected to ultrasonic treatment through a diaphragm plate-and-frame filter press to obtain a dehydrated mud cake and a filtrate, and conveying the dehydrated mud cake out to be processed; thirdly, performing secondary filtration on the filtrate through a filtering device to obtain a secondary filtrate, and mixing the secondary filtrate with a magnesium source according to a molar ratio of Mg: P of being (1.3-1.5): 1 in a struvite reaction recovery device for struvite reaction treatment, wherein the reaction treating time is controlled to be 2 hours, and in the struvite reaction treatment process, struvite particles are precipitated out from the secondary filtrate; finally, collecting the precipitated out struvite particles after the struvite reaction treatment, allowing the secondary filtrate to flow back to a sewage treatment plant to be treated further.

Owner:WUXI HUAGUANG BOILER

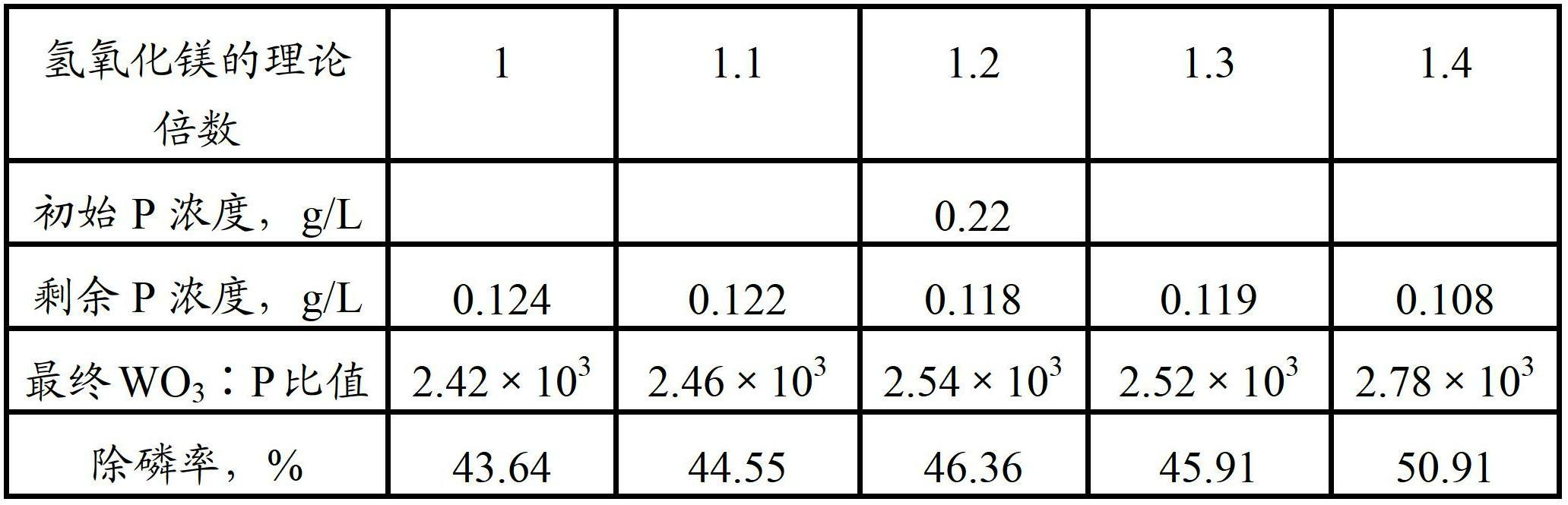

Method of purifying ammonium tungstate solution

ActiveCN102690949AImprove efficiencyReduce phosphorus contentProcess efficiency improvementMagnesium saltTungstate

The invention provides a method of purifying ammonium tungstate solution. The method comprises the following steps of contacting the ammonium tungstate solution and magnesium salt so as to remove phosphorus in a form of magnesium ammonium phosphate sediments. By utilizing the method, the phosphorus in the ammonium tungstate solution can be effectively removed.

Owner:CHONGYI ZHANGYUAN TUNGSTEN +1

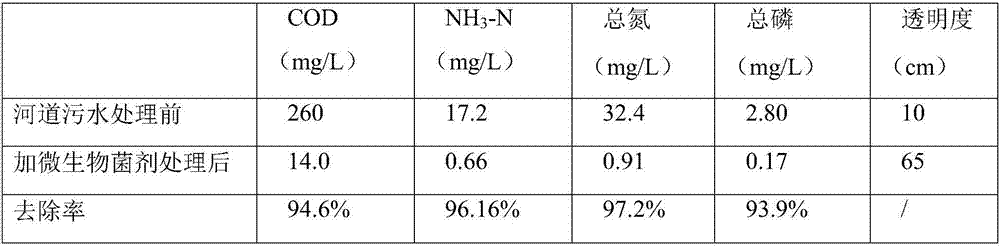

Compound microbial agent for riverway treatment and preparation method and application thereof

InactiveCN106987536AAdaptableNo inhibition of growthFungiBacteriaBacillus licheniformisSuspended particles

The invention discloses a compound microbial agent for riverway treatment and a preparation method and application thereof. The compound microbial agent comprises a microbial agent A and a microbial agent B, wherein the microbial agent A is mixed by fermentation liquor formed by independently culturing bacillus megaterium CCTCC No. M2012352, fermentation liquor formed by independently culturing bacillus subtilis CGMCC No. 1.2162, fermentation liquor formed by independently culturing bacillus licheniformis CGMCC No. 1.6510, fermentation liquor formed by independently culturing bacillus amyloliquefaciens CGMCC No. 1.7463 and fermentation liquor formed by independently culturing phanerochaete chrysosporium BKM-F1767; the microbial agent B is fermentation liquor formed by independently culturing Debaryomyces hansenii CGMCC No. 5770. The compound microbial agent can degrade amino nitrogen and nitro nitrogen in water, lower phosphorus concentration and precipitate solid suspended particles, bacterial cells and colloid particles.

Owner:XIANGTAN ZHILIAN TECH MATASTASIS PROMOTE CO LTD

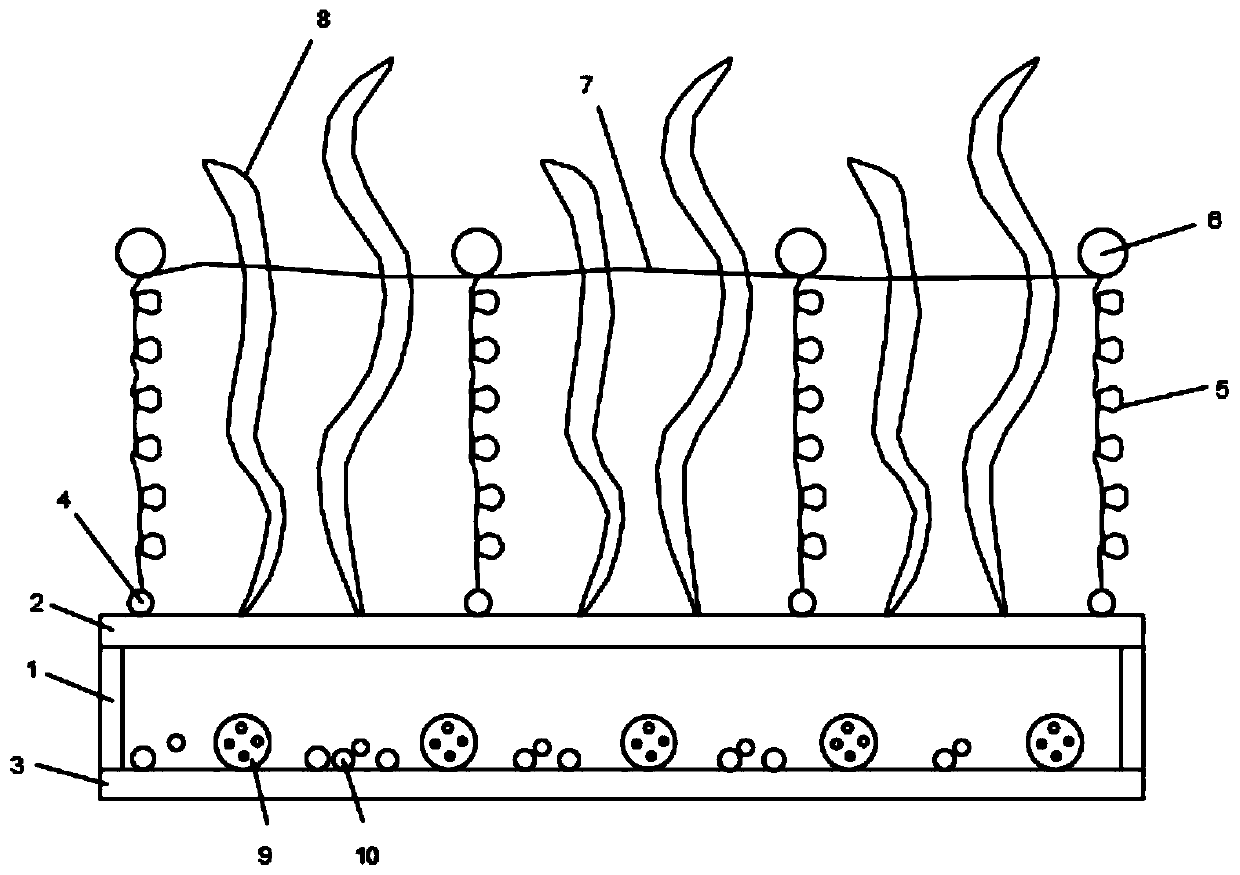

Microbial treatment method applied to riverway section restoration

InactiveCN111056645AReduce phosphorus concentrationImprove processing efficiencyWater resource protectionWater treatment compoundsEngineeringPseudomonas

The invention relates to a microbial treatment method applied to riverway section restoration. The method comprises the following steps: S1, expanding culture of a microbial liquid; S2, carrying out microbial adsorption; S3, performing internal installation and placement of an adsorption device; S4, spraying the microbial liquid; S5, detecting; and S6, carrying out analysis and adjustment. The screened complex microbial inoculant (including various strains such as efficient heterotrophic nitrification-aerobic denitrification strains-Raoultella, Pseudomonas, photosynthetic bacteria, Bacillus and the like) is used as a bacterial source, and the bacterial source is sprayed into a river channel provided with an adsorption device after culture expanding to purify overproof pollutants in river water. The riverway treatment method has the advantages of simple and convenient operation, high efficiency, good treatment effect and the like.

Owner:JIANGSU SUNTIME ENVIRONMENTAL REMEDIATION

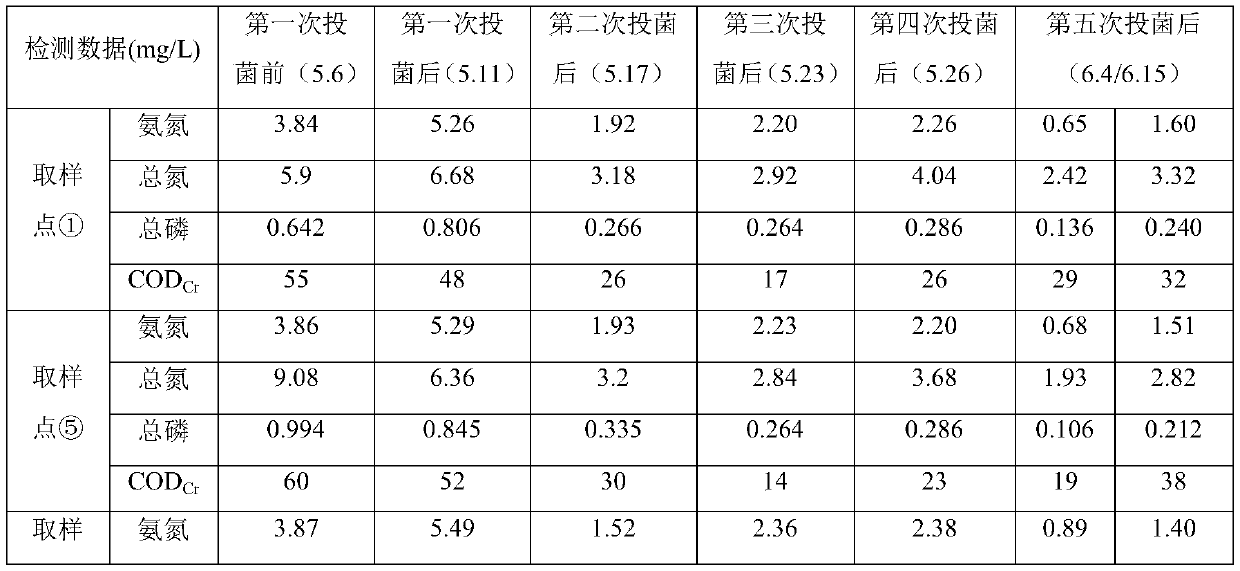

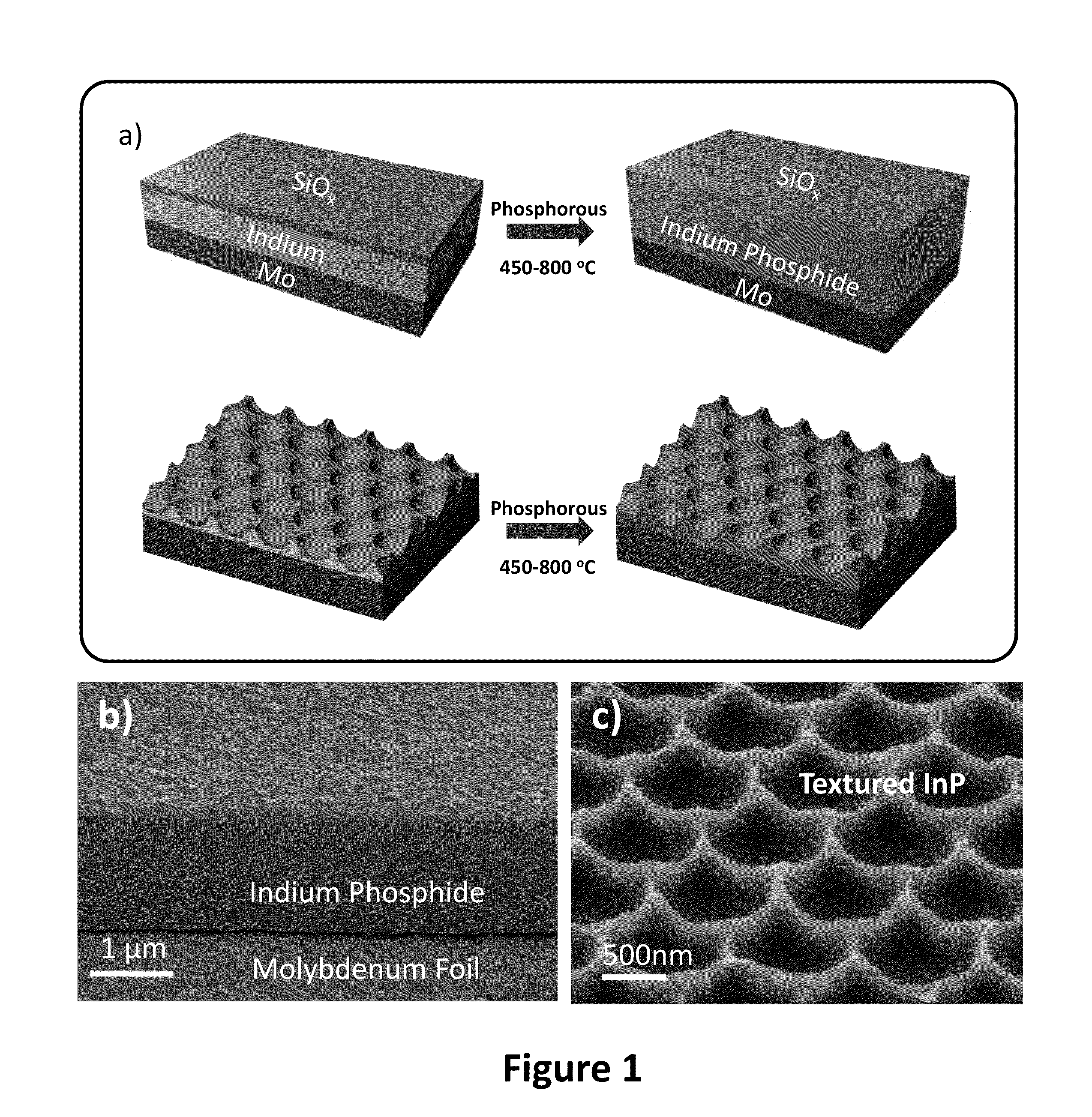

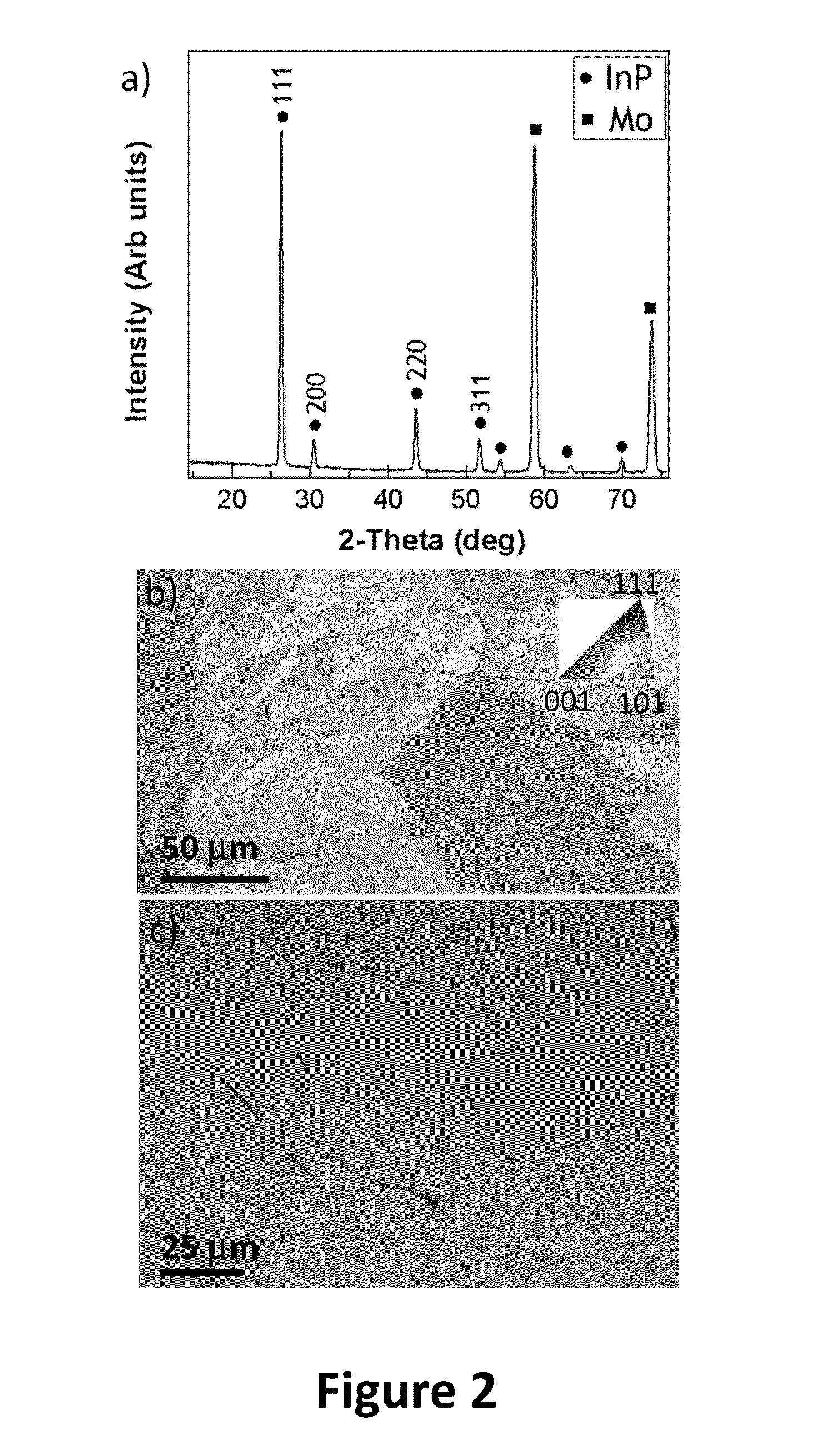

Thin film vls semiconductor growth process

InactiveUS20140290737A1Reduce morbidityReduce nucleation densityFinal product manufactureSemiconductor/solid-state device manufacturingThin oxideIndium

A composition comprising a substrate, a polycrystalline III-V semiconductor layer, and an oxide layer disposed above the polycrystalline III-V semiconductor layer is described. A growth method that enables fabrication of continuous thin films of polycrystalline indium phosphide (InP) directly on metal foils is described. The method describes the deposition of an indium (In) thin film (up to 20 microns thick) directly on molybedenum (Mo) foil, followed by the deposition of a thin oxide capping layer (up to 1 micron thick). This capping layer prevents dewetting of the In from the substrate during subsequent high temperature processing steps. The Mo / In / Capping Layer stack is then heated in the presence of phosphorous precursors, causing supersaturation of the liquid indium with phosphorous, followed by precipitation of InP. These polycrystalline III-V films have grain sizes 100-200 microns, minority carrier lifetimes >2 ns and hall mobilities of 500 cm̂2 / V-s.

Owner:RGT UNIV OF CALIFORNIA

Method for preventing scale deposition and scale inhibitor

InactiveUS20160046515A1Reduce phosphorus concentrationAvoid depositionSpecific water treatment objectivesWater contaminantsMaleopimaric acidFluorine containing

An object of the invention is to provide a method for preventing scale deposition that can prevent deposition of calcium fluoride scale without increasing phosphorus concentration in a fluorine-containing water system. Provided is a method for preventing scale deposition comprising adding a phosphorus-free maleic acid / ethyl acrylate / vinyl acetate copolymer to a fluorine-containing water system. The phosphorus-free copolymer is preferably a polymer obtained by copolymerization of monomer components containing maleic acid at a rate of 60 mol % or more, ethyl acrylate, and vinyl acetate. It preferably has a weight-average molecular weight of 500 to 5000.

Owner:KURITA WATER INDUSTRIES LTD

Carbon-based adsorbent for removing phosphate in solution

PendingCN111644158AReduce phosphorus concentrationReduce pollutionOther chemical processesWater contaminantsEutrophicationPhosphate

The invention discloses a carbon-based adsorbent for removing phosphate in a water body. The carbon-based adsorbent is prepared by the following method of: (1) uniformly mixing a biomass raw materialand a mineral material according to a weight ratio of 1-5:1, feeding the mixture into a carbonization furnace for carbonization, and performing crushing to obtain mineral material modified biochar; (2) carrying out dilute alkali treatment on the mineral material modified biochar; and (3) adding 1kg of agar, 0.5-1kg of starch and 1-3kg of a primary carbon-based adsorbent into 40-60L of deionized water, carrying out ultrasonic dispersion, performing heating to 50-60DEG C, conducting stirring and mixing, and performing natural cooling to obtain a gel. The adsorbent has a good effect of adsorbingand removing excessive phosphate in a water body, can adsorb phosphate in the water body, reduce the phosphorus concentration in the water body and relieve agricultural non-point source pollution, eutrophication and other water body pollution, is easy to separate from the water body, and can be used as a soil conditioner.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

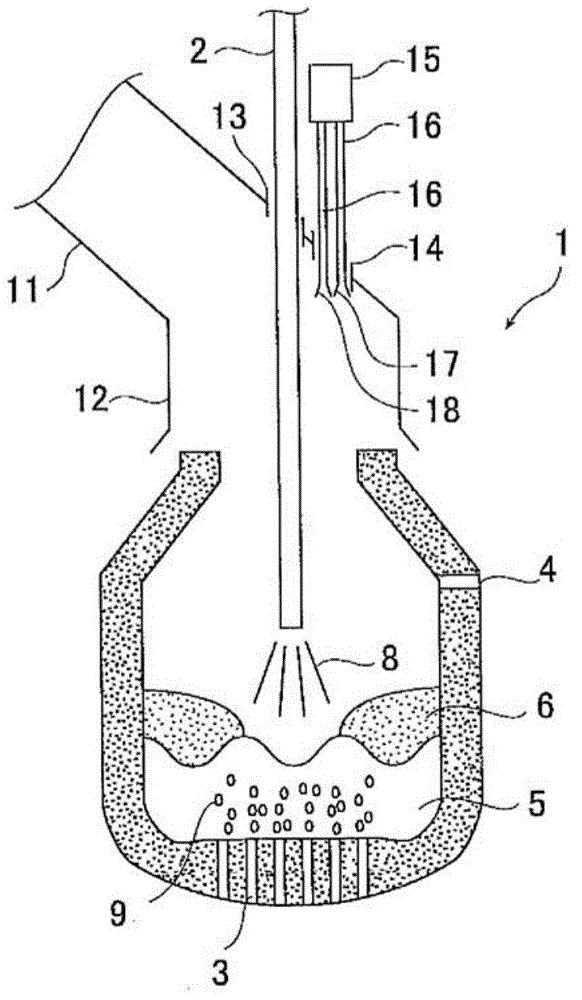

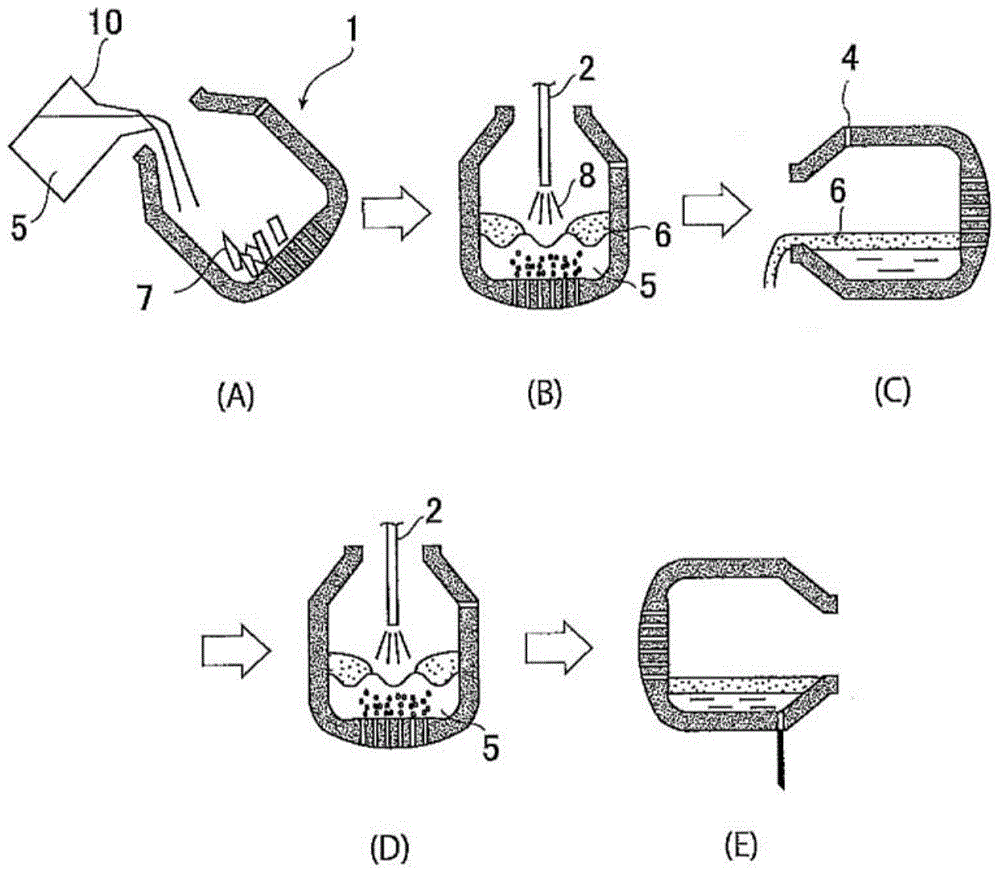

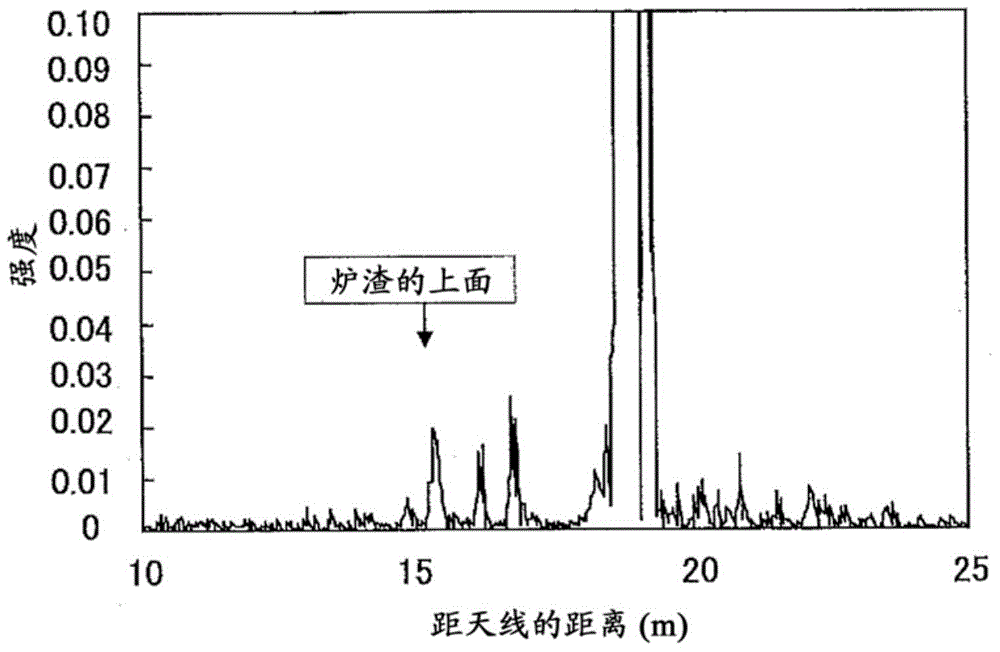

Preliminary processing method for molten iron

ActiveCN104955965AReduce phosphorus concentrationSuppression of bump effluxManufacturing convertersPretreatment methodSlag

In the present invention, when using one converter-type smelting furnace to continuously carry out molten iron desiliconization processing and dephosphorization processing with a midway slag discharge step therebetween, in the slag discharge step a sufficient amount of slag is promptly discharged to the outside of the furnace, and sufficient dephosphorization processing in terms of cost and quality is carried out. Provided is a preliminary processing method having the following: a desiliconization step for desiliconizing molten iron (5) by supplying a gaseous oxygen source from a top blowing lance (2) to the molten iron (5) in a converter-type smelting furnace; a slag discharge step for discharging from the converter-type smelting furnace at least a portion of the slag generated by the desiliconization step; a dephosphorization processing step for, after the slag discharge step, dephosphorizing the remaining molten iron by adding a CaO solvent into the converter-type smelting furnace and supplying the gaseous oxygen source from the top blowing lance. During the desiliconization, the slag height in the furnace is measured, and in a state where the measured slag height is in a predetermined range of proportion to a free board in the furnace defined by the distance from the molten iron bath surface to the furnace throat, the desiliconization processing is stopped.

Owner:JFE STEEL CORP

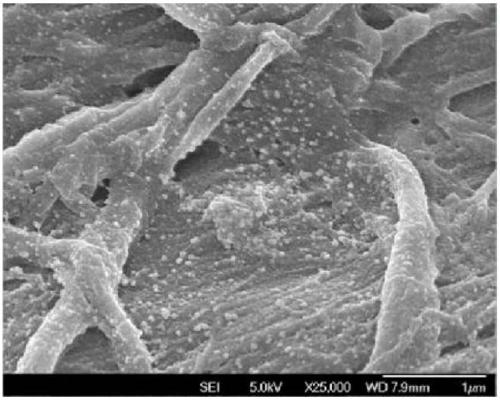

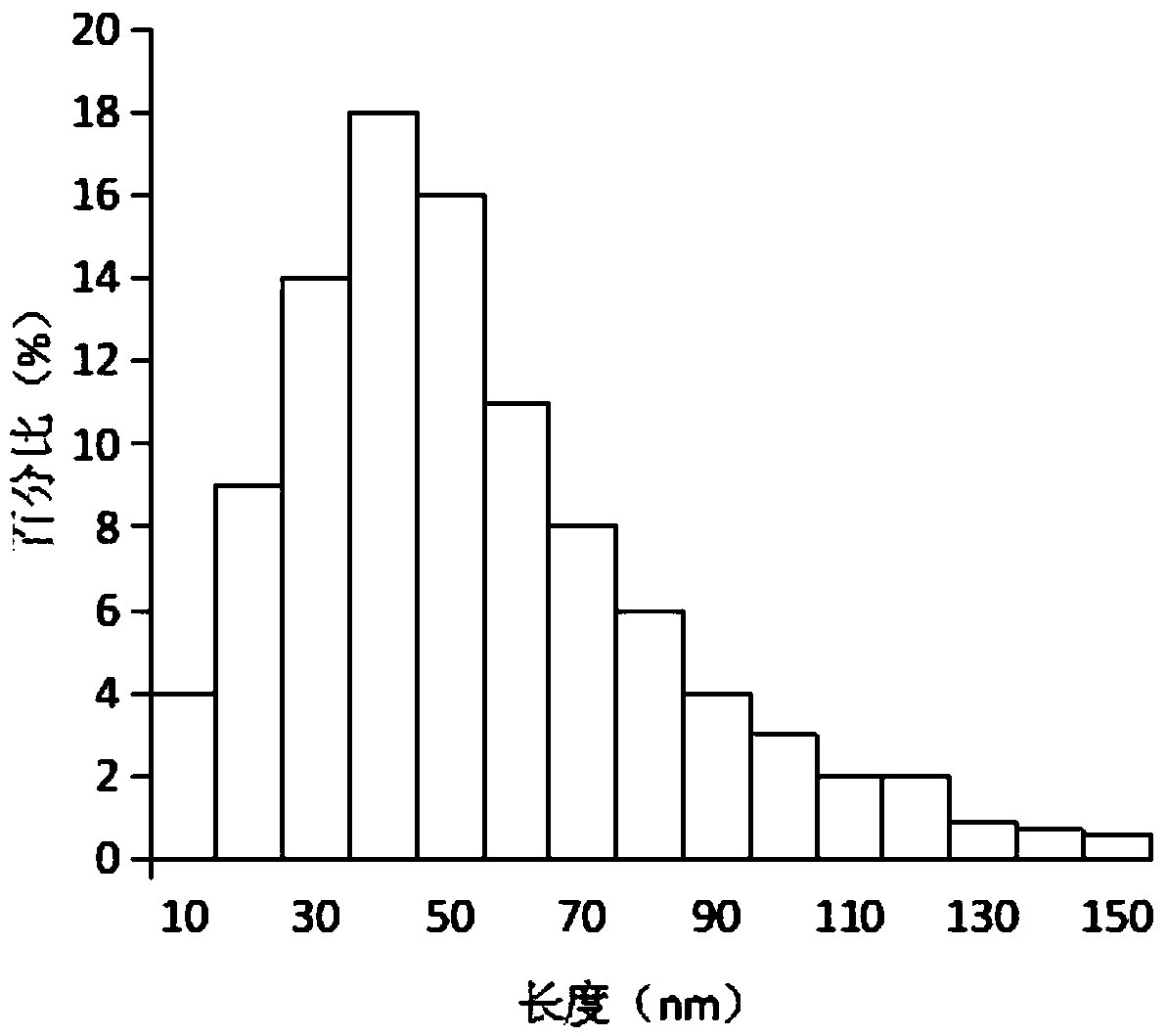

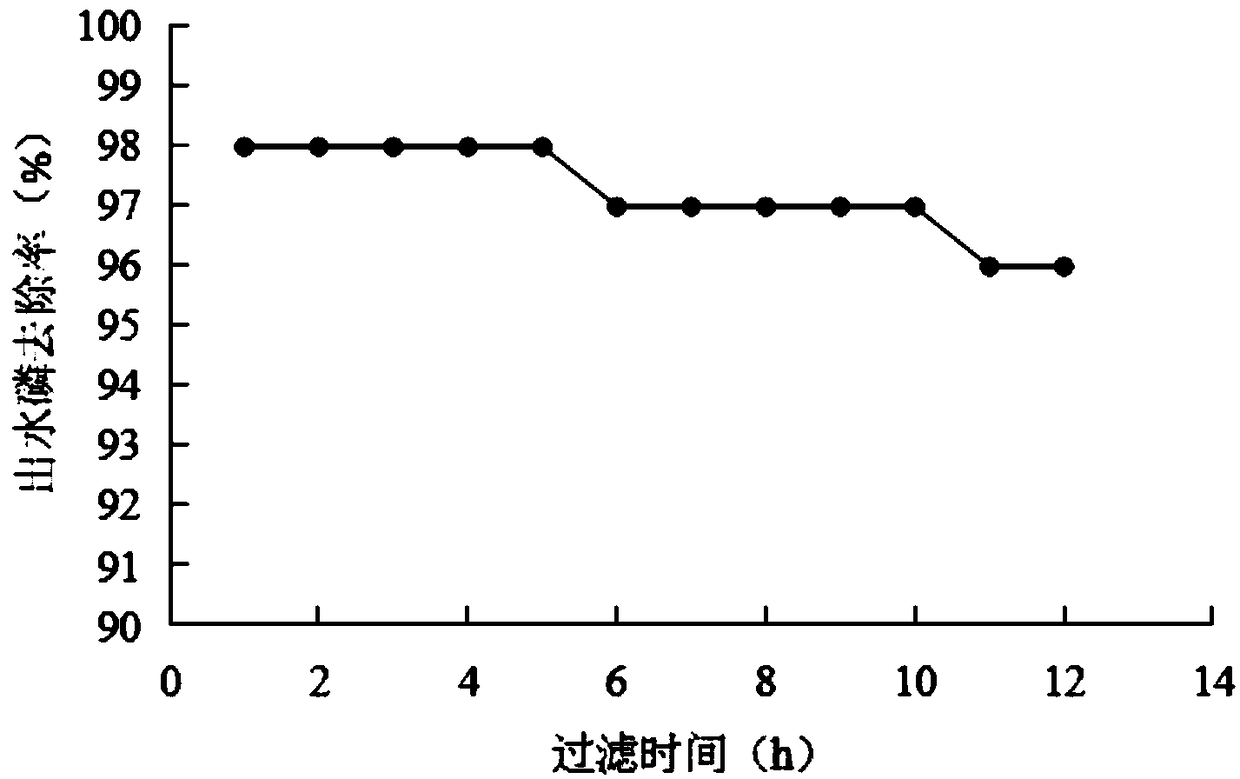

Phosphorous removal and bacterium control type PP cotton filter element and preparation method thereof

InactiveCN109260824AInhibition of growth and reproductionGood antibacterial effectTreatment involving filtrationMembrane filtersSodium hydroxideFilter element

The invention relates to a phosphorous removal and bacterium control type PP cotton filter element and a preparation method thereof. The preparation method comprises the following steps of uniformly dispersing Fe(NO3)3.6H2O and La(NO3)3.6H2O powder with a certain ratio into polypropylene molten at the temperature of 166-200 DEG C, performing wire jetting with a wire drawing machine, soaking wiresinto a sodium hydroxide solution with the concentration being 1-5 percent, producing Fe(OH)3 and La(OH)3 particles on the surfaces of polypropylene fibers in situ, and performing traction and pressingon the nano-particle loaded polypropylene fiber filaments to prepare a tubular filter element. The filter element removes phosphorus nutritive salt in water through adsorption to achieve the purposeof inhibiting growth of bacteria, and thus solving the problem that the concentration of the bacteria is increased in the long-time use process of a domestic water purifier.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

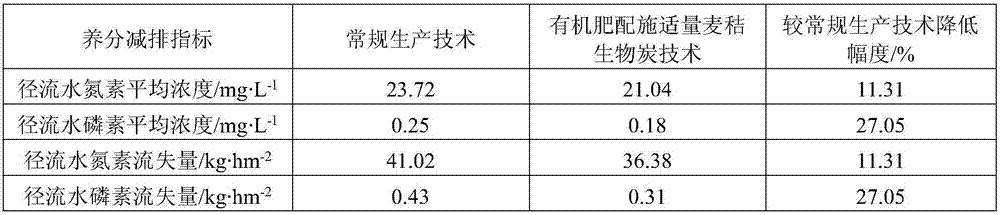

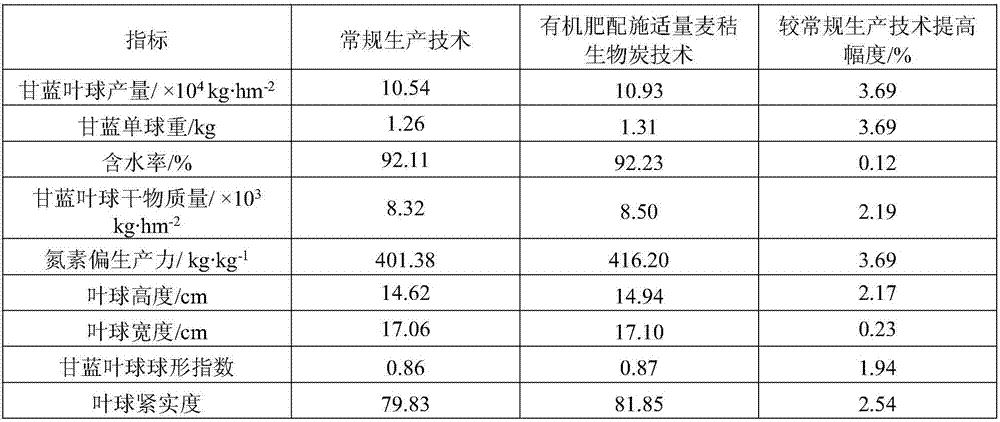

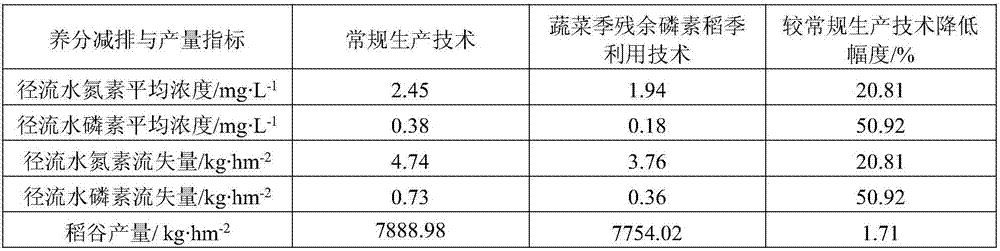

Method for nutrient emission reduction and crop stable yield maintenance in vegetable and rice crop rotation field

InactiveCN107056505AThe product is in good conditionSimple and fast operationExcrement fertilisersFertilising methodsLoss rateGrowing season

The invention discloses a method for nutrient emission reduction and crop stable yield maintenance in a vegetable and rice crop rotation field and belongs to the technical field of agricultural non-point source pollution control and crop production. Particularly, in the production process of the vegetable and rice crop rotation field, the effects of vegetable and rice crop rotation field soil runoff nitrogen and phosphorus nutrient emission reduction, crop stable and high yields and commodity character improvement are realized by the aid of the vegetable season appropriate biochar combined application technology and the vegetable season residual phosphorus rice season utilization technology. With the adoption of the technology, the rice crop rotation field soil runoff water nitrogen and phosphorus concentrations are reduced by 20.81% and 50.92% respectively, and the rice whole growing season nitrogen and phosphorus loss amounts are remarkably reduced by 20.81% and 50.92% respectively. Further, with the adoption of the technology, the vegetable and rice crop rotation field nitrogen and phosphorus runoff annual loss amounts are remarkably reduced by 12.88% and 42.24% respectively, and the vegetable and rice crop rotation field nitrogen and phosphorus runoff loss rates are remarkably reduced by 12.28% and 20.88% respectively. At the same time, with the adoption of the technology, the crop high and stable yields can be maintained, the cabbage head sphericity index and the compactness are improved by 1.94% and 2.54% respectively, and the cabbage commodity character is remarkably improved.

Owner:JIANGSU ACAD OF AGRI SCI

Modified red earth flocculant and method for preparing same

InactiveCN103241819AReduce dosageImprove phosphorus removal effectWater/sewage treatment by flocculation/precipitationSludgeTap water

The invention discloses a modified red earth flocculant and a method for preparing the same. Raw materials comprise red earth, acids and tap water. The method comprises the steps: firstly, the acids and the water are mixed to form a dilute acid according to a ratio; then the dilute acid and the red earth are mixed so as to obtain an acid and earth mixture; and the acid and earth mixture is dried, grinded and sieved, and the obtained undersize product is the modified red earth flocculant. The raw materials which are used according to the method disclosed by the invention are extensive, the production process is simple, the cost is low, and the product is non-toxic and does not generate secondary pollution. When the flocculant is used for treating sludge, the input of the flocculant is less, the settlement speed of the sludge is fast, and the moisture content of treated sludge is low. The flocculant also has a relatively good phosphorus removal effect, and is economical, practical and environment-friendly.

Owner:YUXI NORMAL UNIV

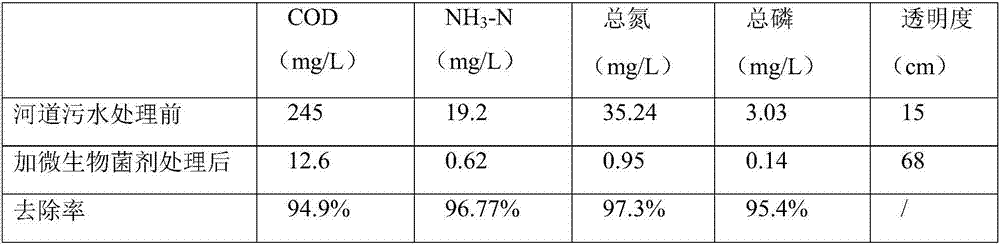

Compound microbial agent for river regulation, preparation method of compound microbial agent and river sewage treatment method

InactiveCN106987535AAdaptableGrowth inhibitionFungiBacteriaBacillus licheniformisSuspended particles

The invention discloses a compound microbial agent for river regulation, a preparation method of the compound microbial agent and a river sewage treatment method. In the compound microbial agent, a microbial agent A is made by mixing of five fermentation liquors formed by single culture of bacillus megaterium CCTCC NO.M2012352, bacillus subtillis CGMCC NO.1.2162, bacillus licheniformis CGMCC NO.1.6510, bacillus amyloliquefaciens CGMCC NO.1.7463 and phanerochaete chrysosporium BKM-F1767; a microbial agent B is made by mixing of two fermentation liquors formed by single culture of debaryomyces hansenii CGMCC NO.5770 and saccharomyces cerevisiae CGMCC NO.3003. The compound microbial agent has advantages that amino nitrogen and nitro nitrogen in water can be degraded, phosphorus concentration is decreased, and precipitation of solid suspended particles, bacterial cells and colloid particles in water is realized.

Owner:XIANGTAN ZHILIAN TECH MATASTASIS PROMOTE CO LTD

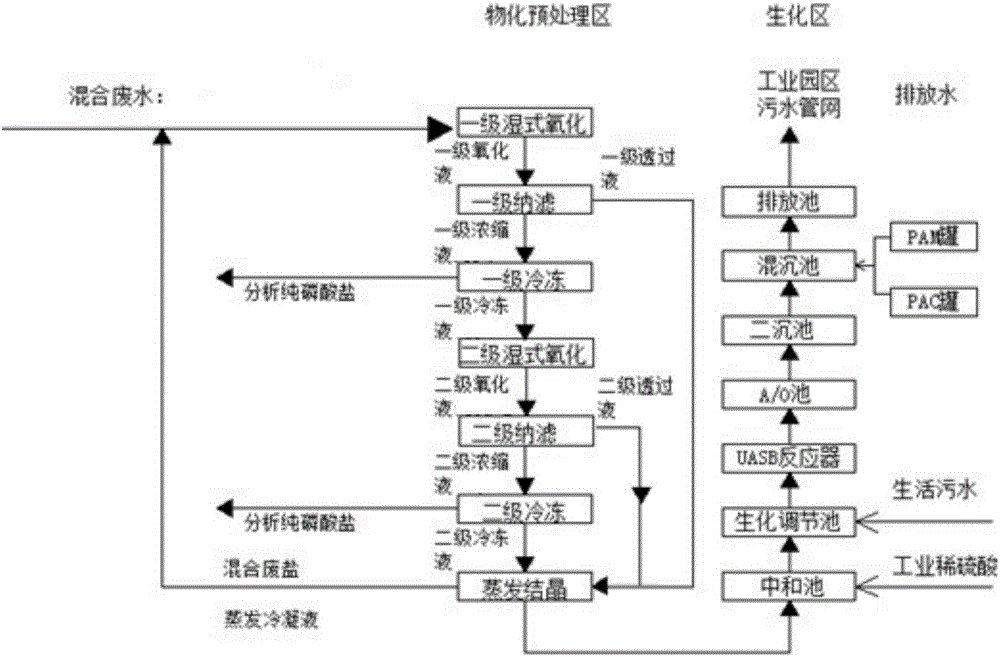

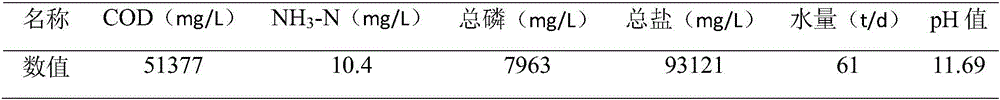

Imidazole aldehyde waste water treatment process and operating method thereof

ActiveCN106746347AEasy to handleRealize recycling of resourcesWater treatment parameter controlWater contaminantsSludgeWaste treatment

The invention discloses an imidazole aldehyde waste water treatment process and an operating method thereof, and belongs to the technical field of waste water treatment. The treatment process provided by the invention comprises primary wet oxidation, primary nanofiltration, primary freezing, secondary wet oxidation, secondary nanofiltration, secondary freezing and evaporative crystallization, wherein a biochemical area comprises a pH neutralizing pool, a biochemical adjusting pool, a UASB reactor, an A / O pool, a secondary sedimentation pool and a mixed sedimentation pool. Through physical and chemical pretreatment of midazole aldehyde waste water, the COD concentration can be greatly reduced to 3000 mg / L, pure organic P can be recycled, and the residual organic P is transformed into inorganic P, so that removal of P from the midazole aldehyde waste water by the biochemical area is enhanced. After waste water subjected to physical and chemical pretreatment and domestic waste water are mixed, the COD and the P are removed from the waste water through biochemical treatment; and PAC and PAM are emergently added in the mixed sedimentation pool to enhance removal of COD and P precipitate, so that reduction of the biochemical action of the active sludge in the biochemical area in winter is avoided, and the midazole aldehyde waste water is efficiently removed.

Owner:江苏南大华兴环保科技股份公司

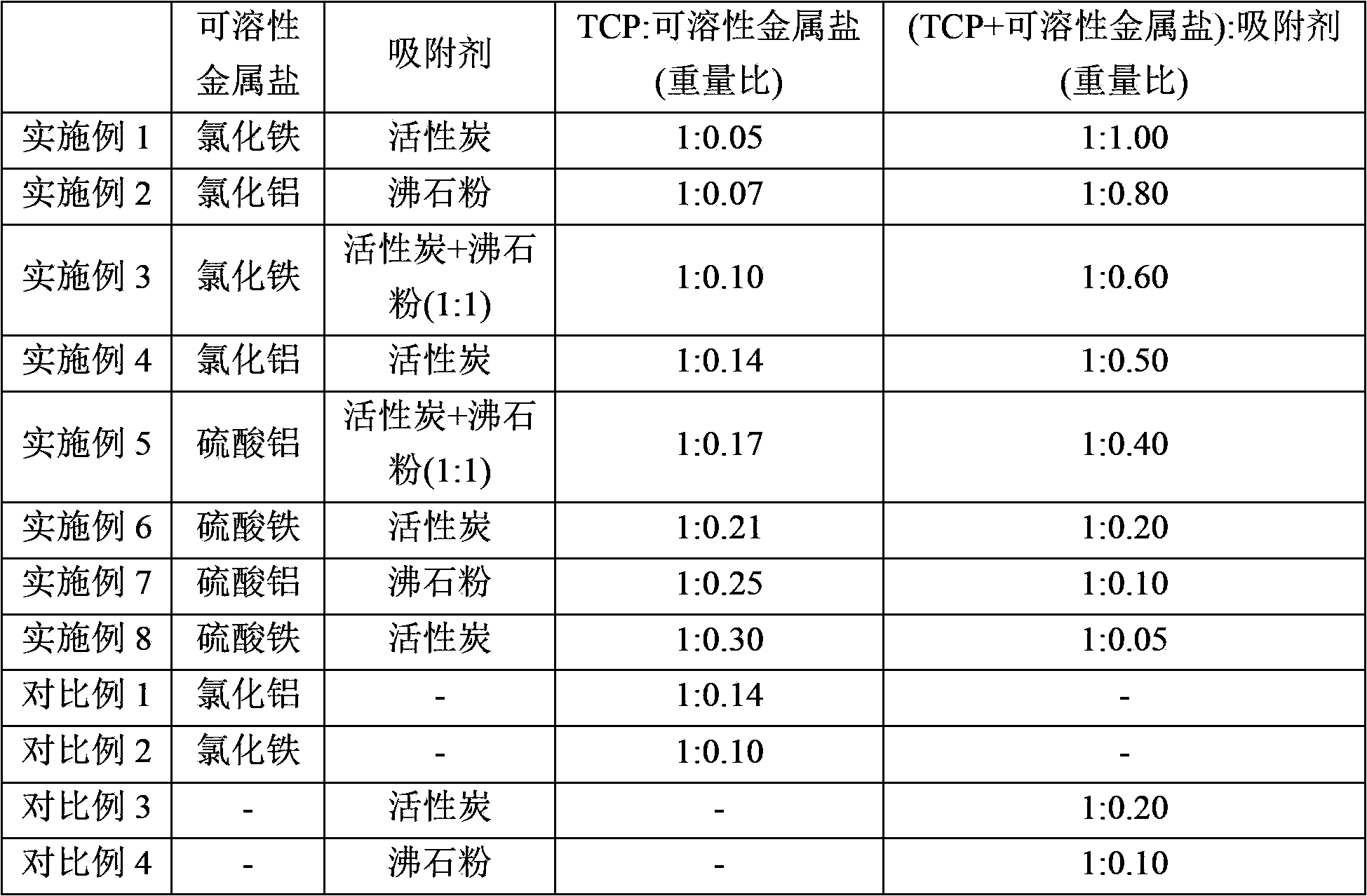

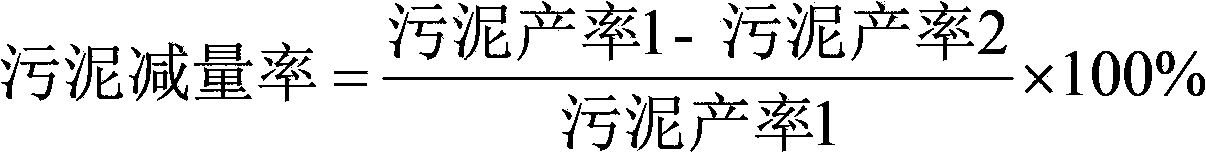

Uncoupling agent and application thereof

ActiveCN103771579AGood sludge reduction performanceReduce total phosphorus concentrationSustainable biological treatmentBiological water/sewage treatmentReduction rateAluminium

The invention relates to an uncoupling agent containing 2,4,5-trichlorophenol, a soluble metal salt and an adsorbent, wherein the soluble metal salt is soluble ferric salt and / or soluble aluminum salt. The invention also relates to the application of the uncoupling agent to an activated sludge method for the treatment of wastewater. In the process of the activated sludge method for the treatment of wastewater, the uncoupling agent provided by the invention can realize high COD removal rate and sludge reduction rate, and the water outlet has small TP concentration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for efficient in-situ control of sludge endogenous pollution

ActiveCN107759040AImprove solubilityLess restrictiveWater treatment parameter controlSludge treatment by oxidationIn situ remediationSludge

The invention discloses a method for efficient in-situ control of sludge endogenous pollution, and belongs to the field of environmental engineering water treatment. Aiming at the problem that river channel sludge endogenous pollution is difficult to efficiently control, the invention provides a method for efficient in-situ control of sludge endogenous pollution. The method basically comprises thesteps of adopting a combination of a phoslock, calcium peroxide and aluminum modified zeolite, performing sludge in-situ remediation, and efficiently restraining sludge endogenous pollution. The method is convenient for the ecological control of polluted water for the next step, and finally realizes long term improvement of water pollution conditions.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Composite microbial agent for river treatment and preparation method and application thereof

The invention discloses a composite microbial agent for river treatment and a preparation method and application thereof. According to the composite microbial agent, an agent A is formed by mixing five fermentation liquids formed by individual cultivation of a bacillus megatherium CCTCC No.M2012352, a bacillus subtillis CGMCC No.1.2162, a bacillus licheniformis CGMCC No.1.6510, a bacillus amyloliquefaciens CGMCC No.1.7463 and a phanerochaete chrysosporium BKM-F1767; and an agent B is a fermentation liquid formed by individual cultivation of a debaryomyces hansenii CGMCC No.5770. The composite microbial agent is capable of degrading amino nitrogen and nitro nitrogen in water, reducing the phosphorus concentration and precipitating solid suspended particles, somatic cells and colloid particles in water.

Owner:XIANGTAN ZHILIAN TECH MATASTASIS PROMOTE CO LTD

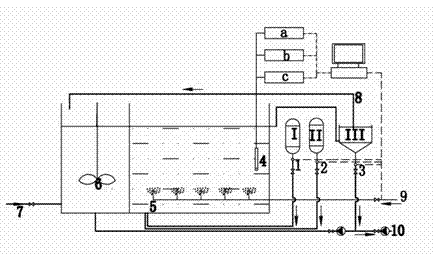

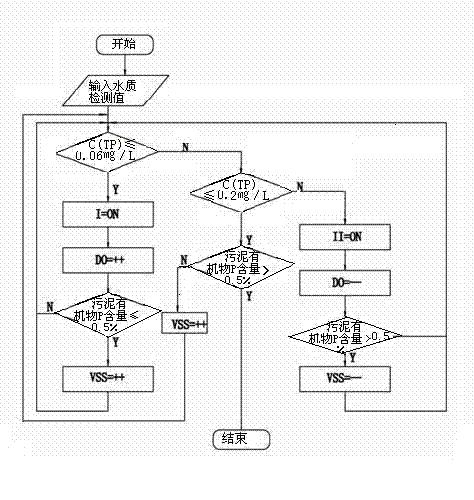

Short-distance nitrification denitrification nitrogen removal technology control method

InactiveCN103708612AIncrease concentrationReduce concentrationTreatment with anaerobic digestion processesNitrogen removalSludge

The invention relates to a short-distance nitrification denitrification nitrogen removal technology control method, aims to improve the nitrogen removal efficiency, save energy consumption, reduce sludge yield and save land occupation area, and is suitable for the treatment of industrial wastewater grossly inadequate in phosphorus content. Influences of phosphorus concentration on nitrosifying bacteria and nitrifying bacteria are different, phosphorus subsaturation coefficient for the nitrifying bacteria is one magnitude order higher than the phosphorus subsaturation coefficient for the nitrosifying bacteria, and the method includes target water quality identification and response and mixed liquid phosphorus concentration control and adjustment processes. Short-distance nitrification denitrification is realized as follows: online testing of a reaction liquid, inputting of analysis results into a system, comparison of phosphorus response schemes, generation of a phosphorus dynamic dosing scheme, and outputting of signals of control I, II and III for regulation of the phosphorus concentration in the reaction liquid. The reaction degree of each stage of a nitrogen removal reaction is controlled by regulation of the phosphorus concentration ratio in the reaction liquid to achieve the purpose of high accumulation of nitrous nitrogen and realize the shortcut nitrification denitrification process.

Owner:SHENYANG JIANZHU UNIVERSITY

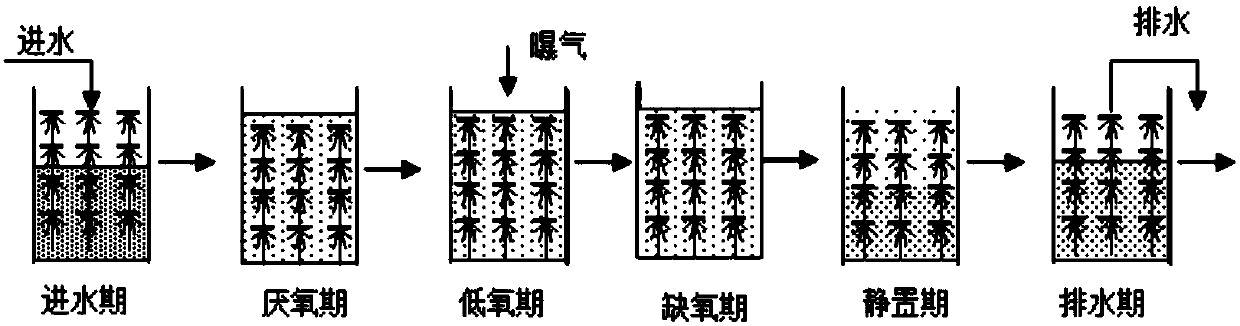

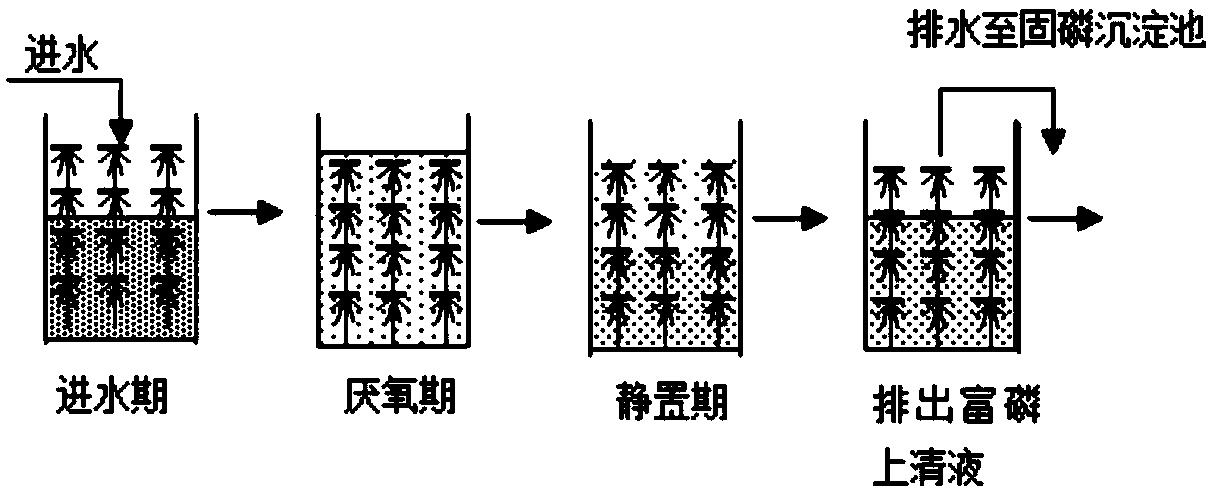

Deep nitrogen-and-phosphorus-removing technology based on SBBR

ActiveCN109607774ALimit conversionGuaranteed complete oxidationWater treatment parameter controlWater contaminantsChemistryCarbon source

The invention discloses a deep nitrogen removing technology based on a SBBR, and belongs to the technical field of environment engineering. The SBBR equipment is adopted, sewage in the SBBR runs in ananaerobic, low-oxygen and oxygen-deficit mode, PHA is stored for anaerobic-period microorganisms, and the favorable condition is provided for nitrite denitrifying phosphorus accumulating in the low oxygen period. By accurately controlling low-oxygen-period time and post-oxygen-deficit-period time, accurate controlling over the ammoxidation process and the denitrification process is achieved, andtherefore deep nitrogen removing of the sewage is achieved. When the device runs for a certain period, an external carbon source is added into a reactor for intensifying phosphorus release in the anaerobic initial stage, stirring is stopped in the anaerobic last phase, the mixed liquid is subjected to standing and settling, then phosphorus-rich supernatant is discharged into a phosphorous removingsettling pond, and water is newly fed into the SBBR to enter normal period running. A chemical phosphorus removing chemical is put into the phosphorus-rich supernatant discharged into the phosphorousremoving settling pond to generate sediment fixed phosphorus, the supernatant after being subjected to phosphorus removing enters a water feeding pond of the SBBR to be continue to treat. The efficient nitrogen-and-phosphorus-removing effect is achieved through the measures.

Owner:CHANGAN UNIV

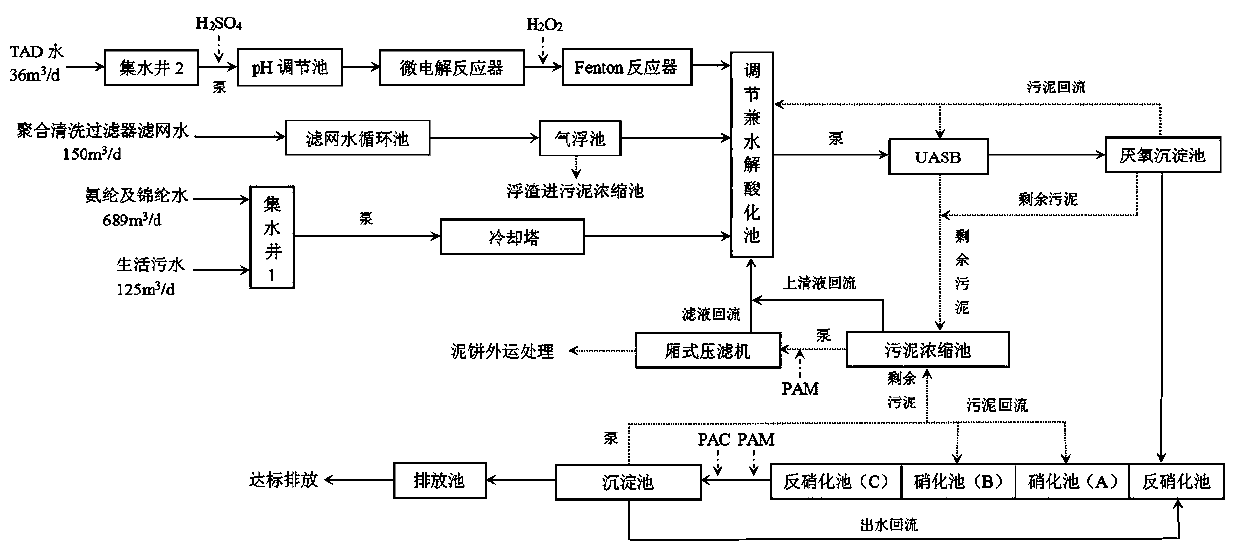

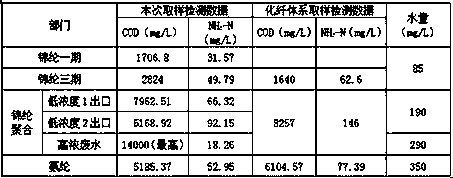

Sewage treatment system in chemical fiber factory

PendingCN109987794AEasy to handleSolve caprolactamSludge treatment by de-watering/drying/thickeningTreatment involving filtrationFiberCooling tower

The invention belongs to the field of sewage treatment in chemical fiber factories, and particularly relates to a sewage treatment system in a chemical fiber factory. Spandex, nylon and domestic sewage are collected to a sewage treatment station, waste filaments, waste blocks and other impurities are removed through a grille, the treated water flows into a water collecting well 1, then the wastewater is lifted to enter a cooling tower by a pump for cooling, and the cooled water enters a regulation and hydrolysis acidification tank; the concentration of suspended solids contained in polymerization cleaning filter screen water is higher, firstly pretreatment is performed by an air flotation device, and the pretreated water enters the regulation and hydrolysis acidification tank; the nylon polymerization discharged water contains TAD water, the TAD water is pumped into a micro-electrolysis reactor after being treated in a water collecting well 2 and a pH regulation tank for pre-treatment,the pretreated water flows into a Fenton reactor, and the outflow water enters the regulation and hydrolysis acidification tank; and after hydrolysis acidification treatment is performed, the obtained water is lifted to a UASB reaction tank through a pump, and the outflow water enters an anaerobic sedimentation tank. The system provided by the invention can effectively treat the sewage in the chemical fiber factory, and the treated sewage achieves the national emission standards in China.

Owner:云南今业生态建设集团有限公司

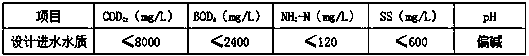

Nitrogen and phosphorus removal process based on multi-effect medical sewage treatment

ActiveCN111908705AEasy to controlProtection securitySpecific water treatment objectivesWater contaminantsSludgeEngineering

The invention relates to a nitrogen and phosphorus removal process based on multi-effect medical sewage treatment. The system comprises a mechanical grid 1, an adjusting tank 2, a first blower 3, a first pump 4, an anoxic tank 5, a contact oxidation tank 6, a second pump 7, a second blower 8, a vertical flow sedimentation tank 9, a third pump 10, a coagulation reaction tank 11, a PFS tank 12, a PAM tank 13, an inclined tube sedimentation tank 14, a fourth pump 15, a contact disinfection tank 16, a sodium hypochlorite tank 17, a sludge tank 18 and a central processor. The central processing unit is additionally arranged in the system, the water level in the designated water pool is detected, the corresponding air blower operation parameters and the corresponding dosing amount of the dosingtank are selected according to the detection result, and sludge control of the system can be effectively improved.

Owner:北京绿都浩天环保科技有限公司

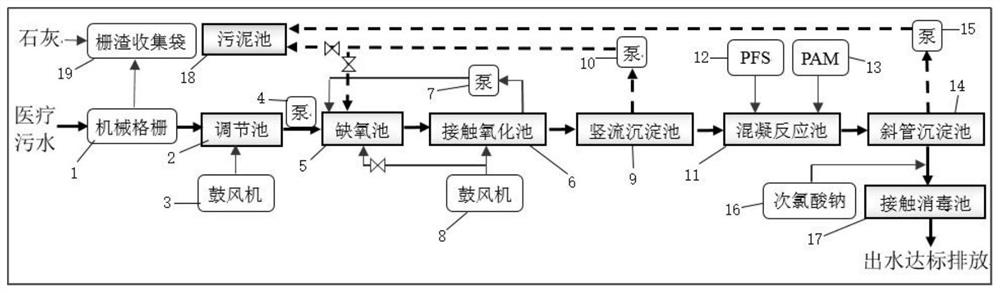

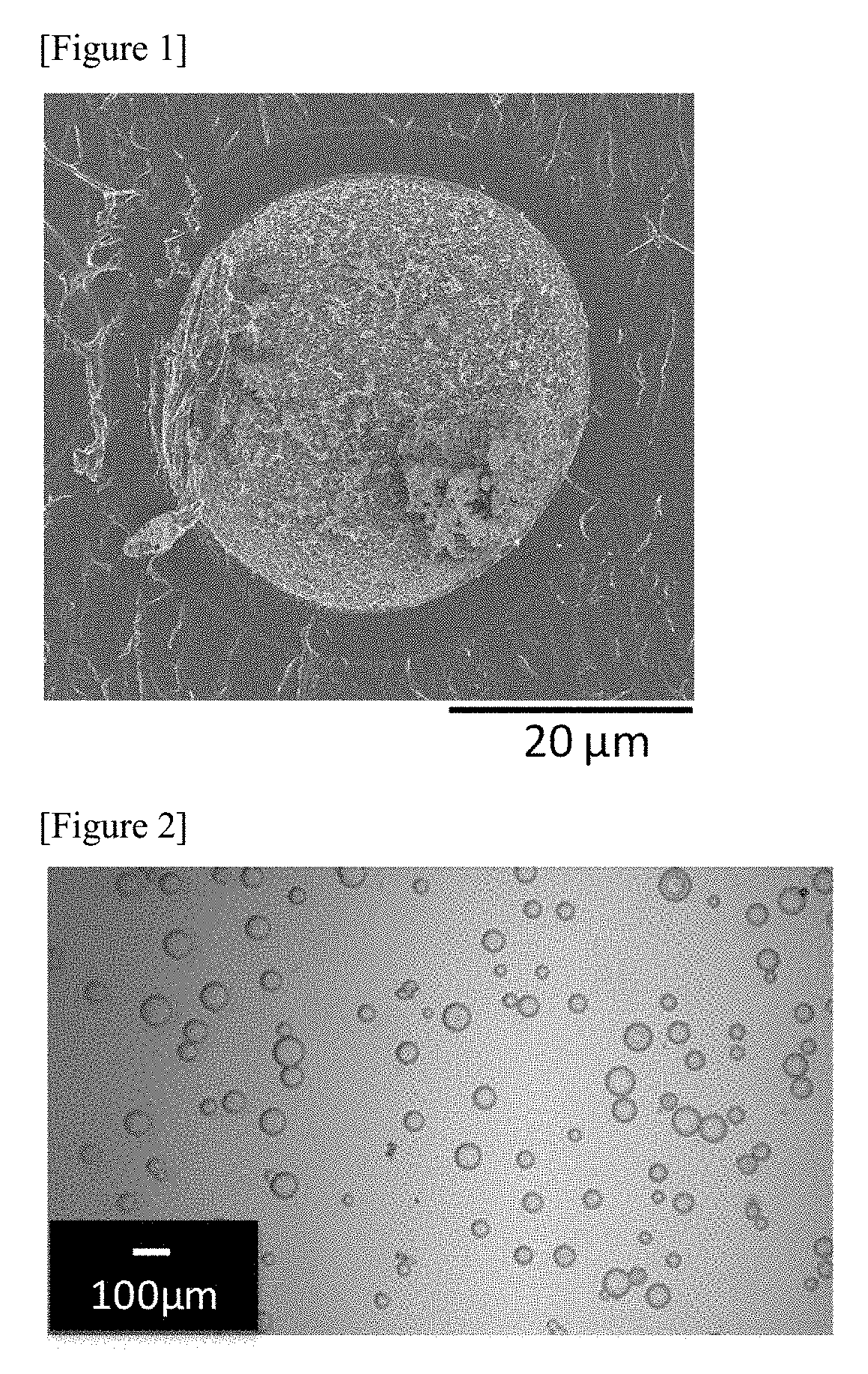

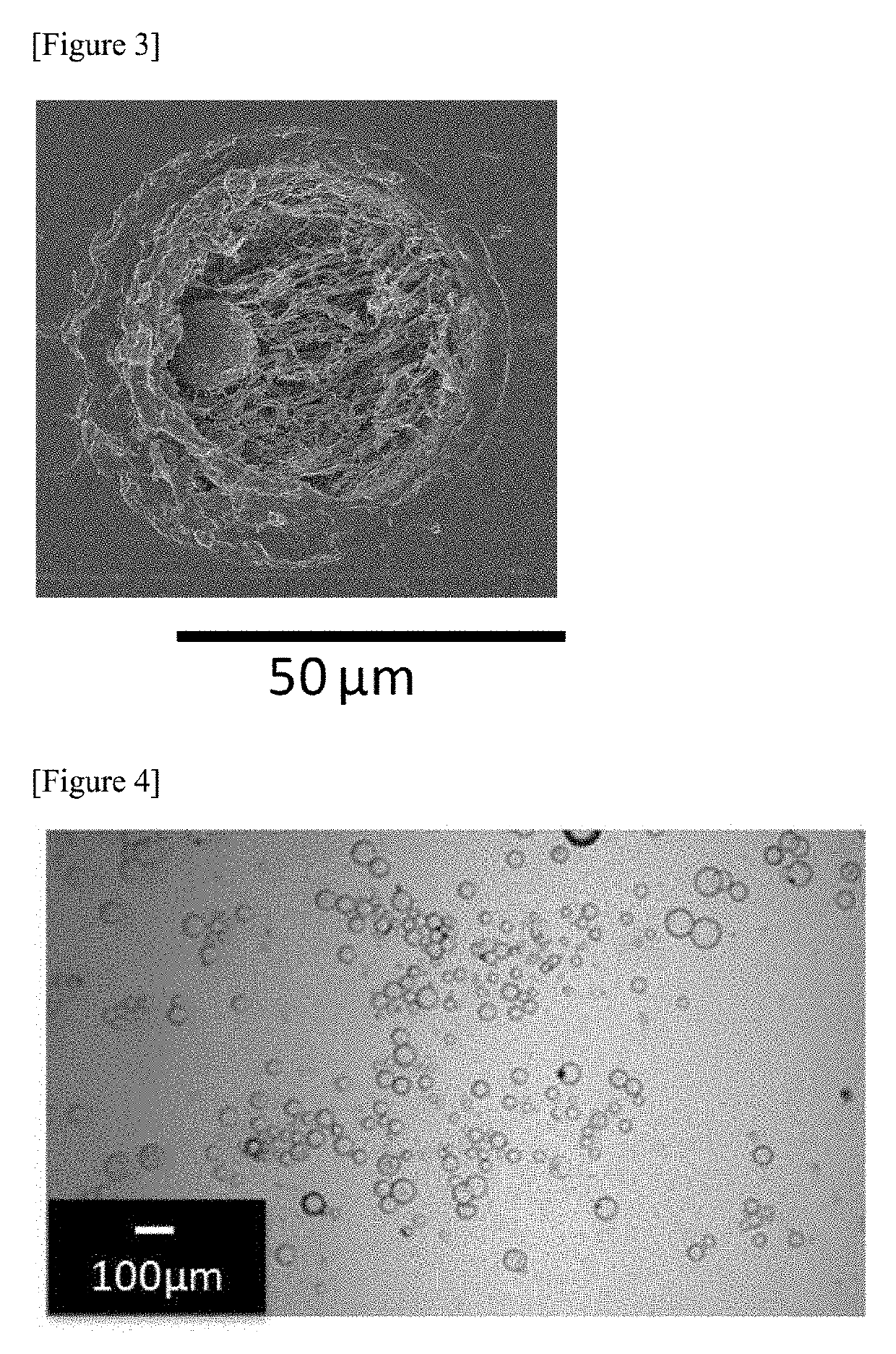

Therapeutic agent for hyperphosphatemia and particles

InactiveUS20190321393A1Improved prognosisReduce phosphorus concentrationOrganic active ingredientsPowder deliveryHydrogen atomMedicine

The object of the present invention is to provide a therapeutic agent for hyperphosphatemia capable sufficiently decreasing a serum phosphorus concentration with a small dose, and particles therefor. The present invention provides a therapeutic agent for hyperphosphatemia, which comprises, as an active ingredient, a particle containing a crosslinked polymer having a substituent containing a NRA1RA2 structure or a salt thereof, wherein the particle has an average particle diameter of 20 to 150 μm and a swelling rate of 9 to 16 mL / g (wherein RA1 and RA2 each independently represent a hydrogen atom, an alkyl group having 1 to 20 carbon atoms, an aminoalkyl group having 1 to 20 carbon atoms or a salt thereof, or the like).

Owner:FUJIFILM CORP +1

Zeolite immobilized microorganism and plant combined riverway pollution remediation method

PendingCN112209505APromote degradationAchieve degradationWater contaminantsTreatment with aerobic and anaerobic processesMicroorganismEnvironmental engineering

The invention discloses a zeolite immobilized microorganism and plant combined riverway pollution remediation method which comprises the following steps: A, a pretreatment stage, B, a biological treatment stage, C, a plant treatment stage and D, a later optimization stage, zeolite is used as a carrier, so that the problem of immobilization of microorganisms in water pollution remediation is solved; zeolite serves as a carrier and can provide attachment points for microorganisms, the hydraulic retention time of the microorganisms in the water body is prolonged, the treatment efficiency of the microorganisms is improved, through the synergistic effect of zeolite immobilized microorganisms and plants, the levels of COD, nitrogen, phosphorus and metal salt in the water body are reduced, the physical and chemical environment of the water body is improved, the growth of algae is controlled through the competitive relationship, and the long-term treatment effect is achieved.

Owner:南京师盛生态环境研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com