Magnesium alloy anode oxidation method

A technology of anodizing and magnesium alloys, applied in the direction of anodizing, can solve the problems of unsatisfactory corrosion resistance, burning of the anodized film, different reaction severity, etc., to reduce chemical corrosion, reduce alkalinity, oxide film and so on uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for anodizing magnesium alloys, comprising the steps of:

[0023] Degreasing: using Na 3 PO 4 10~30g / L, Na 2 CO 3 10~50g / L, OP-102~10ml / L to clean the magnesium alloy sample, remove the oil stain on the surface of the magnesium alloy, the temperature is 40~60℃, and the time is 5~15min.

[0024] Pickling: Use 3-10% dilute nitric acid solution to remove oxides and other dirt on the surface of the magnesium alloy. The temperature is room temperature and the time is 10-30s.

[0025] Alkali etching: Use 50-150g / L NaOH solution to remove the residues produced in the pickling step at a temperature of 70-100°C for 3-15 minutes.

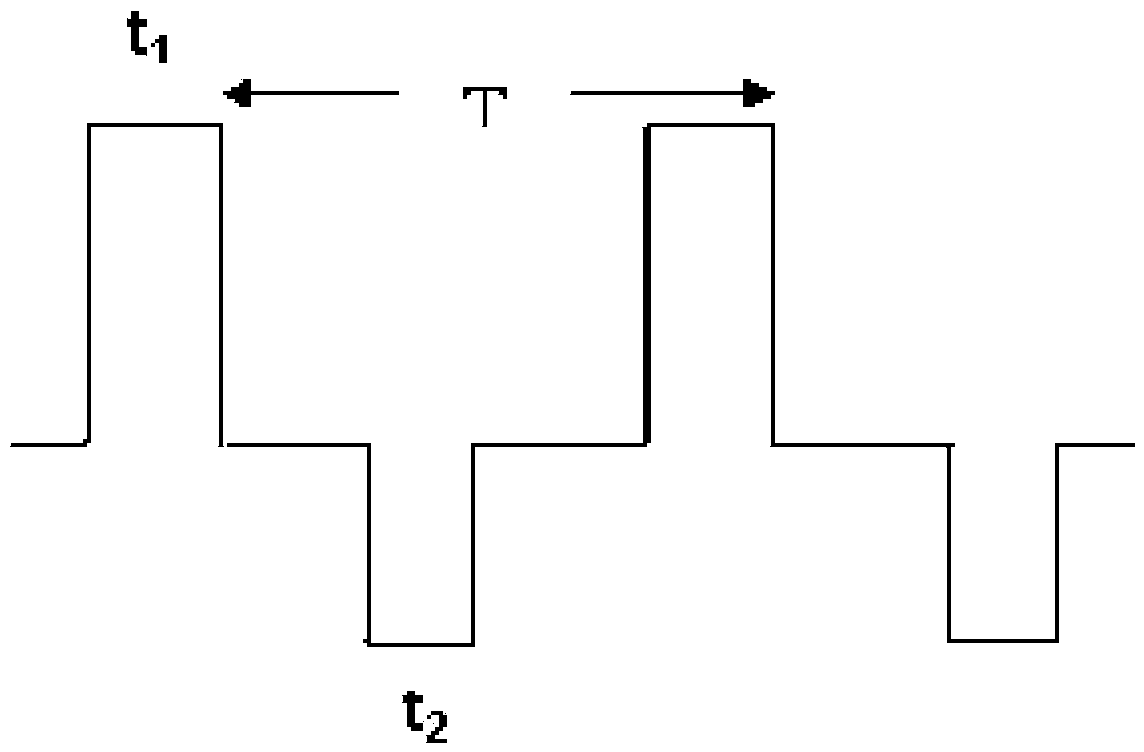

[0026] Anodizing: The electrolyte formula used is NaOH10~100g / L, NaOH 2 SiO 3 10~100g / L and trisodium citrate 2~30g / L. The operating frequency is 300Hz, the positive pulse duty cycle is 10%, the negative pulse duty cycle is 10%, and the positive pulse current density is 1.5A / dm 2 , negative pulse current density 3A / dm 2 , a temperatur...

Embodiment 2

[0030] A method for anodizing magnesium alloys, comprising the steps of:

[0031] Degreasing: using Na 3 PO 4 10~30g / L, Na 2 CO 3 10~50g / L, OP-102~10ml / L to clean the magnesium alloy sample, remove the oil stain on the surface of the magnesium alloy, the temperature is 40~60℃, and the time is 5~15min.

[0032] Pickling: Use 3-10% dilute nitric acid solution to remove oxides and other dirt on the surface of the magnesium alloy. The temperature is room temperature and the time is 10-30s.

[0033] Alkali etching: Use 50-150g / L NaOH solution to remove the residues produced in the pickling step at a temperature of 70-100°C for 3-15 minutes.

[0034] Anodizing: The electrolyte formula used is NaOH10~100g / L, NaOH 2 SiO 3 10~100g / L and trisodium citrate 2~30g / L. The operating frequency is 400Hz, the positive pulse duty cycle is 5%, the negative pulse duty cycle is 10%, and the positive pulse current density is 2A / dm 2 , negative pulse current density 2A / dm 2 , a temperature o...

Embodiment 3

[0037] A method for anodizing magnesium alloys, comprising the steps of:

[0038] Degreasing: using Na 3 PO 4 10~30g / L, Na 2 CO 3 10~50g / L, OP-102~10ml / L to clean the magnesium alloy sample, remove the oil stain on the surface of the magnesium alloy, the temperature is 40~60℃, and the time is 5~15min.

[0039] Pickling: Use 3-10% dilute nitric acid solution to remove oxides and other dirt on the surface of the magnesium alloy. The temperature is room temperature and the time is 10-30s.

[0040] Alkali etching: Use 50-150g / L NaOH solution to remove the residues produced in the pickling step at a temperature of 70-100°C for 3-15 minutes.

[0041] Anodizing: The electrolyte formula used is NaOH10~100g / L, NaOH 2 SiO 3 10~100g / L and trisodium citrate 2~30g / L. The operating frequency is 400Hz, the positive pulse duty cycle is 10%, the negative pulse duty cycle is 5%, and the positive pulse current density is 1A / dm 2 , negative pulse current density 1A / dm 2 , a temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com