Single-module independent water-cooled type automobile tail gas thermoelectric conversion device and method

A thermoelectric conversion device and thermoelectric conversion technology, which are applied to exhaust devices, mufflers, electrical components, etc., can solve problems such as low economic benefits, insignificant comprehensive benefits of automobile energy saving and emission reduction, and environmental aggravation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

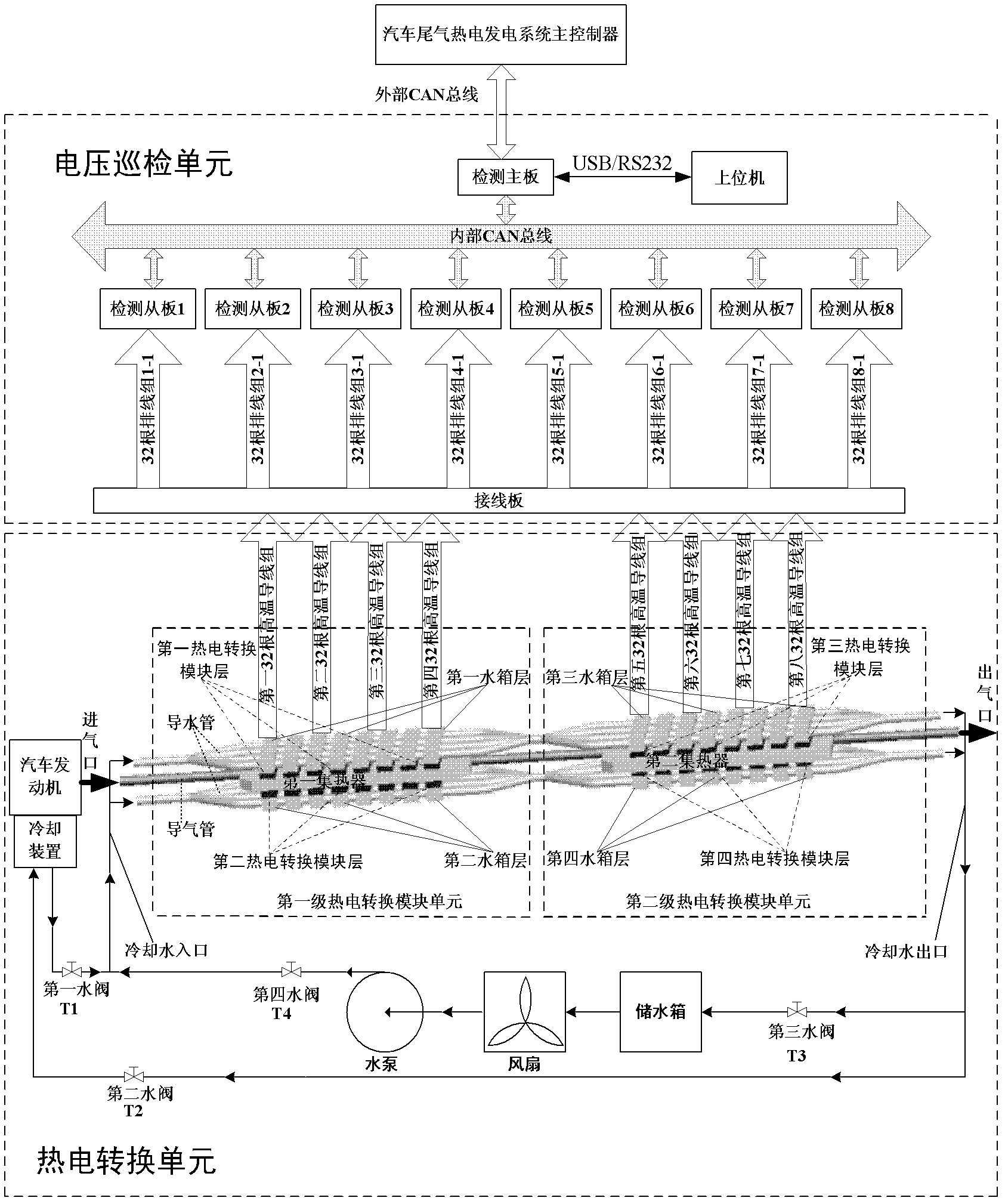

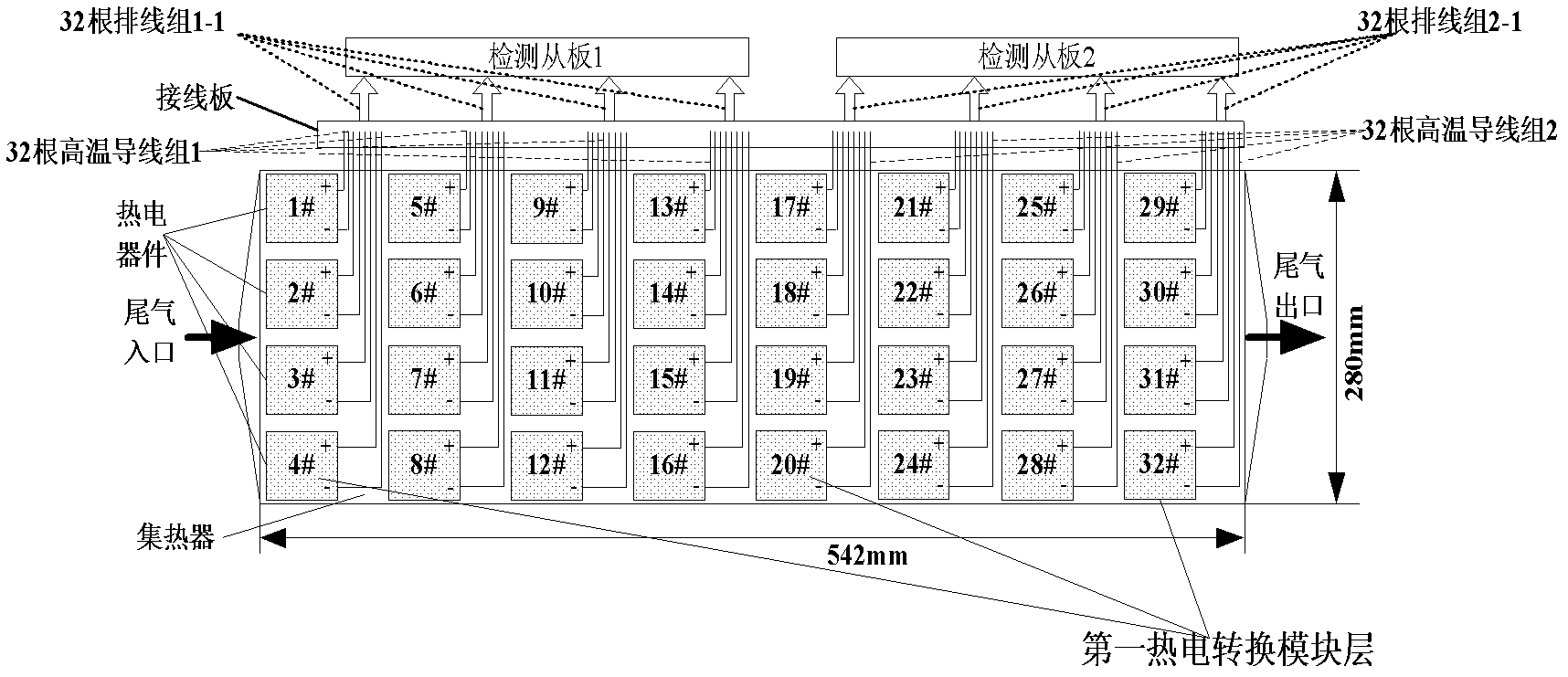

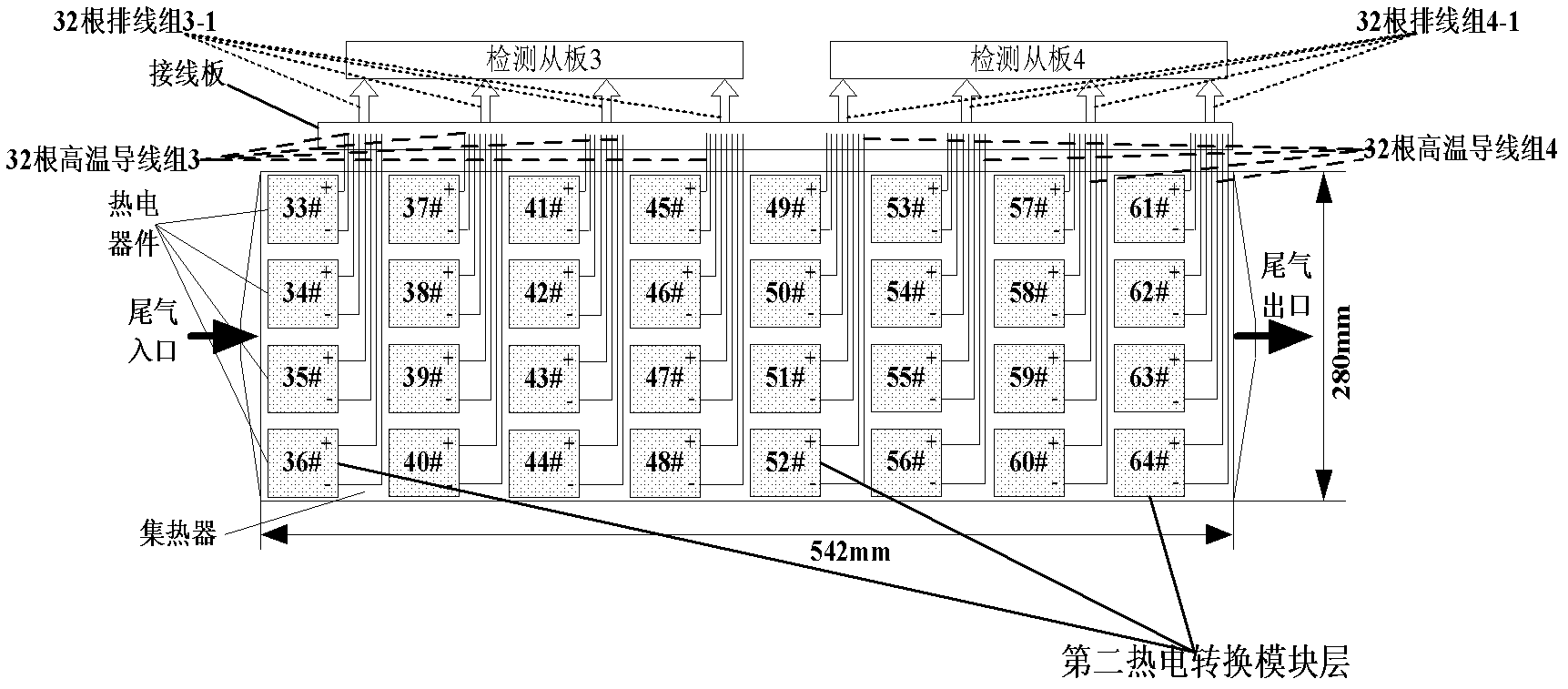

[0025] The main part of the present invention includes a thermoelectric conversion unit and a voltage detection unit (such as figure 1shown), wherein: the high-temperature exhaust gas discharged from the engine transfers heat to the hot end of the thermoelectric conversion module in the thermoelectric conversion unit through the exhaust pipe and the heat collector, and the cooling water in the engine cooling device or an externally independently designed cooling water circuit The temperature of the cold end of the thermoelectric conversion module in the thermoelectric conversion unit is controlled through the water tank layer; the thermoelectric conversion unit includes a first-level thermoelectric conversion module unit and a second-level thermoelectric conversion module un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com