Laser processing method and corresponding laser machining apparatus

A laser processing method and laser processing technology, applied in the TFT field, can solve problems such as cracking and reducing the bending strength of glass materials, and achieve the effects of improving temperature differences, avoiding micro cracks, and reducing thermal expansion differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] Please refer to FIG. 1 , a laser processing method provided by an embodiment of the present invention. The laser processing method comprises the following steps:

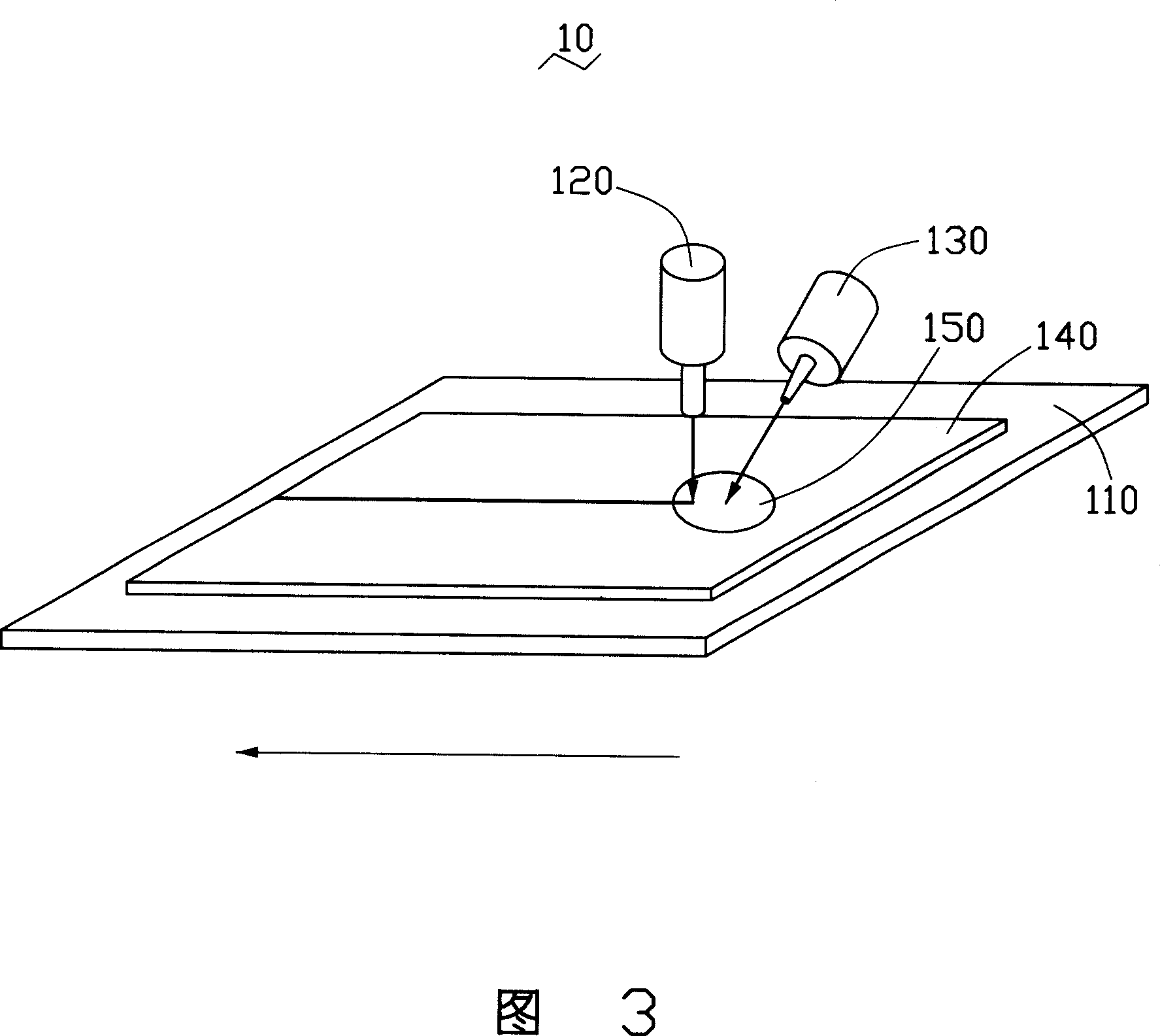

[0020] Step 1: Provide a processed object 140 and place the processed object 140 on a processing table 110 .

[0021] The processed object 140 is a brittle material, such as glass, silica or ceramics. The outer shape of the processed object 140 is preferably plate-like.

[0022] The processing table 110 is used to carry the processed object 140, which can be made of metal and other materials.

[0023] Step 2: heating the pre-processing area 150 of the processed object 140 to a predetermined temperature.

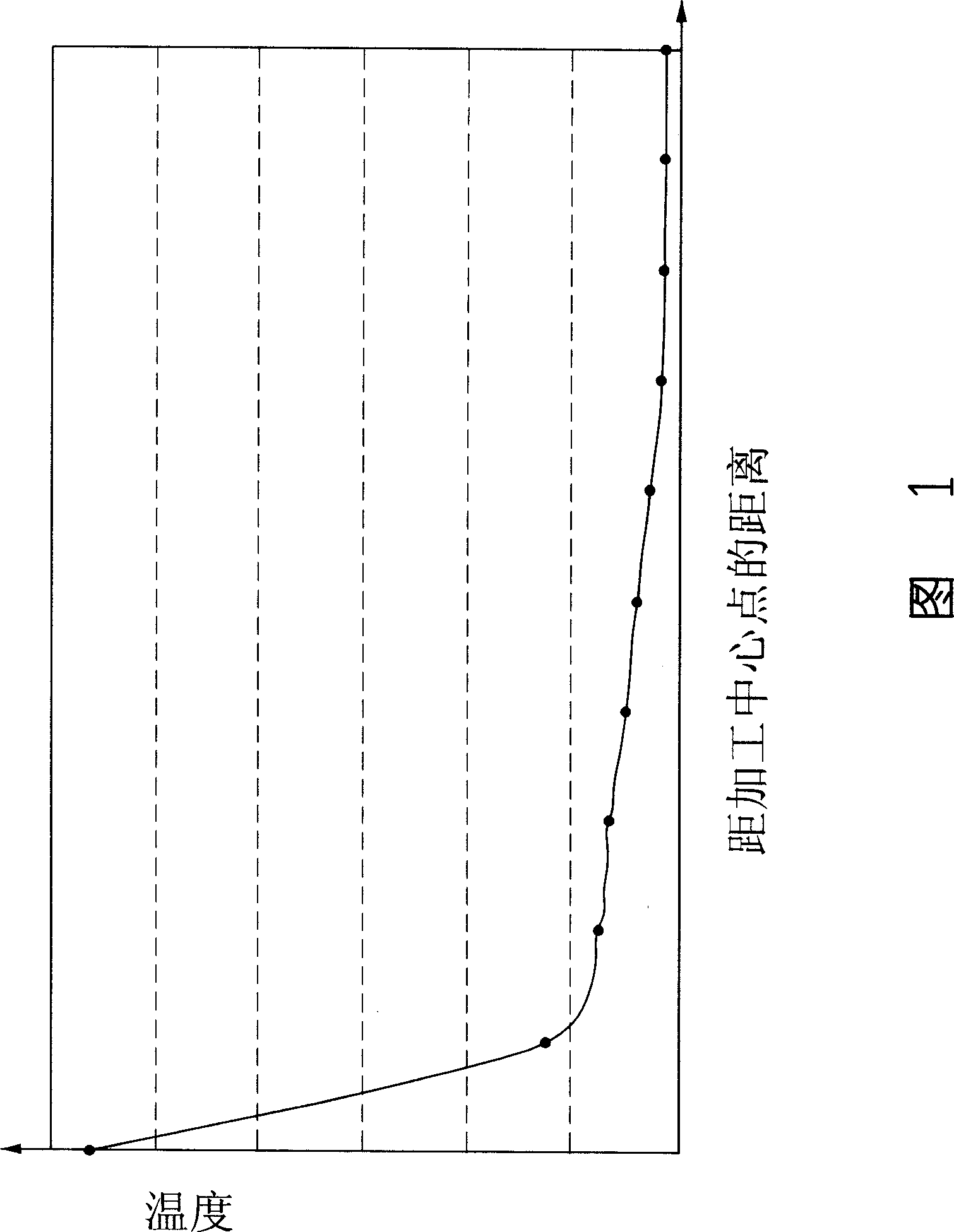

[0024] A heating source 130 is used to heat the pre-processing area 150 of the workpiece 140 to form a temperature field in the pre-processing area 150 and its vicinity. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com