A Mechano-rheological Polishing Method for Fixed-point Release of Chemical Action

A technology of chemical action and action, applied in the high-efficiency field, can solve the problems of high processing cost and adverse effects on the rheological properties of the STP polishing base fluid, and achieve the effects of good surface quality, reduced chemical corrosion of equipment, and favorable post-processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

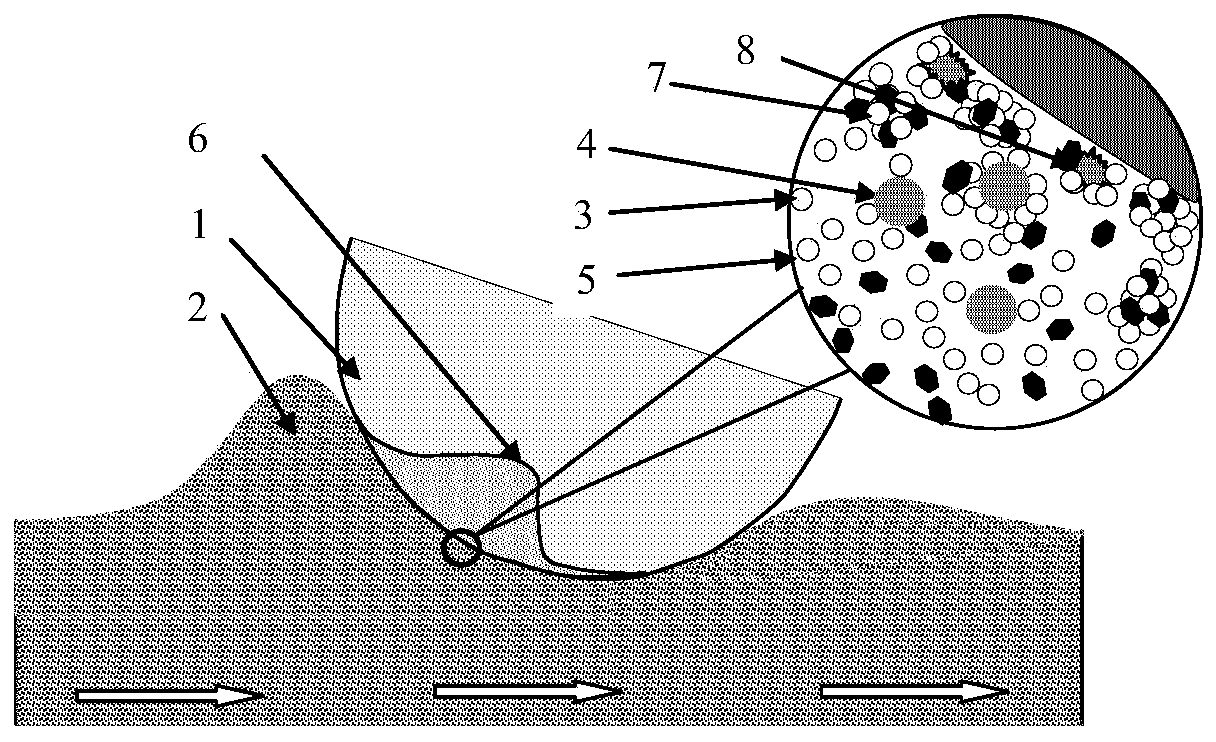

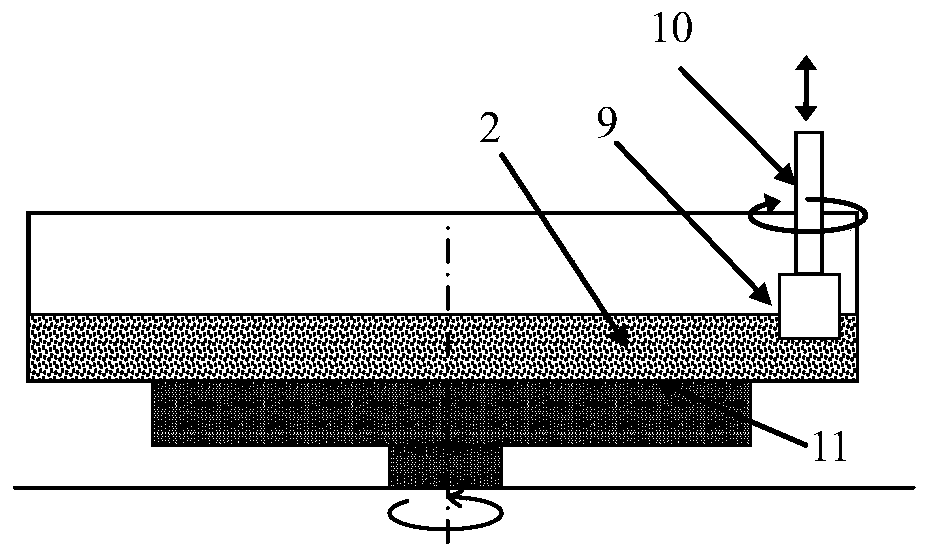

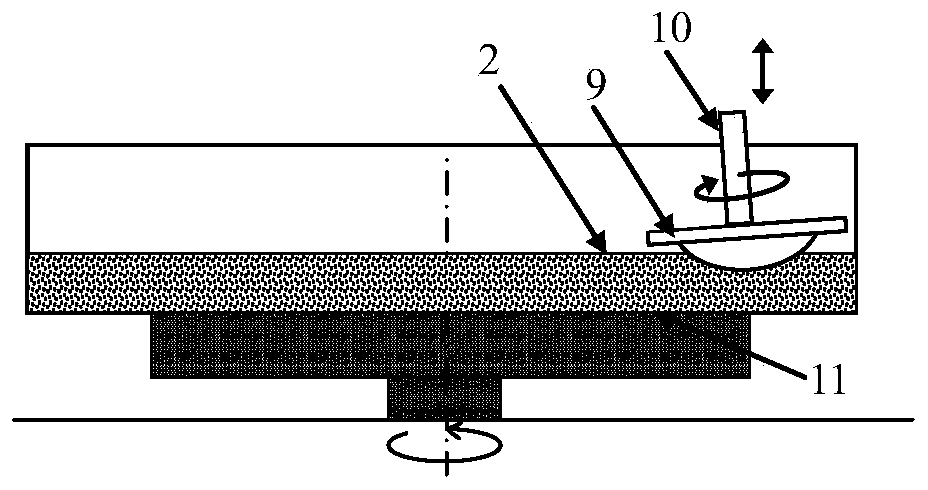

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] refer to Figure 1 ~ Figure 3 , a mechano-rheological polishing method that releases chemical action at a fixed point, adding inclusions containing chemical polishing fluid to the non-Newtonian fluid polishing fluid with shear thickening effect; during the polishing process, as the polishing fluid moves relative to the workpiece As the speed increases, the shear force caused by the workpiece to the polishing liquid increases continuously, and the polishing liquid produces a rheological phenomenon, and the viscosity increases rapidly; thus, the force of the polishing liquid on the inclusions dispersed in it is also relatively enhanced, and the inclusions are in contact with the polishing liquid. The contact surface of the workpiece is squeezed and broken, and the chemical substances in the inclusions are released to the polished surface of the workpiece; the chem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com