In-bed heat transfer tube for fluidized bed boiler

A technology for fluidized bed boilers and heat transfer tubes, applied to boiler water tubes, components of steam boilers, steam boilers, etc., can solve the problems of reduced heat transfer rate, poor durability, thicker diameter, etc., and achieve the suppression of tube wall thinning , Excellent durability, and the effect of improving heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

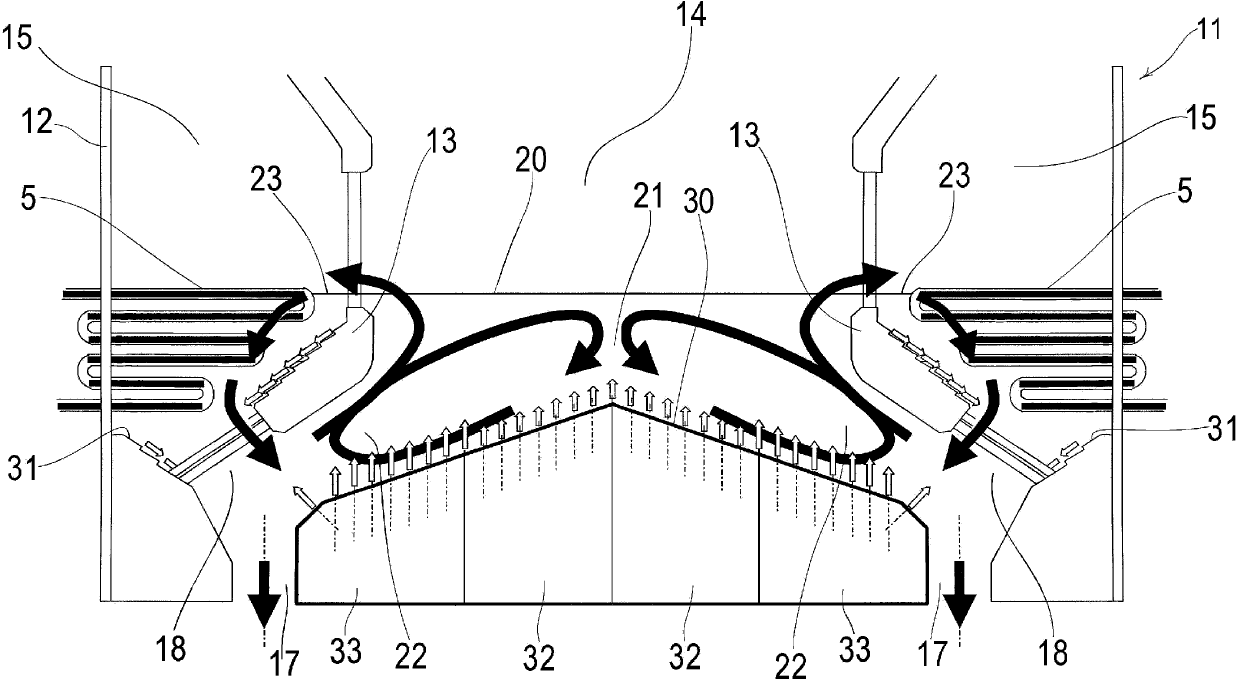

[0054] Below, refer to figure 1 Referring to FIG. 8, an embodiment of the heat transfer tube in the fluidized bed boiler of the present invention will be described. exist figure 1 In FIG. 8 , the same reference numerals are assigned to the same or corresponding components, and overlapping descriptions will be omitted.

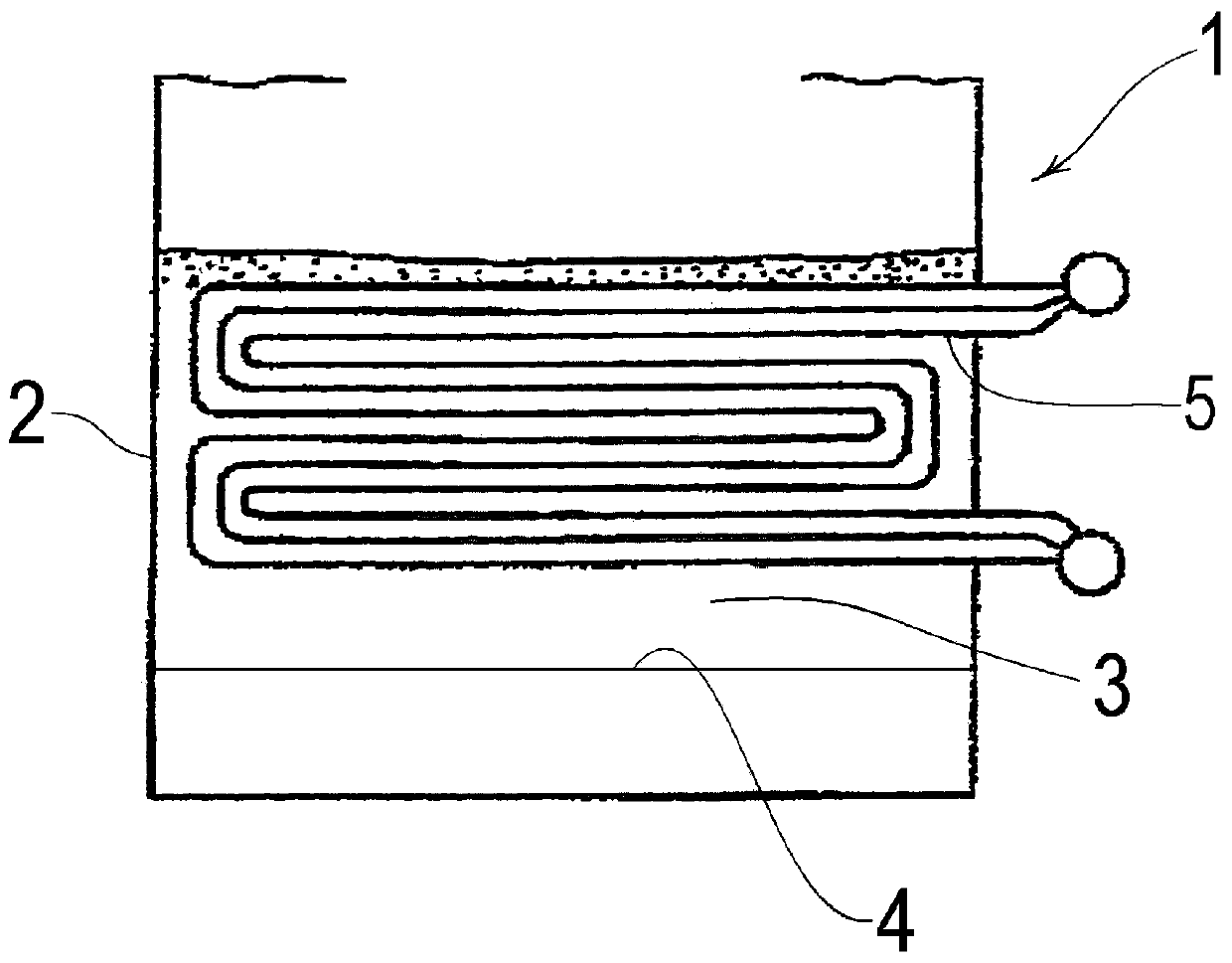

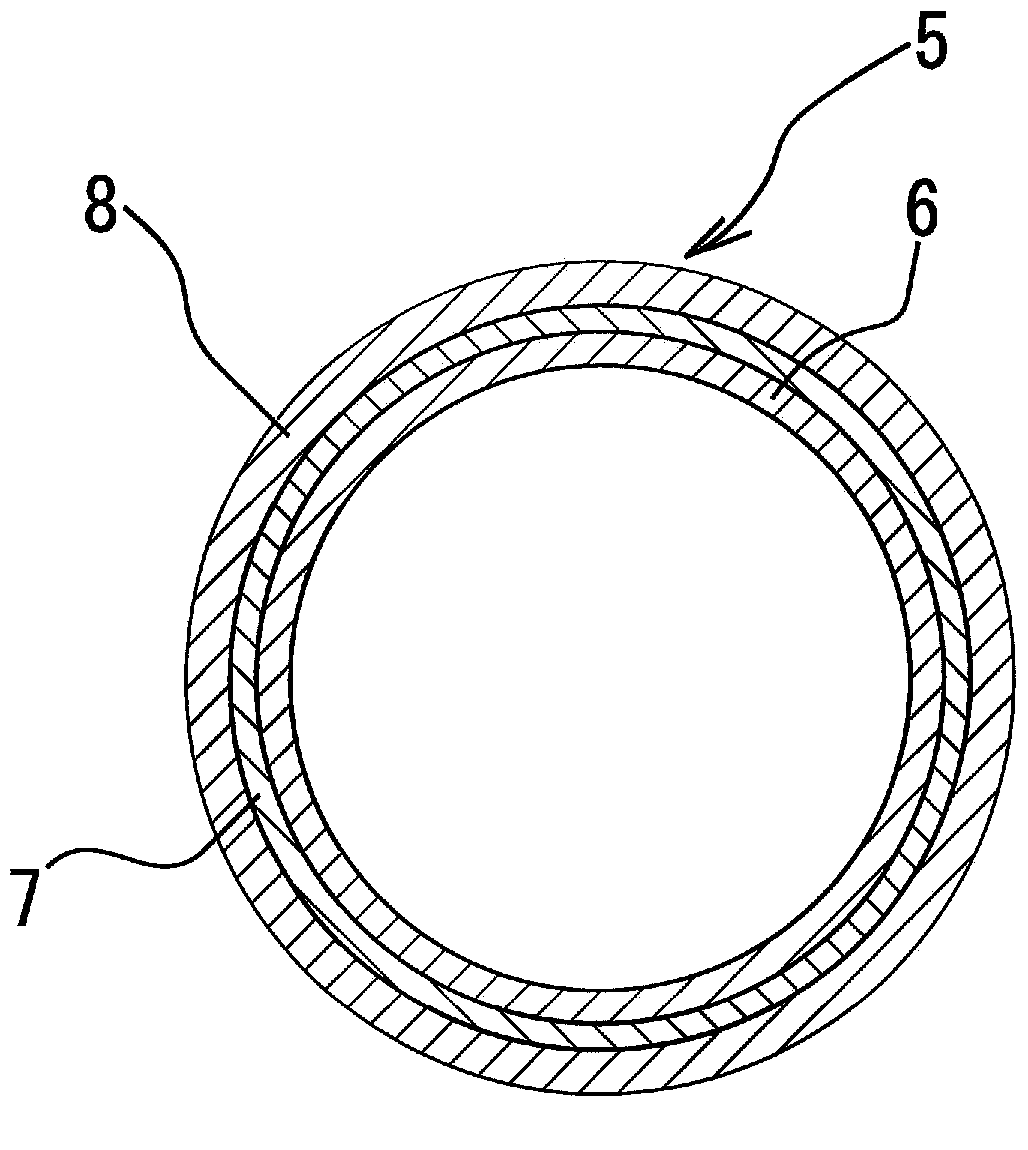

[0055] figure 1 It is a schematic cross-sectional view showing an embodiment of a fluidized-bed boiler provided with an intra-layer heat transfer tube of the present invention. Such as figure 1 As shown, a fluidized bed boiler 1 is provided with: a furnace body 2 having a substantially cylindrical shape or a substantially square cylindrical shape; a fluidized bed 3 for burning fuel such as waste or RDF; and a hearth floor 4 supporting the fluidized bed 3, and Layer 3 is provided with inner layer heat transfer pipes 5 . The fluidized bed 3 is filled with fluidized sand such as silica sand, that is, a fluidized medium, so as to bury the heat transfer tubes 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com