Mildew-proof and anti-bacterium liquid crystal electronic glass partition paper and production technology thereof

A glass spacer paper, anti-mildew and anti-bacteria technology, applied in the direction of anti-biological reagent addition, paper, paper making, etc., to achieve high mechanical strength, anti-mildew pollution, and low moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A mildew-proof and antibacterial liquid crystal electronic glass spacer paper, the slurry of the spacer paper includes 50% of the original softwood pulp, 30% of the original hardwood pulp and 20% of the coniferous wood pulp; wherein the softwood pulp and The coniferous wood pulp was mixed and beaten with a beating concentration of 4.0% and a beating degree of 30°SR; the hardwood pulp was beaten separately with a beating concentration of 3.5% and a beating degree of 25°SR.

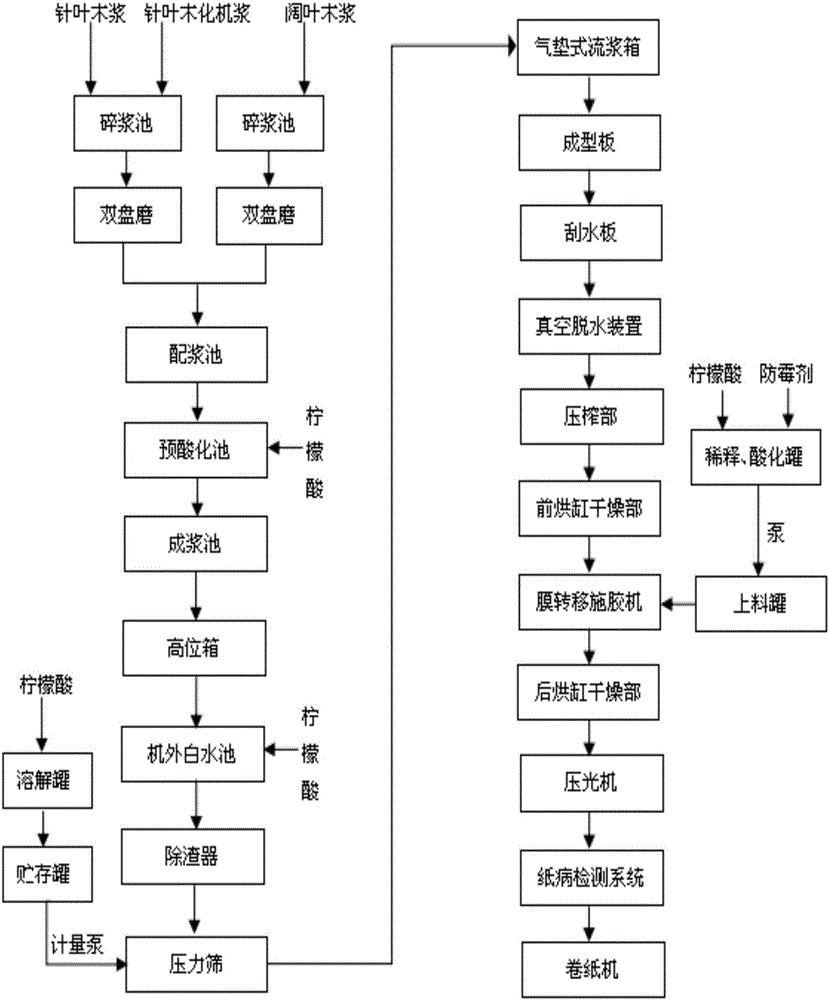

[0033] The production process of the aforementioned anti-mildew and antibacterial liquid crystal electronic glass spacer paper, such as figure 1 shown, including the following steps:

[0034] (1) Firstly, the coniferous wood pulp and the coniferous lignified mechanical pulp are mixed in proportion and then pulverized in a pulper, and the hardwood pulp is separately pulverized, and then beaten by double disc mills respectively;

[0035] (2) After mixing the pulp after beating, store it in the slurry ...

Embodiment 2

[0043] A mildew-proof and antibacterial liquid crystal electronic glass spacer paper, the slurry of the spacer paper includes 70% of the original softwood pulp, 10% of the original hardwood pulp and 20% of the coniferous wood pulp; wherein the softwood pulp and The coniferous wood pulp was mixed and beaten with a beating concentration of 6.0% and a beating degree of 25°SR; the hardwood pulp was beaten separately with a beating concentration of 4.5% and a beating degree of 20°SR.

[0044] The production process of the aforementioned anti-mildew and antibacterial liquid crystal electronic glass spacer paper comprises the following steps:

[0045] (1) first mix the coniferous wood pulp and the coniferous lignified mechanical pulp according to the proportion and then pulp in the pulper, and the hardwood pulp is separately pulped, and then be beaten by double disc mills respectively;

[0046](2) After mixing the pulp after beating, store it in the slurry mixing tank, then transfer ...

Embodiment 3

[0054] A mildew-proof and antibacterial liquid crystal electronic glass spacer paper, the slurry of the spacer paper includes 60% of the original softwood pulp, 30% of the original hardwood pulp and 10% of the coniferous wood pulp; wherein the softwood pulp and The coniferous wood pulp was mixed and beaten with a beating concentration of 5.0% and a beating degree of 28°SR; the hardwood pulp was beaten separately with a beating concentration of 4.0% and a beating degree of 22°SR.

[0055] The production process of the aforementioned anti-mildew and antibacterial liquid crystal electronic glass spacer paper comprises the following steps:

[0056] (1) first mix the coniferous wood pulp and the coniferous lignified mechanical pulp according to the proportion and then pulp in the pulper, and the hardwood pulp is separately pulped, and then be beaten by double disc mills respectively;

[0057] (2) Store the slurry after beating in the slurry mixing pool after being mixed, and then c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com