Method for smelting and purifying metal in electro-magnetism composite field and device thereof

A technology of electromagnetic compounding and regional smelting, which is applied in the field of metal purification under the parallel static magnetic field of electromagnetic compounding, can solve the problems of deteriorating the directional migration effect of impurity atoms, the long period required for metal purification, and the inconvenience of operation and process control, so as to shorten the purification cycle , Improve migration speed, high effect of removing metal impurities and purifying metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

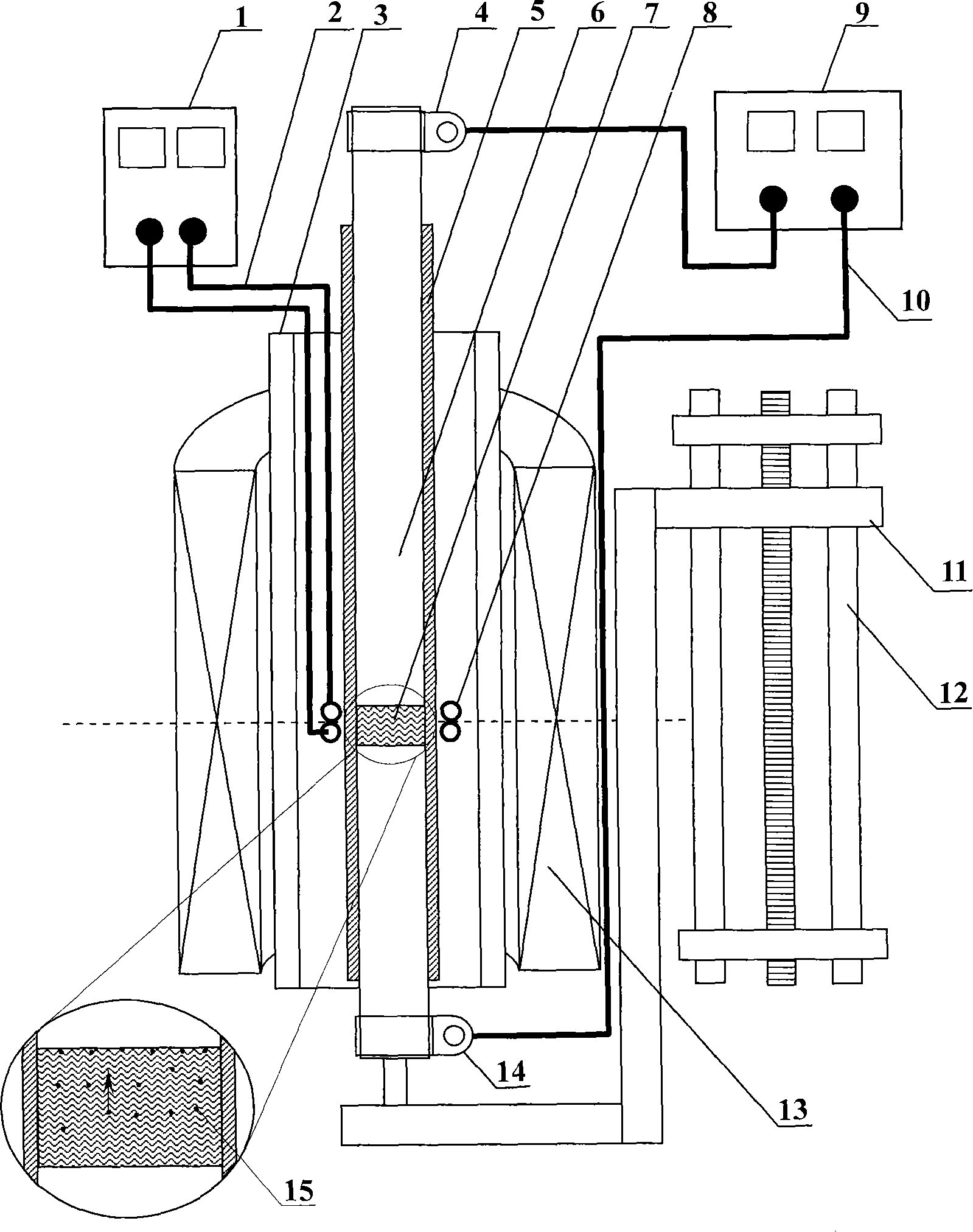

[0014] Embodiment 1: In this embodiment, the method of regional smelting and purifying metal under the electromagnetic compound field is mainly realized by its special device.

[0015] Referring to Figure 1, the special device used in this embodiment consists of a high-frequency induction power supply 1, a high-frequency current transmission wire 2, a water-cooled copper sleeve 3, a negative electrode 4, a corundum tube 5, an alloy round rod sample 6, and a high-frequency induction coil 8 , DC power supply 9, DC cable 10, drawing slide 11, drawing track 12, superconducting magnet 13 and positive pole 14; In the heating device, the high-frequency induction coil 8 is connected to the external high-frequency induction power supply 1 through the wire 2; the outer side of the high-frequency induction coil 8 is provided with a superconducting magnet 13 surrounded by it; The two ends are respectively connected with the negative pole 4 and the positive pole 14, the negative pole 4 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com