A kind of water-based fluorinated graphene coating and preparation method and application thereof

A fluorinated graphene and water-based fluorine technology, applied in the field of coatings, can solve the problems of loss of anti-corrosion ability, decreased appearance and decoration, loss of zinc layer, etc. The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

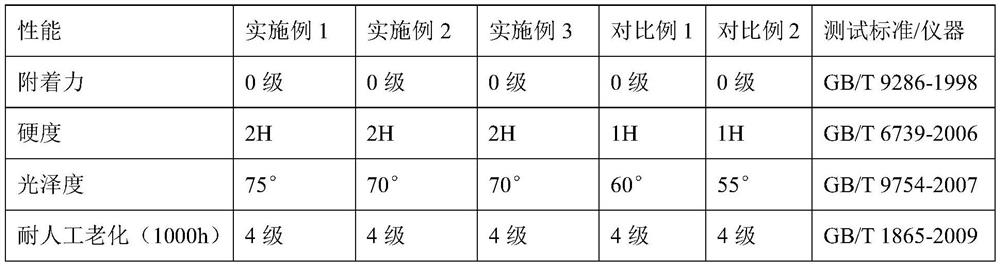

Examples

preparation example Construction

[0076] The preparation method of fluorine-modified acrylic acid emulsion is as follows:

[0077] S1: In a four-necked flask equipped with a stirring and reflux condenser, add 200 parts by mass of deionized water, 2 parts by mass of sodium lauryl sulfate and 2 parts by mass of OP-10 emulsifier, and stir for 30 minutes. An emulsifier solution is obtained.

[0078] S2: In a glass reactor, 17 parts by mass of perfluorooctylethyl methacrylate, 50 parts by mass of butyl methacrylate and 3 parts by mass of methacrylic acid were mixed uniformly, and the 100 parts obtained in S1 Parts by mass of the emulsifier solution was added into a glass reactor, stirred evenly, and ultrasonically emulsified for 1 hour to obtain a monomer pre-emulsion.

[0079] S3: Heat 100 parts by mass of emulsifier solution to 80° C., and add 100 parts by mass of monomer pre-emulsion and 2 parts by mass of potassium persulfate aqueous solution (4 wt %) dropwise under nitrogen protection. The dropwise addition ...

Embodiment 1

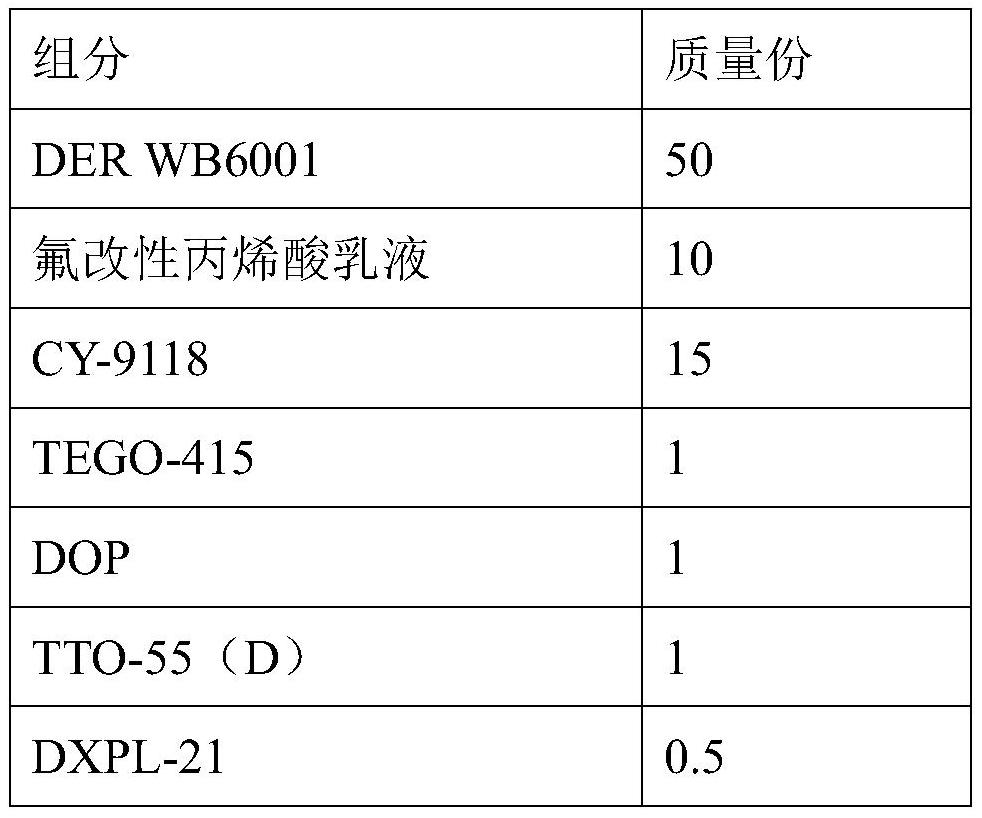

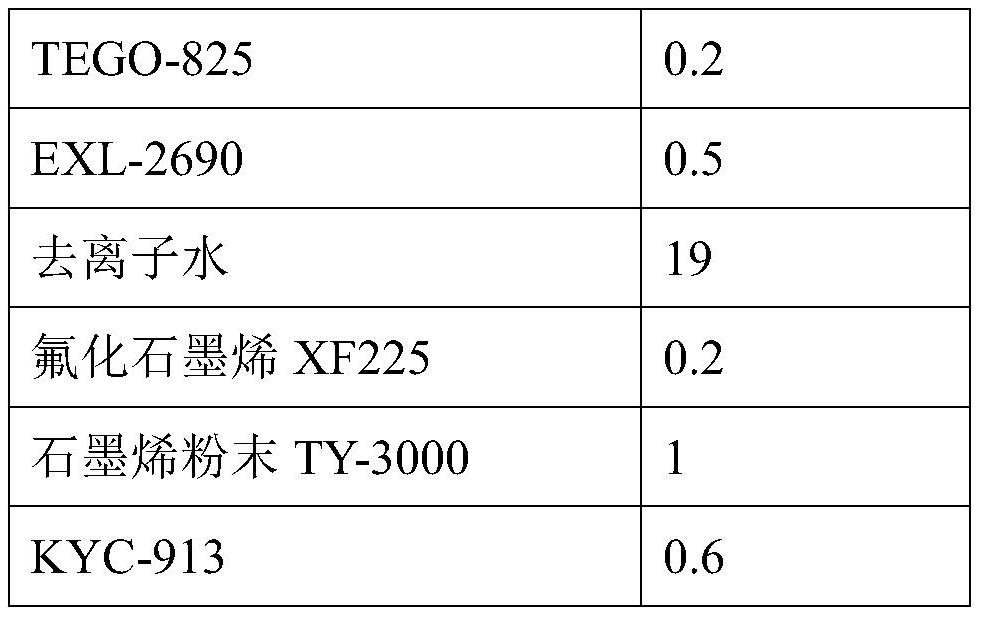

[0083] The composition of the coating A component of Example 1 is shown in Table 1.

[0084] The A component composition of table 1 embodiment 1 coating

[0085] components parts by mass DER WB6001 60 Fluorine modified acrylic emulsion 5 CY-9118 10 BYK-306 1 DOP 1 P25 1 DXPL-21 0.5 TEGO-825 0.2 EXL-2690 0.5 Deionized water 20.2 Fluorinated graphene XF225 0.05 Graphene powder TY-3000 0.25 KYC-913 0.3

[0086] The preparation method of the aqueous fluorinated graphene coating of embodiment 1 is as follows:

[0087] Add nano-dispersant KYC-913, fluorinated graphene powder, graphene powder, and deionized water into the glass reactor according to the ratio in Table 1, first stir at 900r / min for 1 hour, then ultrasonically disperse for 30 minutes, and ultrasonically The power is 1.5kW, and the graphene dispersion suspension is obtained after discharging.

[0088] Put the remaining materials...

Embodiment 2

[0092] The composition of the coating A component of Example 2 is shown in Table 2.

[0093] The A component composition of table 2 embodiment 2 coatings

[0094] components parts by mass DER WB6001 50 Fluorine modified acrylic emulsion 15 CY-9118 10 BYK-306 1 DOP 1 P25 1 DXPL-21 0.5 TEGO-825 0.2 EXL-2690 0.5 Deionized water 19.9 Fluorinated graphene XF225 0.1 Graphene powder TY-3000 0.5 KYV-913 0.3

[0095] The only difference between the water-based fluorinated graphene coating in Example 2 and the preparation method in Example 1 is that the materials are added according to the composition of A component in Table 2, and the rest of the preparation methods are the same.

[0096] The coating in this example uses curing agent WB8006 as component B, and the mass ratio of component A to component B is 100:20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com