A kind of anti-mold and antibacterial liquid crystal electronic glass spacer paper and its production process

A glass spacer paper, anti-mildew and anti-bacterial technology, applied in the direction of anti-biological reagent addition, paper, papermaking, etc., to achieve high stiffness, prevent mold pollution, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

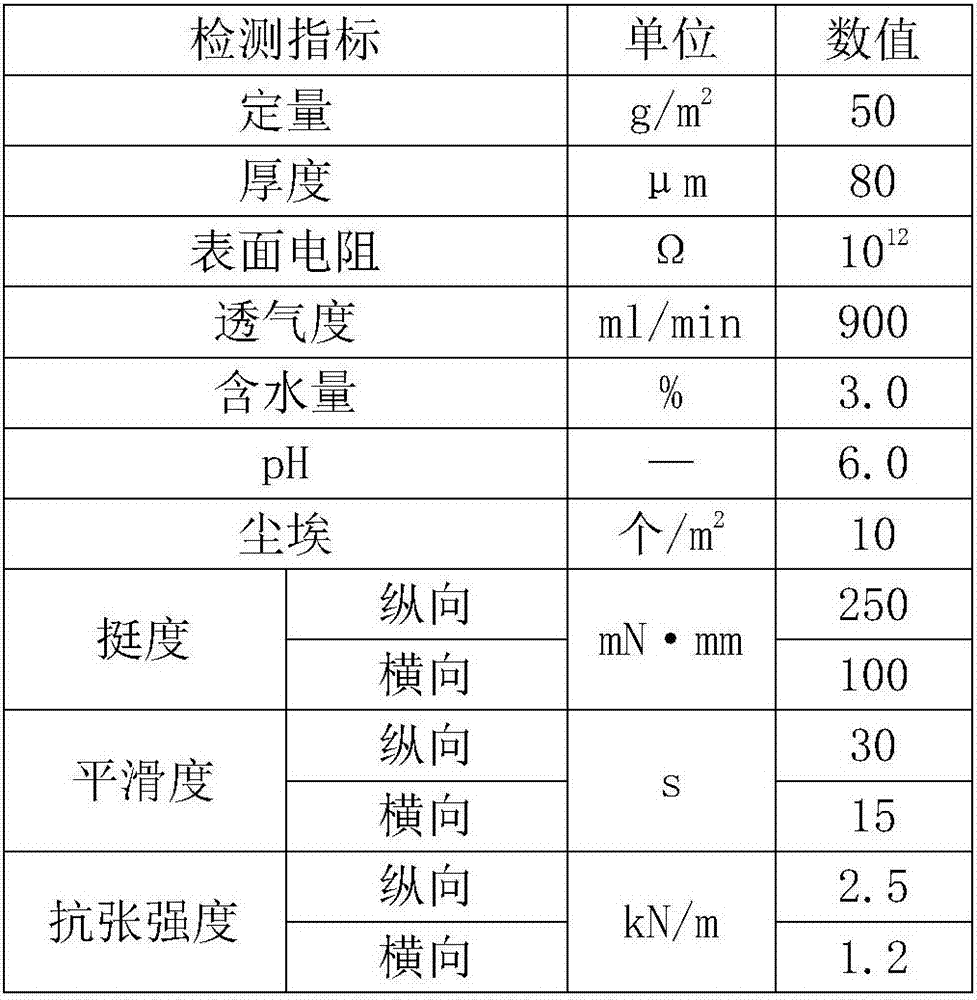

Embodiment 1

[0032] A mildew-proof and antibacterial liquid crystal electronic glass spacer paper, the slurry of the spacer paper includes 50% of the original softwood pulp, 30% of the original hardwood pulp and 20% of the coniferous wood pulp; wherein the original softwood pulp It is mixed with coniferous wood pulp, the beating concentration is 4.0%, and the beating degree is 30°SR; the native hardwood pulp is beaten separately, the beating concentration is 3.5%, and the beating degree is 25°SR.

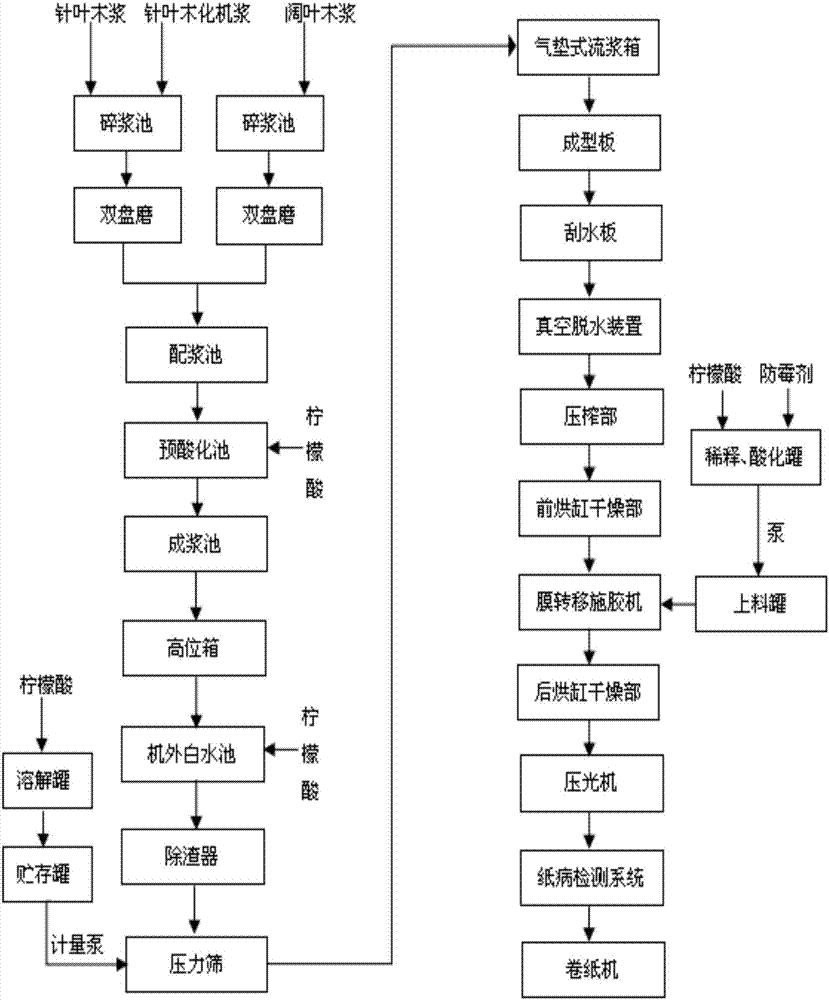

[0033] The production process of the aforementioned anti-mildew and antibacterial liquid crystal electronic glass spacer paper, such as figure 1 shown, including the following steps:

[0034] (1) First mix the raw coniferous wood pulp and coniferous lignified mechanical pulp in proportion and then pulp in a pulper, and the raw hardwood pulp is separately pulped, and then be beaten by double disc mills respectively;

[0035] (2) After mixing the pulp after beating, store it in the slurry mixing ...

Embodiment 2

[0043] A mildew-proof and antibacterial liquid crystal electronic glass spacer paper, the slurry of the spacer paper includes 70% of the original softwood pulp, 10% of the original hardwood pulp and 20% of the coniferous wood pulp; wherein the original softwood pulp Mixed beating with coniferous wood pulp, the beating concentration is 6.0%, and the beating degree is 25°SR; the native hardwood pulp is beaten separately, the beating concentration is 4.5%, the beating degree is 20°SR.

[0044] The production process of the aforementioned anti-mildew and antibacterial liquid crystal electronic glass spacer paper comprises the following steps:

[0045] (1) First mix the raw coniferous wood pulp and coniferous lignified mechanical pulp in proportion and then pulp in a pulper, and the raw hardwood pulp is separately pulped, and then be beaten by double disc mills respectively;

[0046](2) After mixing the pulp after beating, store it in the slurry mixing tank, then transfer it to the...

Embodiment 3

[0054] A mildew-proof and antibacterial liquid crystal electronic glass spacer paper, the slurry of the spacer paper includes 60% of the original softwood pulp, 30% of the original hardwood pulp and 10% of the coniferous wood pulp; wherein the original softwood pulp It was mixed with coniferous wood pulp, the beating concentration was 5.0%, and the beating degree was 28°SR; the native hardwood pulp was beating alone, the beating concentration was 4.0%, and the beating degree was 22°SR.

[0055] The production process of the aforementioned anti-mildew and antibacterial liquid crystal electronic glass spacer paper comprises the following steps:

[0056] (1) First mix the raw coniferous wood pulp and coniferous lignified mechanical pulp in proportion and then pulp in a pulper, and the raw hardwood pulp is separately pulped, and then be beaten by double disc mills respectively;

[0057] (2) Store the slurry after beating in the slurry mixing pool after being mixed, and then carry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com