Carbon-based adsorbent for removing phosphate in solution

A carbon-based adsorbent and phosphate technology, applied in the direction of adsorption of water/sewage treatment, application, matrix fertilizer, etc., can solve the problems of secondary pollution, high cost, high product treatment cost, etc., to alleviate water pollution and reduce phosphorus effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

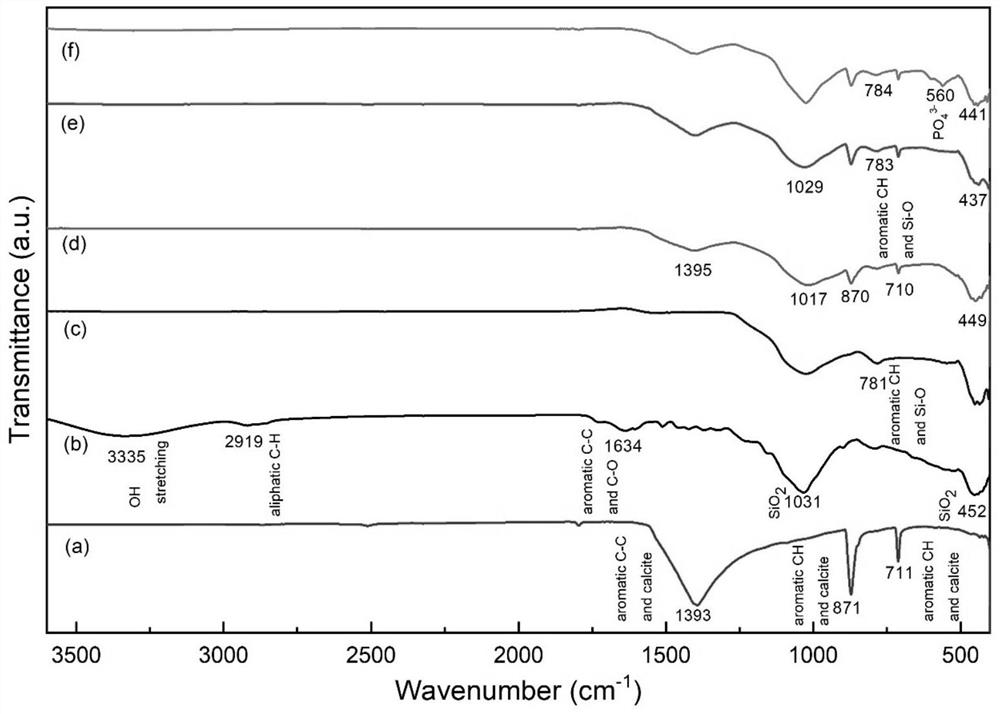

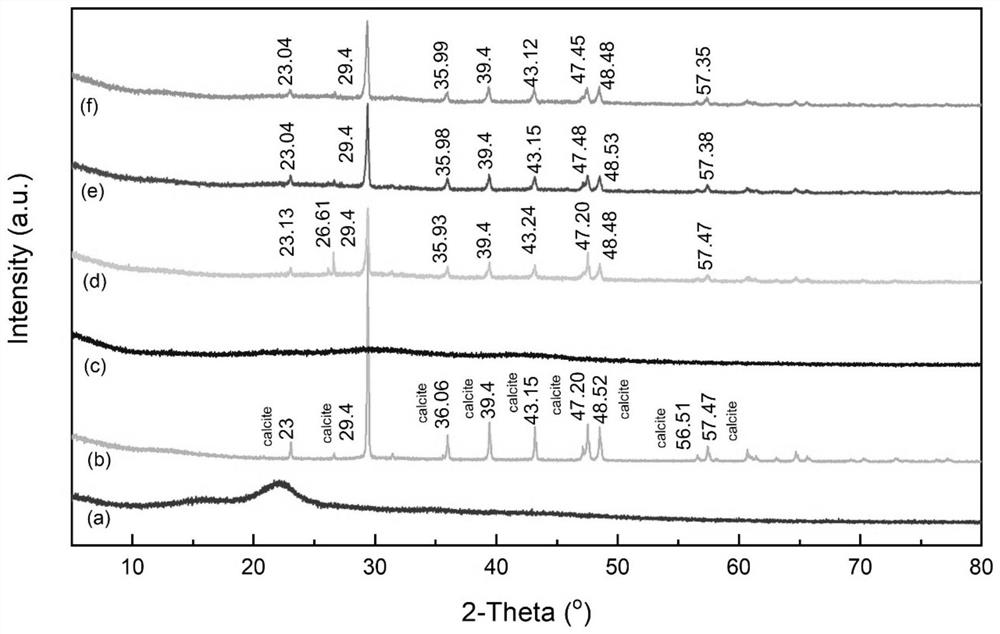

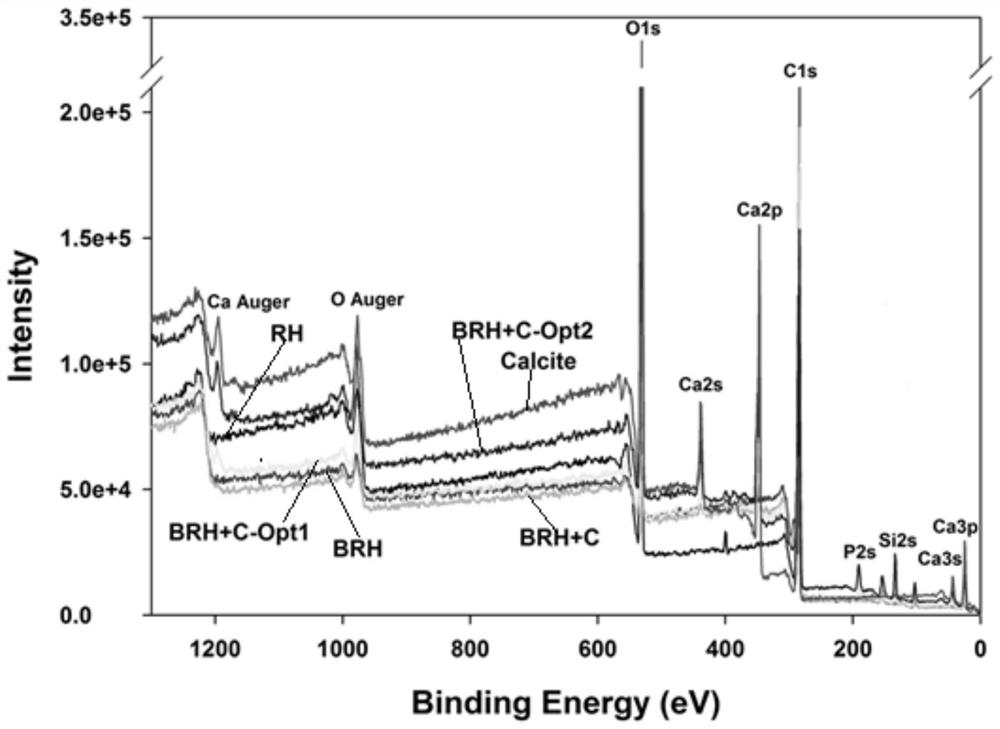

[0032] A carbon-based adsorbent for removing phosphate in water, prepared by the following method:

[0033] (1) After mixing the biomass raw material (rice husk) and calcite according to the weight ratio of 1:1, send it into the carbonization furnace for carbonization. The conditions of carbonization treatment are temperature 500 ° C, time 3 hours, and pulverization to 80-150 mesh Calcite-modified biochar was obtained.

[0034] (2) Carry out dilute alkali treatment to the calcite-modified biochar, then wash with deionized water for 3 times, and centrifuge to dry to obtain the primary carbon-based adsorbent; the dilute alkali treatment is to immerse the calcite-modified biochar in dilute lye , heated to 35° C., and stirred at 50 rpm for 2 hours; the composition of the dilute lye is: 5% sodium hydroxide, 15% sodium carbonate, and the balance of water.

[0035](3) Put 1kg of agar, 0.5kg of starch and 1kg of primary carbon-based adsorbent into 40L of deionized water, ultrasonical...

Embodiment 2

[0037] A carbon-based adsorbent for removing phosphate in water, prepared by the following method:

[0038] (1) After mixing the biomass raw material (moso bamboo) and calcite according to the weight ratio of 5:1, send them into the carbonization furnace for carbonization. The conditions for carbonization treatment are 700°C for 2 hours, and pulverize to 80-150 mesh. Calcite modified biochar.

[0039] (2) Carry out dilute alkali treatment to the calcite-modified biochar, then wash with deionized water for 5 times, and centrifuge to dry to obtain the primary carbon-based adsorbent; the dilute alkali treatment is to immerse the calcite-modified biochar in dilute lye , heated to 45° C., and stirred at 80 rpm for 1 hour; the composition of the dilute lye is: 10% sodium hydroxide, 10% sodium carbonate, and the balance of water.

[0040] (3) Put 1kg of agar, 1kg of starch and 3kg of primary carbon-based adsorbent into 60L of deionized water, ultrasonically disperse for 30 minutes, ...

Embodiment 3

[0042] A carbon-based adsorbent for removing phosphate in water, prepared by the following method:

[0043] (1) After mixing the biomass raw material (hickory shell) and calcite according to the weight ratio of 4.2:1, send them into the carbonization furnace for carbonization. The conditions for carbonization treatment are temperature 600 ° C, time 2.5 hours, and pulverization to 80-150 Calcite-modified biochar was obtained.

[0044] (2) Carry out dilute alkali treatment to the calcite-modified biochar, then wash with deionized water 4 times, and centrifuge to dry to obtain the primary carbon-based adsorbent; the dilute alkali treatment is to immerse the calcite-modified biochar in dilute lye , heated to 40° C., and stirred at 60 rpm for 1.5 hours; the composition of the dilute lye is: 8% sodium hydroxide, 12% sodium carbonate, and the balance of water.

[0045] (3) Put 1kg of agar, 0.8kg of starch and 2kg of primary carbon-based adsorbent into 50L of deionized water, ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com