Inside heated FBG sensor and packaging method thereof

A packaging method and sensor technology, which are applied in the direction of converting sensor output, using optical devices to transmit sensing components, instruments, etc., can solve the problem that the accuracy of monitoring results is not well guaranteed, the sensitivity of temperature and strain factors, and the influence of FBG temperature monitoring. and other problems, to achieve the effects of excellent thermal stability and thermal conductivity, simple layout and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

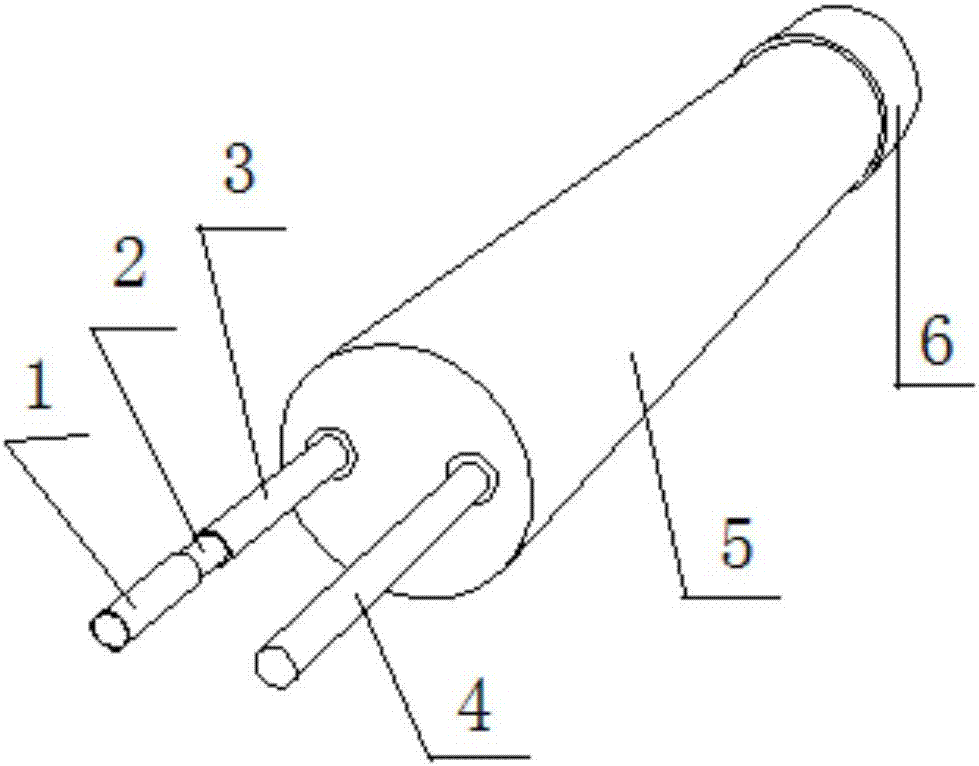

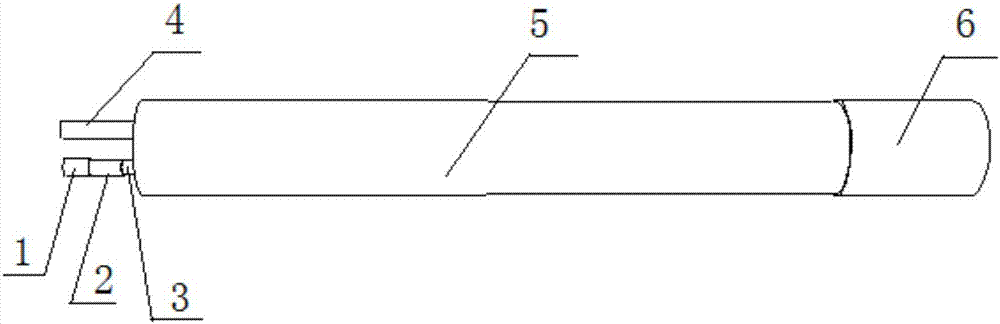

[0024] Such as Figure 1-2 As shown, in the embodiment, a double-hole corundum tube with a length of 10 cm, a diameter of 4 mm, a hole diameter of 1 mm, and a hole distance of 1 mm is taken as an example for illustration.

[0025] An internal heating FBG sensor, comprising a corundum tube body 5, an optical fiber lead wire 2, a heating resistance wire 4 and an FBG sensor 3, two holes are arranged on the corundum tube body 5, and an optical fiber lead wire 2 is provided at both ends of the FBG sensor 3 and The FBG sensor 3 is arranged in one of the holes, and the heating resistance wire 4 is arranged in the other hole. The other end of the optical fiber lead 2 is wrapped with a lead sheath 1 to protect the FBG sensor 3 . Both ends of the corundum tube body 5 are provided with heat-shrinkable tubes 6 . Used to prevent leakage and waterproof.

[0026] Wherein, both channels are cylindrical channels.

[0027] The packaging method of the internal heating FBG sensor in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com