Apparatus and method for continuous desalination of seawater

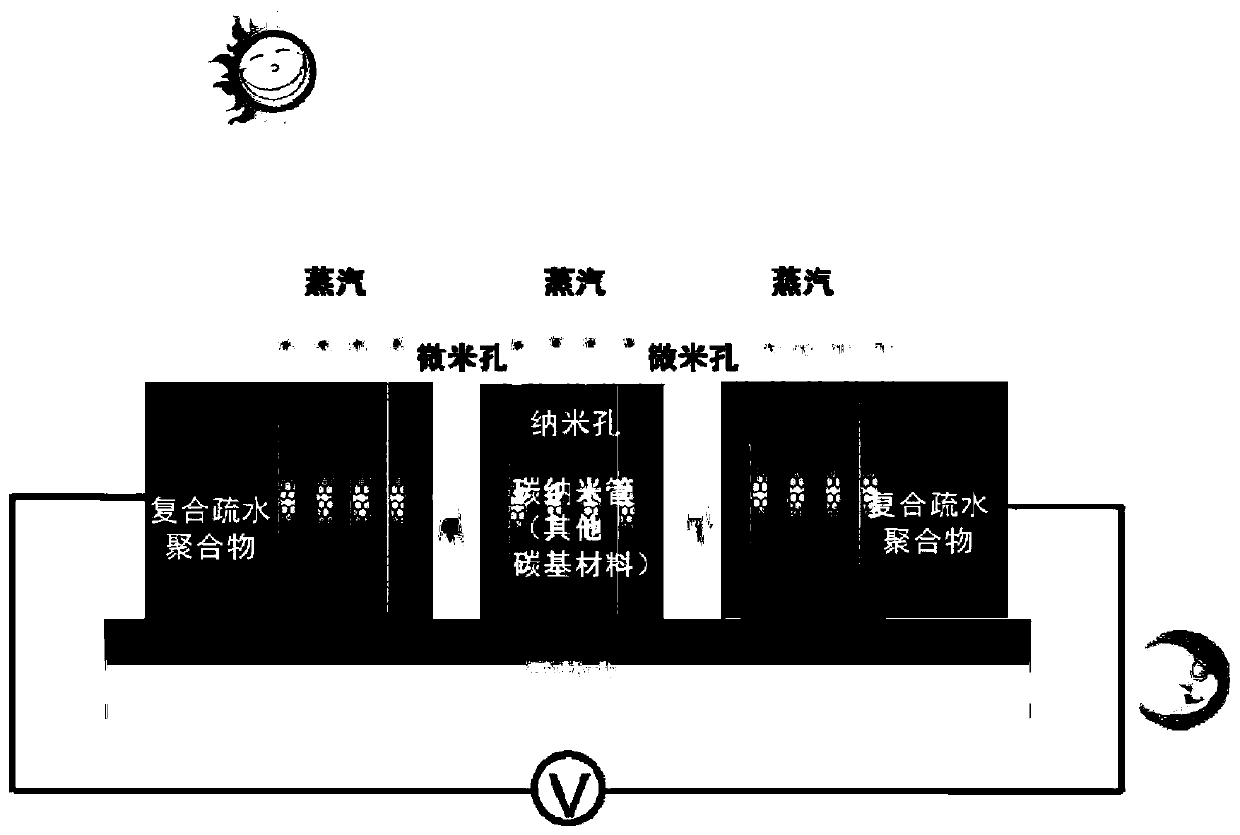

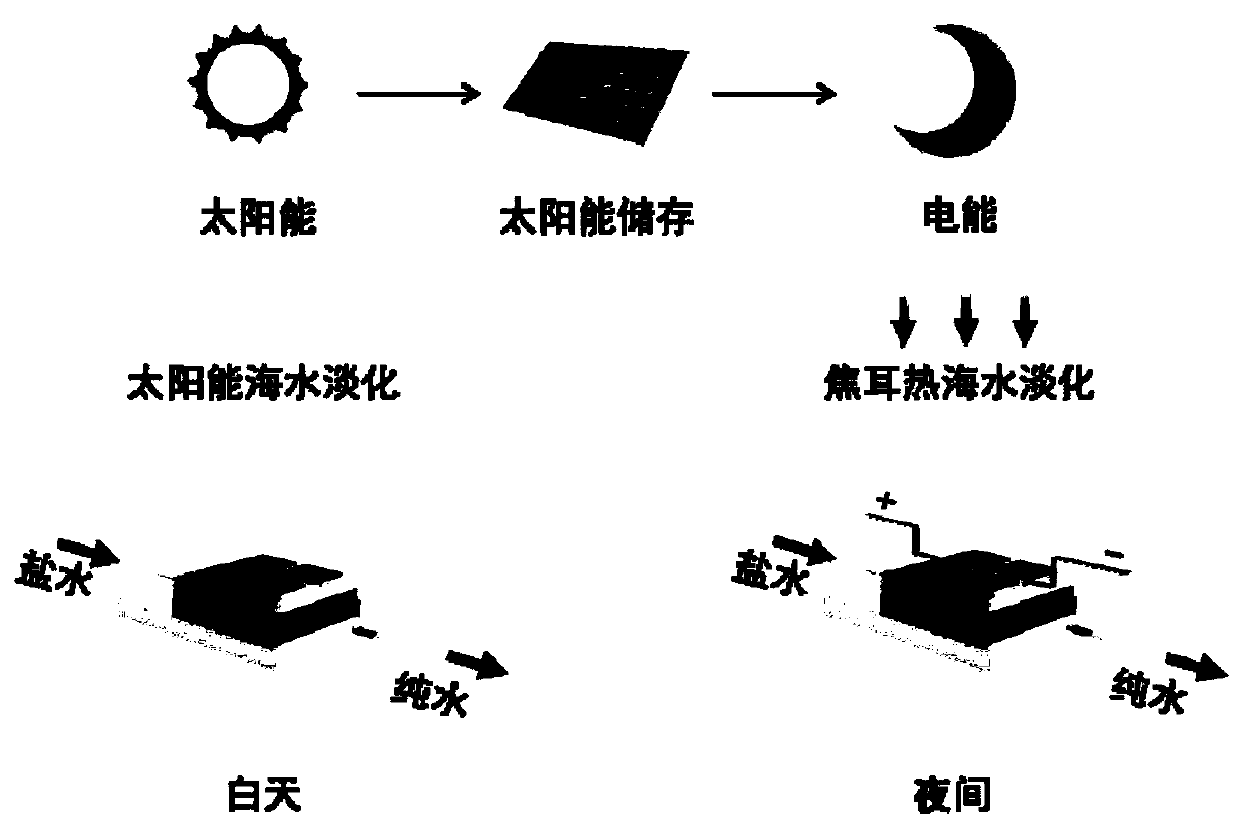

A seawater and water-repellent technology, applied in chemical instruments and methods, seawater treatment, general water supply conservation, etc., can solve problems such as continuous desalination of seawater, and achieve excellent light-to-heat conversion characteristics, strong Joule heating effect, and good mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

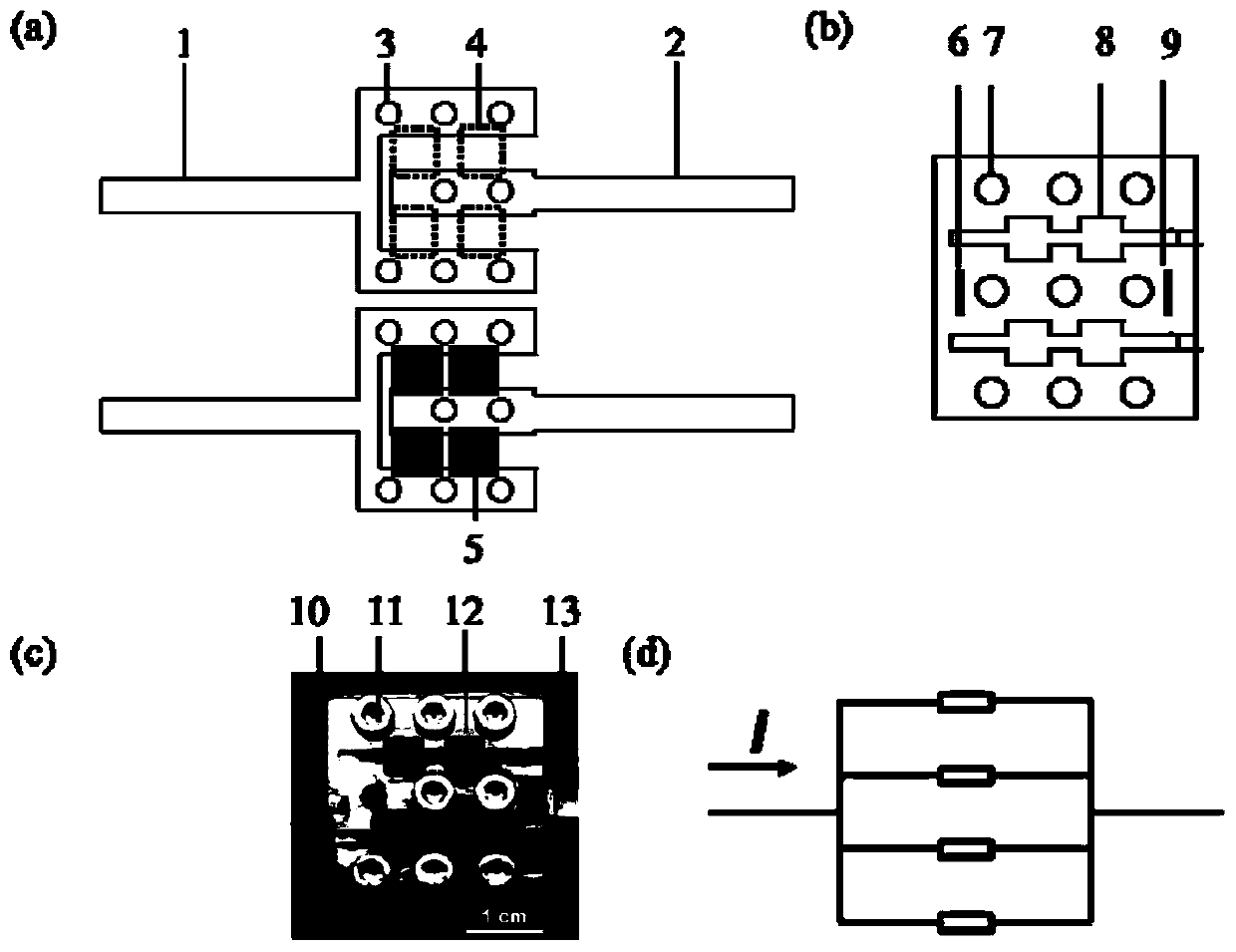

[0048] In the first step, using toluene as a carbon source and ferrocene as a catalyst, configure a 4% ferrocene / toluene solution, and use the floating assisted catalytic method (FCCVD) to grow at 740°C to prepare a wide-diameter (~80nm), High crystallinity (I G / D ≈2.51), high density (0.17 g / cm 3 ), highly controllable (20-1000μm) carbon nanotube arrays, such as image 3 Mix polydimethylsiloxane (PDMS) A and B components in a ratio of 10:1, remove air bubbles for 30 minutes, drop onto the surface of the carbon nanotube array with a pipette, let stand for 30 minutes after the array is completely infiltrated, set the spinner Coating procedure ① 500r-20s; ② 3000r-40s to remove excess resin, curing at 70°C for 3 h. After the curing is complete, the substrate is peeled off, the surface is polished to expose the ends of the carbon tubes, and the film is sliced with an ultra-thin microtome to obtain a carbon nanotube array composite hydrophobic film. The surface and side of the ...

Embodiment 2

[0053] In the first step, use the carbon nanotube array composite porous membrane prepared in Example 1, and use conductive silver glue on both sides of the carbon membrane to bond titanium foil as electrodes for external power supply.

[0054] The second step is to fix the DC voltage at 15V, adjust the time for DC voltage to act on the carbon film, for example: 5min, 10min, 15min, 20min, 25min, 30min, 35min, and control the maximum surface temperature of the carbon film within the corresponding time when the voltage reaches 15V and reach stability.

[0055] The third step is to set the DC power supply voltage value and power-on time based on the data debugged in the second step. Only one piece of carbon film is clamped in the clip to realize the desalination of heavy brine (100g / L NaCl). The desalination device and desalination effect refer to Figure 9 (b). During the desalination process, the evaporation rate is 16.66kg / m when the power-on time is 5min, 10min, 15min, 20min...

Embodiment 3

[0057] In the first step, weigh 4mg carbon dragon complex 1#, carbon dragon complex 2#, carbon dragon complex 3#, carbon dragon complex 4# light / electrical responsive molecular powder, carbon dragon complex 1#-4 # are all osmium metal complexes, the molecular formula is as follows Figure 10 , dissolved in 2mL ethanol, ultrasonically mixed for 10min to obtain a photo / electrically responsive carbon dragon complex molecular solution with a concentration of 2mg / mL, using the carbon nanotube array composite porous membrane prepared in Example 1, the upper and lower surfaces of the membrane were co-coated Apply 100μL, 2mg / mL carbon dragon complex 1#, carbon dragon complex 2#, carbon dragon complex 3#, carbon dragon complex 4# photo / electrical responsive molecules, ( Figure 10 Different carbosaurol complex molecules have photo / electrical responsiveness, but different carbosaulon complex molecules have different photoelectric response characteristics).

[0058]In the second step, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com