Bean gluten machine

A bean gluten machine and material layer technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of long time to complete film rolls, high labor intensity, and high cost, so as to reduce heat loss and prevent soybean milk Good effect of outflow and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

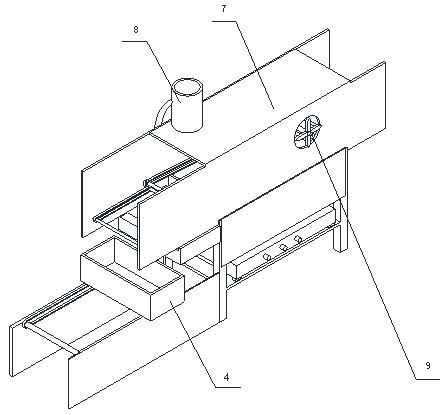

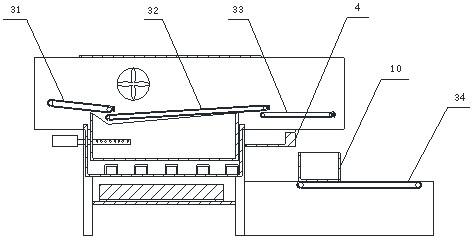

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a bean tendon machine includes a heating container, a heating device is provided below the heating container, and also includes a shaping roller 6 and a cover 7.

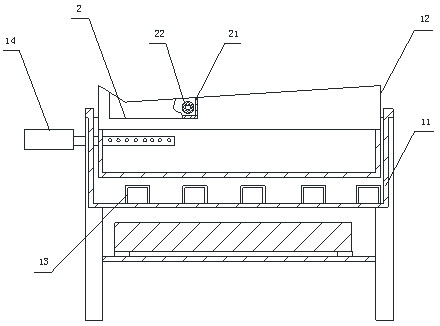

[0030] The heating vessel has a double-layer structure, wherein the outer layer is a heat-conducting layer 11, the inner layer is a material layer 12 with openings, and the heat-conducting layer 11 is provided with a metal-shaped secondary heater 13. The two opposite sides of the material layer 12 are V-shaped, and the two opposite sides are consistent with the feeding and discharging directions. The edge of the material layer 12 is provided with an overflow prevention device 2, and the material layer 12 is provided with convenient materials Circulating heating water pump 14, the air pipe of the water pump 14 communicates with the material layer 12, and a set of through holes is provided on the air pipe;

[0031] Above the material layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com