Imidazole aldehyde waste water treatment process and operating method thereof

A technology of wastewater treatment and operation method, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control and other directions, can solve problems such as poor treatment effect, and achieve the effect of recycling resources and preventing poor treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

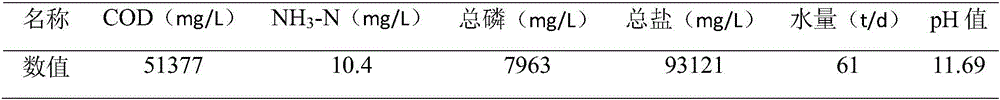

[0034] The basic properties of imidazole aldehyde wastewater produced in the first production workshop of a pesticide factory in a chemical industry park in Jiangxi are shown in Table 1. The wastewater is high-salt, high-COD, and high-phosphorus wastewater.

[0035] Table 1 Basic properties of imidazole aldehyde wastewater

[0036]

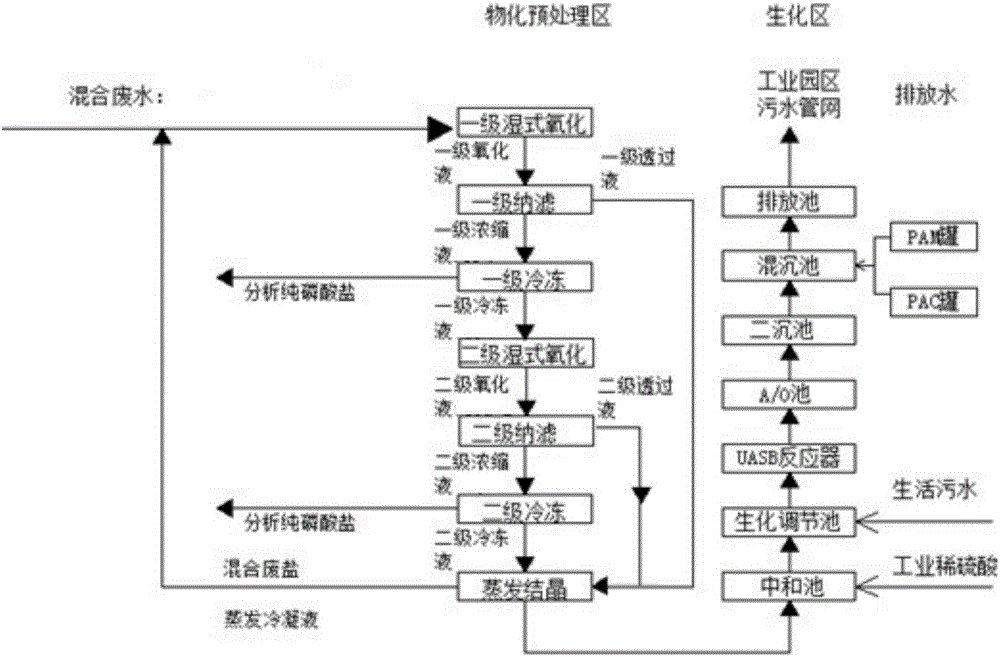

[0037] The specific process flow of wastewater treatment adopted by the sewage station is as follows ( figure 1 ):

[0038]The sewage physical and chemical pretreatment area includes: primary wet oxidation 1, primary nanofiltration 2, primary freezing 3, secondary wet oxidation 4, secondary nanofiltration 5, secondary freezing 6, and evaporation crystallization 7. The sewage biochemical area includes: pH neutralization tank 8, biochemical adjustment tank 9, UASB reactor 10, A / O tank 11, secondary sedimentation tank 12, mixed sedimentation tank 13, and discharge tank 14. High-salt, high-COD, high-phosphorus imidazole aldehyde wastewater passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com