Solar high-temperature vacuum heat-collecting tube

A vacuum heat collecting tube and solar energy technology, which is applied in the field of high temperature vacuum heat collecting tubes and vacuum heat collectors, can solve the problems of high production cost and complex structure of the heat insulation chamber, and achieve the effects of low production cost, simple structure and improved thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

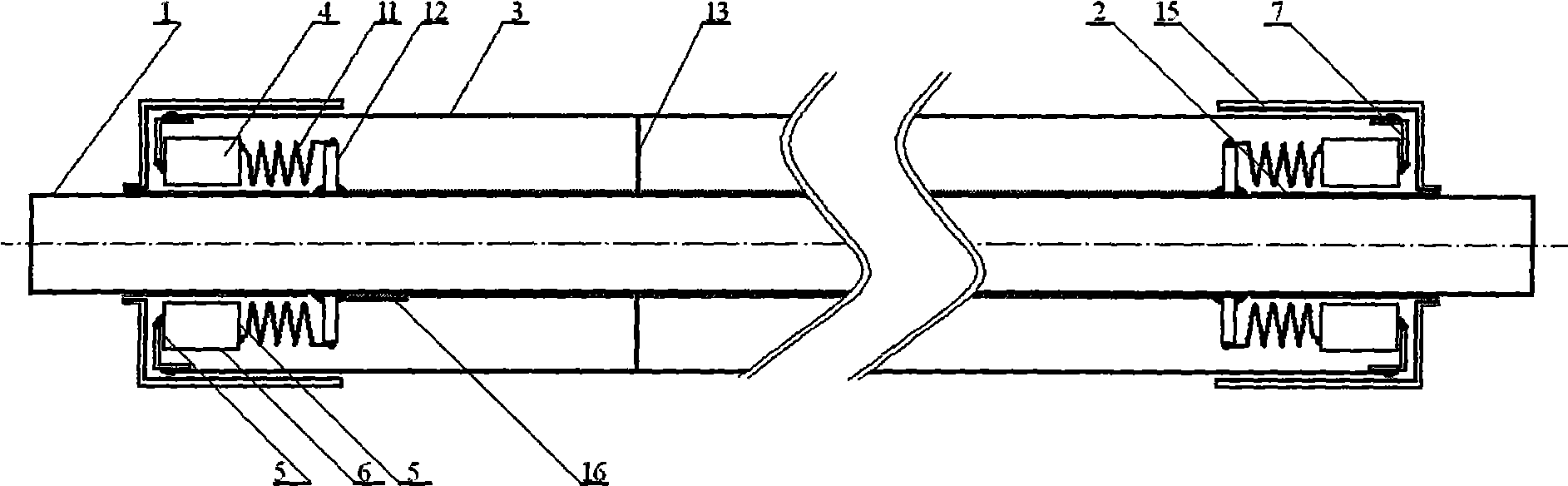

[0034] Such as figure 1 , figure 2 As shown, the high-temperature vacuum-type heat collector provided in this embodiment is mainly composed of a metal inner tube 1, a glass outer tube 3, a ceramic insulation ring 4, a Kovar ring 7, a metal bellows 11, a transition connection plate 12 and a protective end cap 15 poses.

[0035]The metal inner tube 1 is a stainless steel tube coaxially sheathed in the glass outer tube 3, and the outer surface of the steel tube is covered with a black body absorbing coating material which is selective to solar energy. The glass outer tube 3 is made of high boron glass, its inner wall is plated with an anti-reflection film, and the outer wall is plated with an anti-reflection protective film. The glass outer tube 3 and the metal inner tube 1 are hermetically connected, and the interlayer is vacuum. The outer surface of the stainless steel tube 1 in the interlayer is also spot-welded with a vacuum color display band 16 that can absorb air, whic...

Embodiment 2

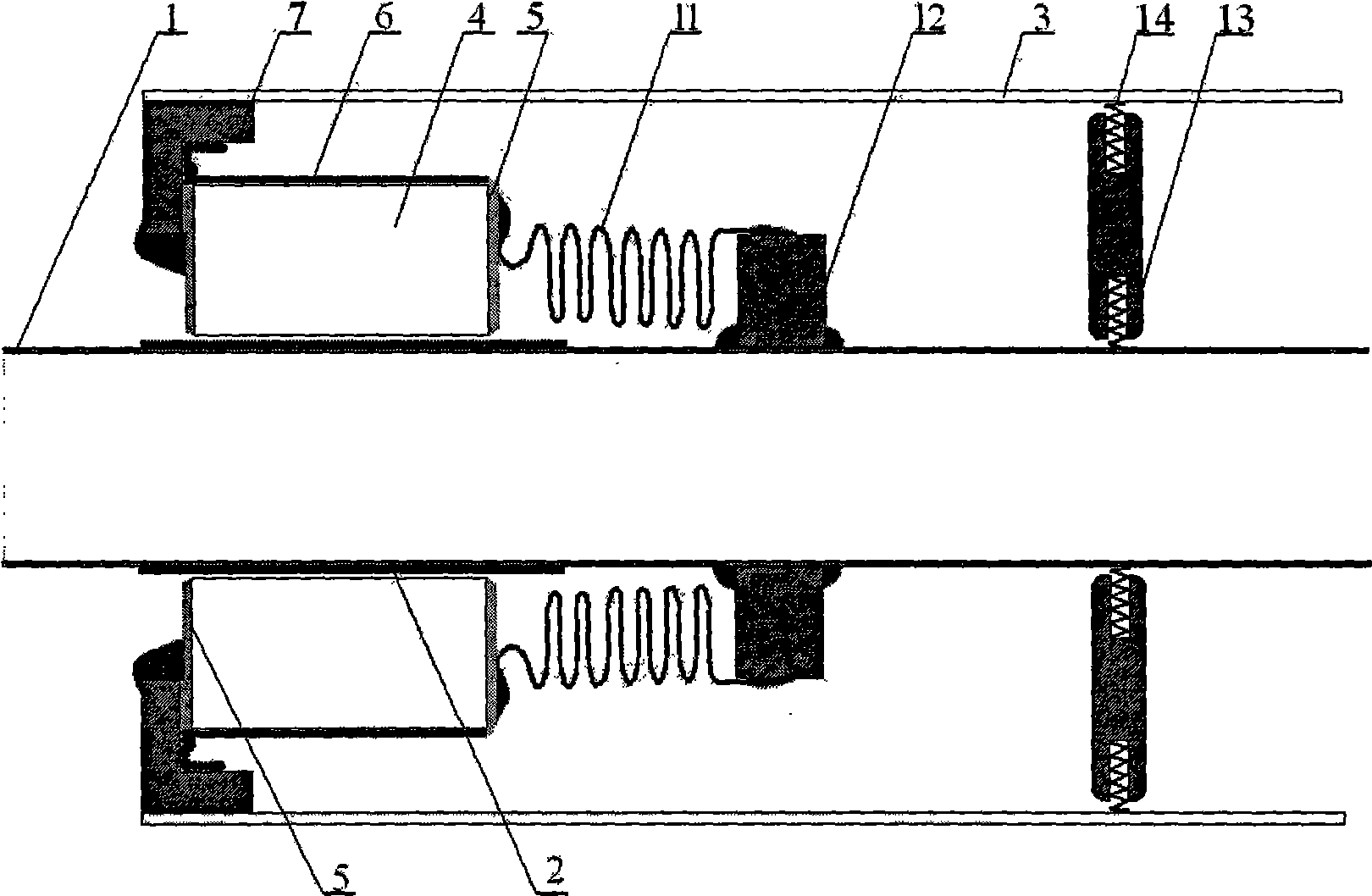

[0039] like image 3 As shown, the high-temperature vacuum type heat collector provided in this embodiment is also mainly composed of a metal inner tube 1, a glass outer tube 3, a ceramic insulation ring 4, Kovar alloy rings 7-8, a metal bellows 11, a transition connection plate 12 and Protective end cap 15 constitutes.

[0040] Due to the structure and production materials of the metal inner tube 1, the glass outer tube 3, the ceramic heat insulating ring 4, the Kovar ring 7, the metal bellows 11, the transition connection plate 12 and the protective end cap 15 of the present embodiment, including the The supporting ring 13 etc. are all the same as in Embodiment 1, so they are omitted. The difference is that a Kovar alloy ring 8 is added between the heat insulating ceramic ring 4 and the metal bellows 11 . The cross section of the Kovar ring 8 is "π"-shaped, and its "π"-shaped upper end surface is welded to the ceramic heat insulating ring 4, and its lower outer surface is ...

Embodiment 3

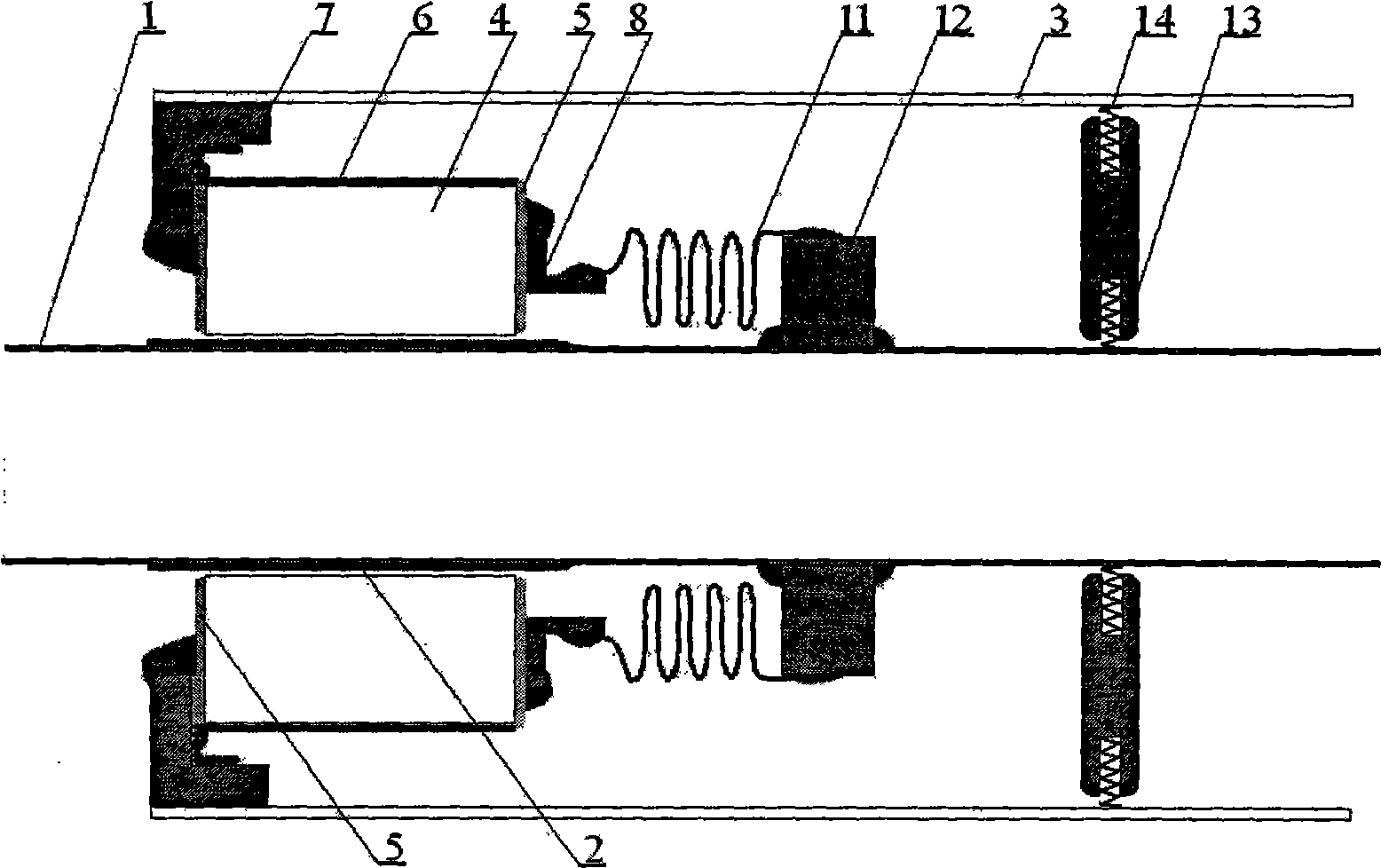

[0043] As shown in 4, the high-temperature vacuum heat collector provided in this embodiment is also mainly composed of a metal inner tube 1, a glass outer tube 3, a ceramic insulation ring 4, a Kovar alloy ring 9-10, a metal bellows 11, and a transition connection plate 12 and protective end cap 15 constitute.

[0044] Due to the structure and manufacturing materials of the metal inner tube 1, the glass outer tube 3, the ceramic insulation ring 4, the metal bellows 11, the transition land 12 and the protective end cap 15 of the present embodiment, including the supporting ring 13 provided therein, etc. Same as Example 1, so it is omitted. The difference is: ① In this embodiment, a Kovar alloy ring 10 is added between the heat insulating ceramic ring 4 and the metal bellows 11; ② The cross-sectional shape of the Kovar alloy ring 9 connected to the glass outer tube 3 is that On the basis of the concave shape, there is a protrusion extending from the end of the inner ring surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com