Method and system for recycling struvite from sludge

A struvite and sludge technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of insufficient release and extraction of phosphorus, waste of phosphorus resources, etc., to achieve The effect of reducing sludge, increasing phosphorus content, and reducing the difficulty of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

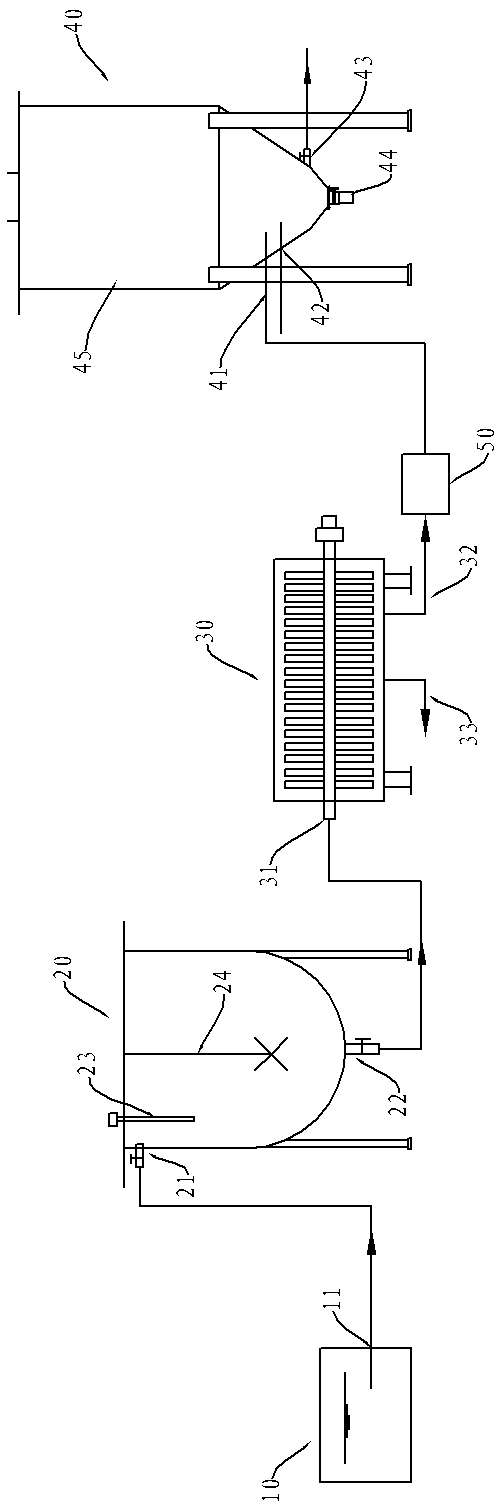

[0044] The thickened sludge with a water content of 97% in the sludge thickening tank 10 is pumped into the ultrasonic reaction tank 20 by the feed port 21 through the discharge port 11, and the ultrasonic generating device 23 and the stirring device 24 are opened to the ultrasonic reaction tank 20. The concentrated sludge is subjected to ultrasonic treatment, the ultrasonic power of the ultrasonic generating device 23 is set to 0.4W / mL, and the ultrasonic treatment time is 60 minutes;

[0045] The ultrasonically treated concentrated sludge is discharged from the ultrasonic reaction tank 20 from the discharge port 22 and pumped into the diaphragm plate frame filter press 30 through the feed port 31 for solid-liquid separation treatment, and the feed pressure is controlled to be 1.0Mpa. The feeding time is 1.5 hours, the pressing pressure is controlled at 1.6Mpa, and the pressing time is 1.0 hours. After the press filtration and dehydration treatment, the solid phase in the slud...

Embodiment 2

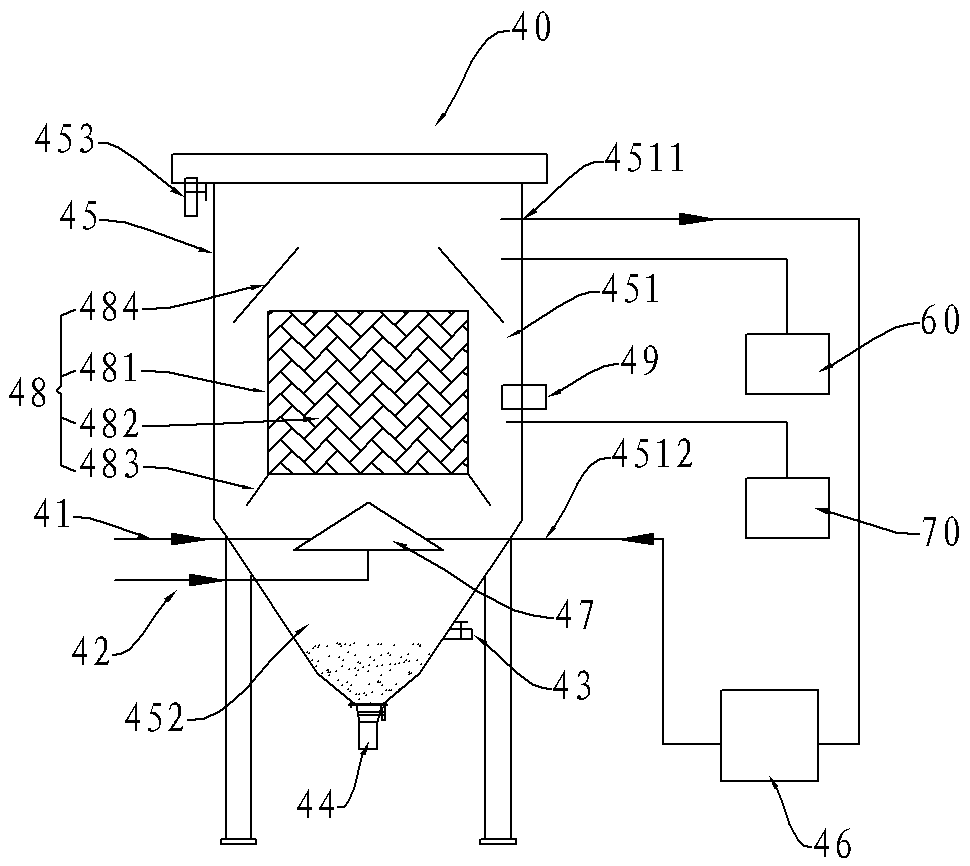

[0049] The difference between Embodiment 2 and Embodiment 1 is that the ultrasonic power of the ultrasonic generating device 23 is set to 0.2W / mL, the ultrasonic treatment time is 75 minutes, and the struvite is added in a ratio of Mg:P molar ratio of 1.5:1 during the recovery process of the struvite reaction. MgCl 2 And it is distributed into the stainless steel mesh 482 in the stainless steel reaction liner 481 through the liquid distributor 47 .

[0050] The difference between Embodiment 3 and Embodiment 1 and 2 is that the ultrasonic power of the ultrasonic generating device 23 is set to 0.5W / mL, the ultrasonic treatment time is 90 minutes, and the molar ratio of Mg:P is 1.3:1 during the struvite reaction recovery process. Add MgCl 2 And it is distributed into the stainless steel mesh 482 in the stainless steel reaction liner 481 through the liquid distributor 47 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com