Preparation method and application of conductive polysiloxane-polyaniline anticorrosive coating

A polysiloxane, anti-corrosion coating technology, applied in anti-corrosion coatings, conductive coatings, coatings and other directions, can solve the problem of insignificant electrochemical corrosion effect, improve anti-corrosion performance and practicability, good anti-corrosion performance, reduce The effect of resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

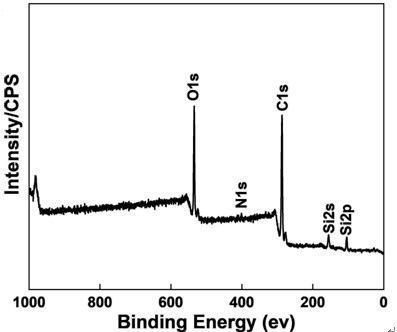

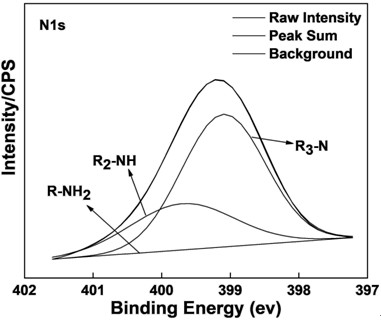

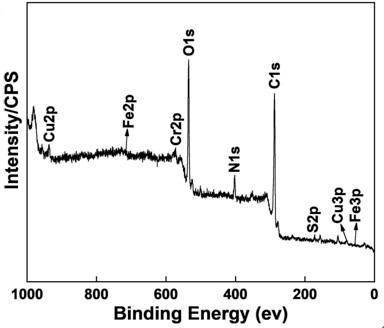

[0040] (1) Preparation of PANIC film: Shanghai CHI660E three-electrode electrochemical workstation was used, the reference electrode was SCE, the counter electrode was platinum wire, the working electrode was 304 stainless steel, polished with 800#~1000# water-phase sandpaper, and then in acetone and ethanol respectively After ultrasonic cleaning for 10 minutes, evaporate to dry naturally. At room temperature, the conductive PANIC film was prepared by cyclic voltammetry, and the electrolyte was 0.2mol / L H 2 SO 4 The aqueous solution was added with 0.2mol / L An, 0.2mol / L DL-MA and 0.2mol / L CAM, and the electrochemical parameters were -0.2~1.0V, 20mV / s and 20 cycles. The obtained samples were heat-treated at 60°C for 12 h in a blast drying oven.

[0041] (2) Preparation of POS suspension: In 50mL absolute ethanol, add 0.1mL distilled water and 0.2g SiO2 , 0.03mol / L DTMS, 0.02mol / L TEOS, 0.05mol / L GPTS and 0.025mol / L OA, the dissolution of OA requires ultrasonic treatment for 10...

Embodiment 2

[0044] (1) Preparation of PANIC film: Shanghai CHI660E three-electrode electrochemical workstation was used, the reference electrode was SCE, the counter electrode was platinum wire, the working electrode was 304 stainless steel, polished with 800#~1000# water-phase sandpaper, and then in acetone and ethanol respectively After ultrasonic cleaning for 10 minutes, evaporate to dry naturally. At room temperature, the conductive PANIC film was prepared by cyclic voltammetry, and the electrolyte was 0.2mol / L H 2 SO 4 The aqueous solution was added with 0.2mol / L An, 0.2mol / L DL-MA and 0.2mol / L CAM, and the electrochemical parameters were -0.2~1.0V, 20mV / s and 20 cycles. The obtained samples were heat-treated at 60°C for 12 h in a blast drying oven.

[0045] (2) Preparation of POS suspension: In 50mL absolute ethanol, add 0.1mL distilled water and 0.3g SiO 2 , 0.03mol / L DTMS, 0.02mol / L TEOS, 0.05mol / L GPTS and 0.025mol / L OA, the dissolution of OA requires ultrasonic treatment for ...

Embodiment 3

[0048] (1) Preparation of PANIC thin film: Shanghai CHI660E three-electrode electrochemical workstation was used, the reference electrode was SCE, the counter electrode was platinum wire, the working electrode was 304 stainless steel, which was polished with 800#~1000# aqueous phase sandpaper, and then in acetone and ethanol respectively After ultrasonic cleaning for 10 minutes, evaporate to dry naturally. At room temperature, the conductive PANIC film was prepared by cyclic voltammetry, and the electrolyte was 0.2mol / L H 2 SO 4 The aqueous solution was added with 0.2mol / L An, 0.2mol / L DL-MA and 0.2mol / L CAM, and the electrochemical parameters were -0.2~1.0V, 20mV / s and 20 cycles. The obtained samples were heat-treated at 60°C for 12 h in a blast drying oven.

[0049] (2) Preparation of POS suspension: In 50mL absolute ethanol, add 0.1mL distilled water and 0.4g SiO 2 , 0.03mol / L DTMS, 0.02mol / L TEOS, 0.05mol / L GPTS and 0.025mol / L OA, the dissolution of OA requires ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water droplet contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com