Round subsider micro-filter cloth surface filtration water exit method

A technology of surface filtration and microfiltration cloth, which is applied in the direction of fixed filter element filter, filtration separation, separation method, etc. It can solve the problem that the concentration of suspended solids is difficult to meet this requirement, and achieve easy maintenance, small loss of filtration head, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

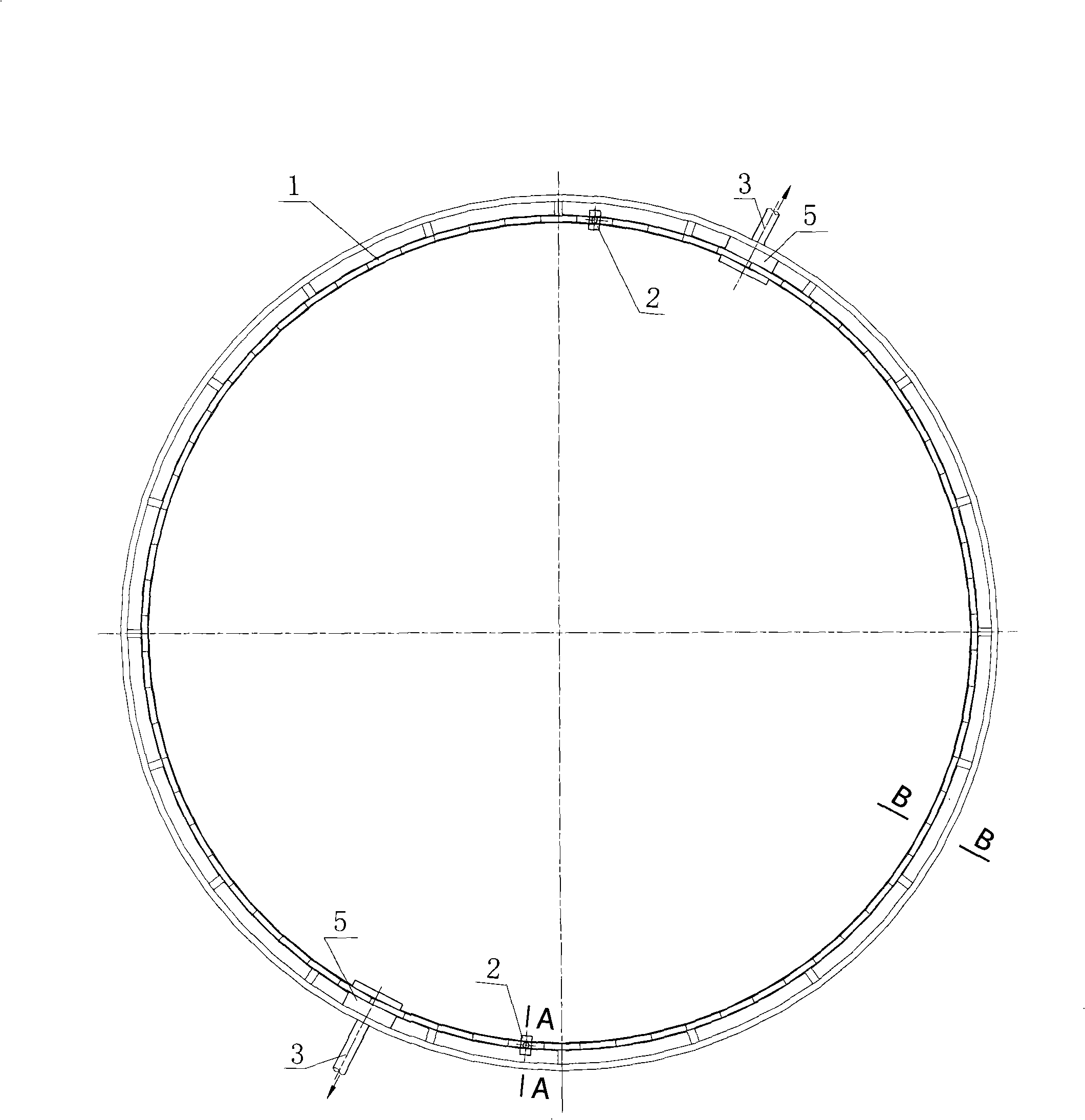

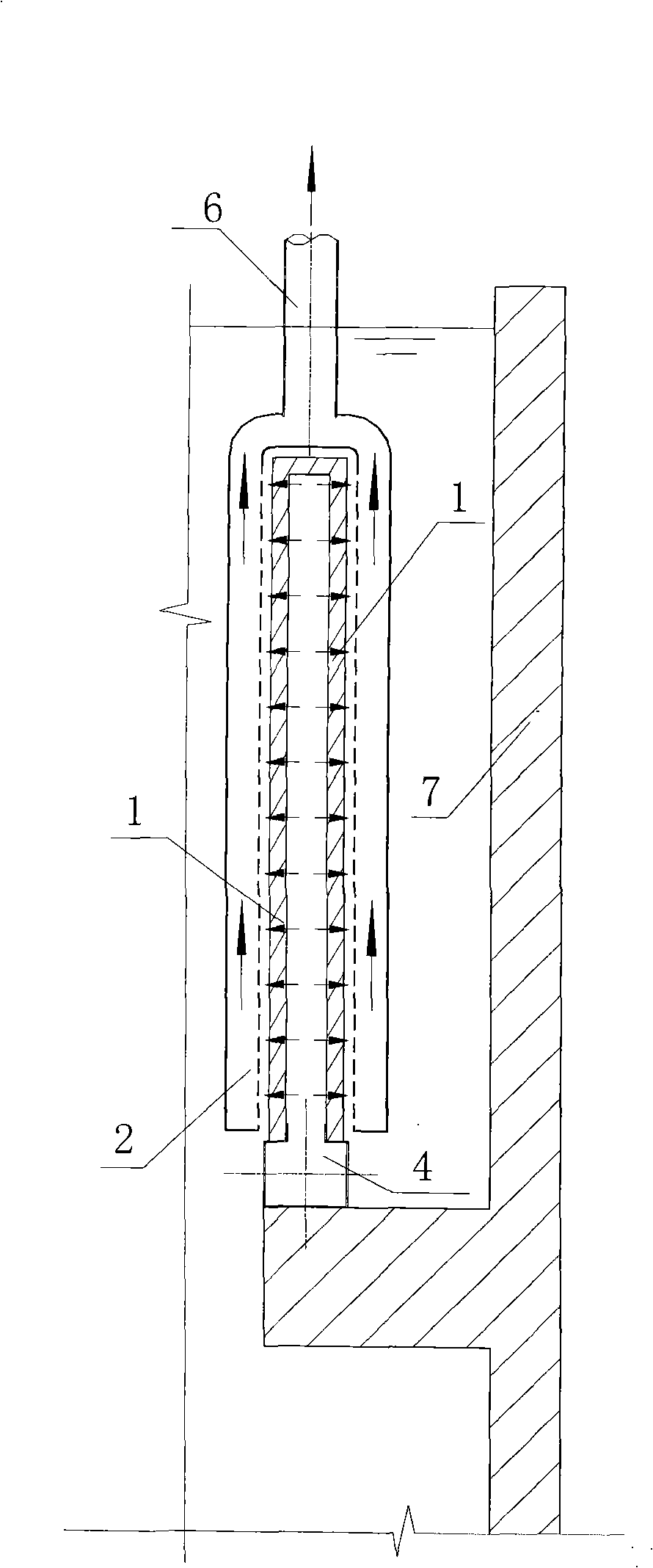

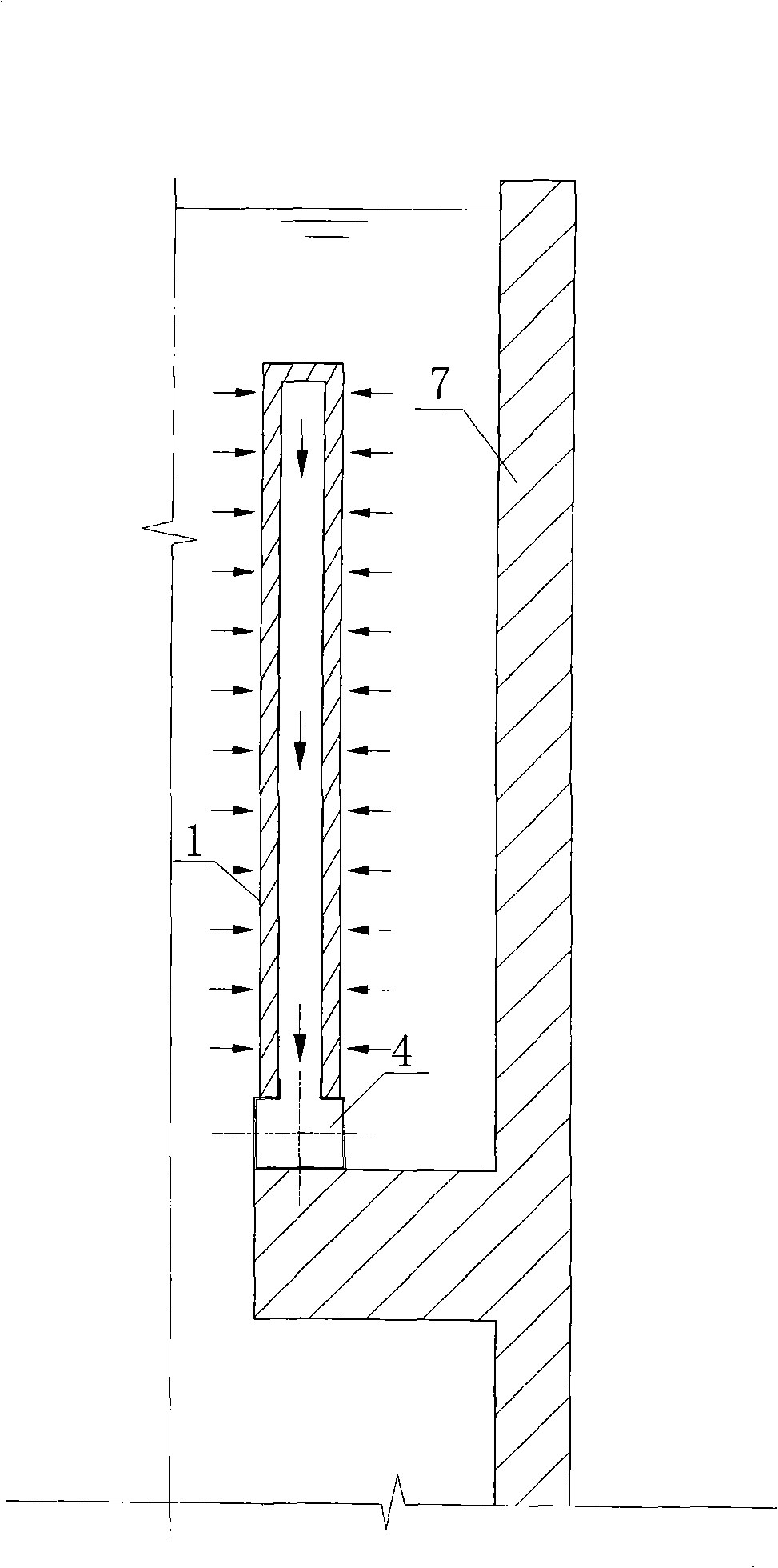

[0019] The method for filtering water out of the surface of the circular sedimentation tank microfiltration cloth provided by the invention is: see figure 1 , it uses a filter water outlet system mainly composed of a microfiltration cloth filter plate 1, an automatic cleaning device 2 and a backwash water pump connected to it through a backwash pipeline 6, instead of the outlet weir outlet method of the usual sedimentation tank to achieve water outlet. Among them: there are multiple microfiltration cloth filter plates arranged along the periphery of the circular sedimentation tank. They perform surface filtration on the sewage in the circular sedimentation tank to make the concentration of suspended solids in the sewage lower than 10mg / L; When the filter plate is clogged, the automatic cleaning device will backwash the micro filter cloth filter plate to restore the filtration function of the micro filter cloth filter plate.

[0020] The method for filtering water out of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com