Waterborne fluorinated graphene coating and preparation method and application thereof

A fluorinated graphene and water-based fluorine technology, applied in the field of coatings, can solve the problems of reducing the protective ability of the guardrail, the loss of the zinc layer, and the decline of the appearance and decoration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

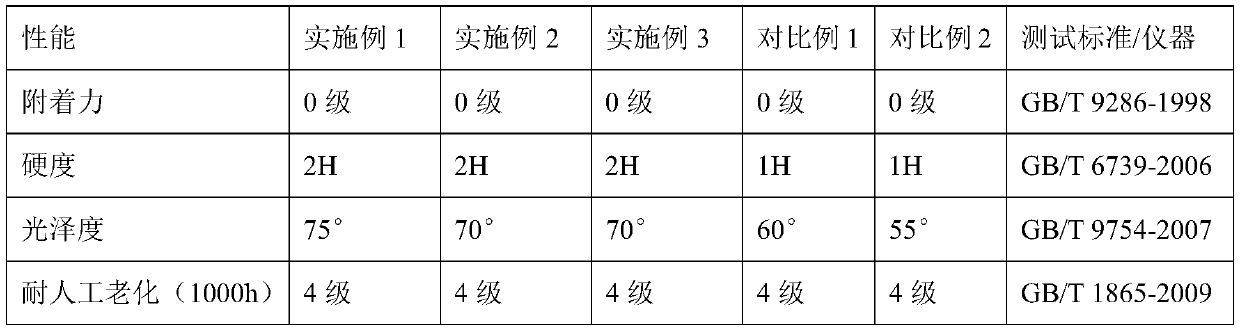

Examples

preparation example Construction

[0076] The preparation method of fluorine-modified acrylic acid emulsion is as follows:

[0077] S1: In a four-necked flask equipped with a stirring and reflux condenser, add 200 parts by mass of deionized water, 2 parts by mass of sodium lauryl sulfate and 2 parts by mass of OP-10 emulsifier, and stir for 30 minutes. An emulsifier solution is obtained.

[0078] S2: In a glass reactor, 17 parts by mass of perfluorooctylethyl methacrylate, 50 parts by mass of butyl methacrylate and 3 parts by mass of methacrylic acid were mixed uniformly, and the 100 parts obtained in S1 Parts by mass of the emulsifier solution was added into a glass reactor, stirred evenly, and ultrasonically emulsified for 1 hour to obtain a monomer pre-emulsion.

[0079] S3: 100 parts by mass of the emulsifier solution was heated up to 80° C., and 100 parts by mass of the monomer pre-emulsion and 2 parts by mass of an aqueous potassium persulfate solution (4 wt %) were added dropwise under nitrogen protecti...

Embodiment 1

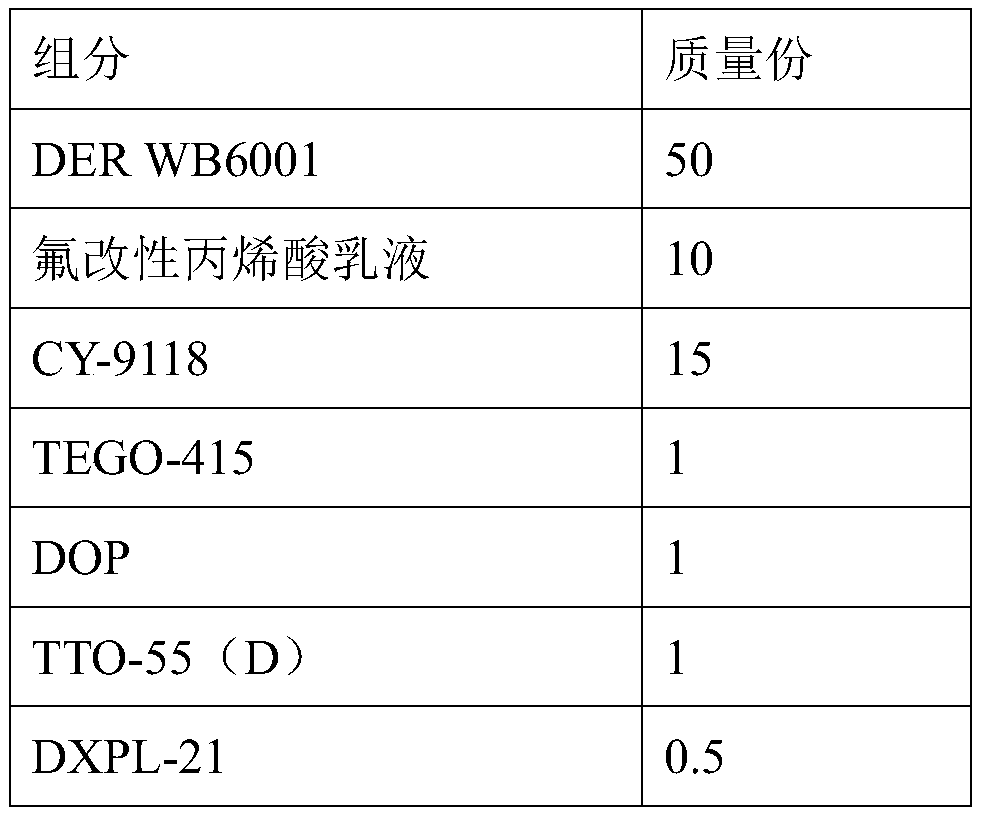

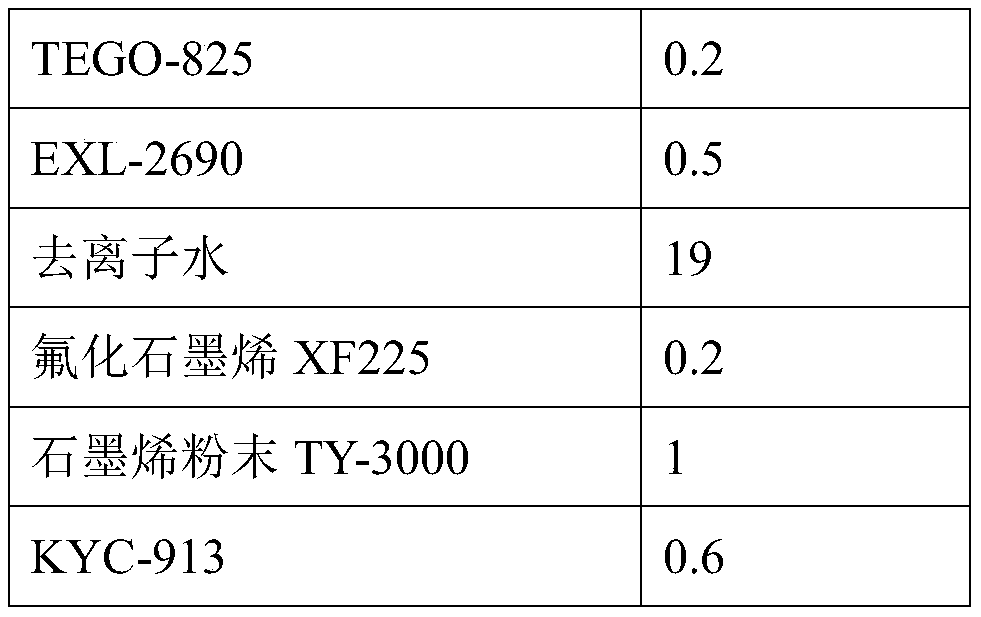

[0083] The composition of the coating A component of Example 1 is shown in Table 1.

[0084] The A component composition of table 1 embodiment 1 coating

[0085] components parts by mass DER WB6001 60 Fluorine modified acrylic emulsion 5 CY-9118 10 BYK-306 1 DOP 1 P25 1 DXPL-21 0.5 TEGO-825 0.2 EXL-2690 0.5 Deionized water 20.2 Fluorinated graphene XF225 0.05 Graphene powder TY-3000 0.25 KYC-913 0.3

[0086] The preparation method of the aqueous fluorinated graphene coating of embodiment 1 is as follows:

[0087] Add nano-dispersant KYC-913, fluorinated graphene powder, graphene powder, and deionized water into the glass reactor according to the ratio in Table 1, first stir at 900r / min for 1 hour, then ultrasonically disperse for 30 minutes, and ultrasonically The power is 1.5kW, and the graphene dispersion suspension is obtained after discharging.

[0088] Put the remaining materials...

Embodiment 2

[0092] The composition of the coating A component of Example 2 is shown in Table 2.

[0093] The A component composition of table 2 embodiment 2 coatings

[0094] components parts by mass DER WB6001 50 Fluorine modified acrylic emulsion 15 CY-9118 10 BYK-306 1 DOP 1 P25 1 DXPL-21 0.5 TEGO-825 0.2 EXL-2690 0.5 Deionized water 19.9 Fluorinated graphene XF225 0.1 Graphene powder TY-3000 0.5 KYV-913 0.3

[0095] The only difference between the water-based fluorinated graphene coating in Example 2 and the preparation method in Example 1 is that the materials are added according to the composition of A component in Table 2, and the rest of the preparation methods are the same.

[0096] The coating in this example uses curing agent WB8006 as component B, and the mass ratio of component A to component B is 100:20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com