Post insulator electrified sweeping system and method

A post insulator and live cleaning technology, which is applied in the field of electric power engineering, can solve the problems of pollution flashover, high cost, and the inability to clean up the post insulator shed dirt in time, so as to improve the reliability of power supply and reduce the power outage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

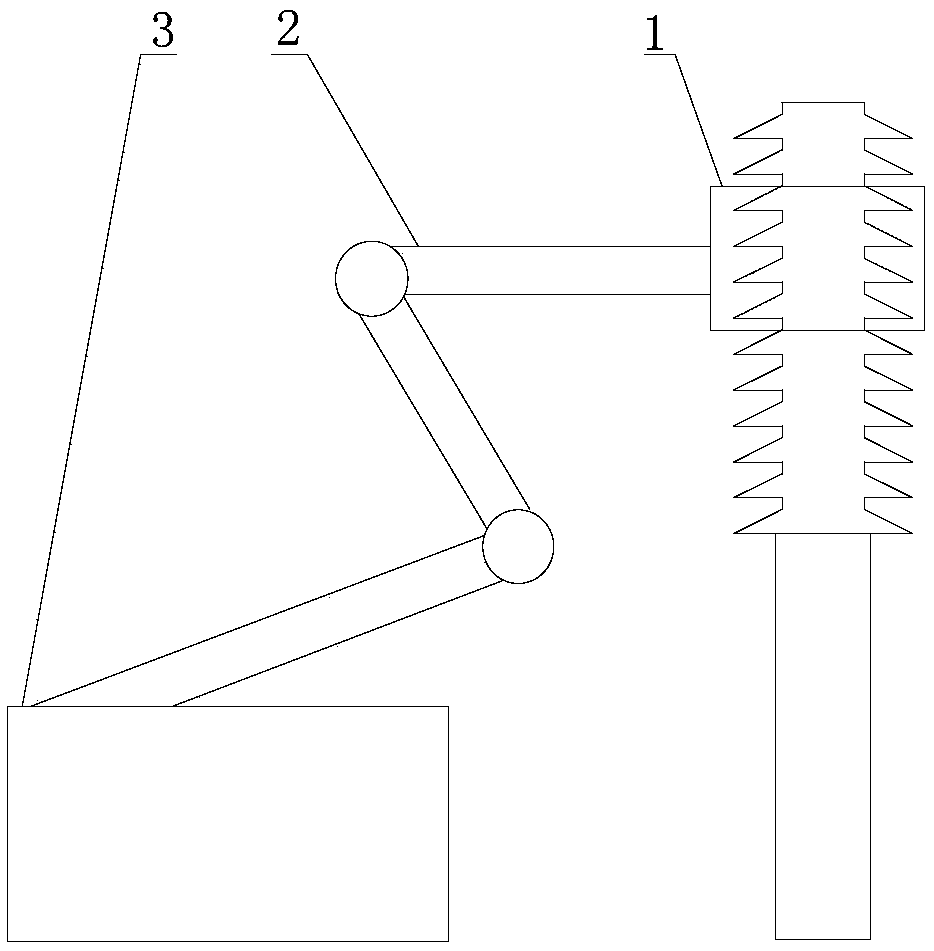

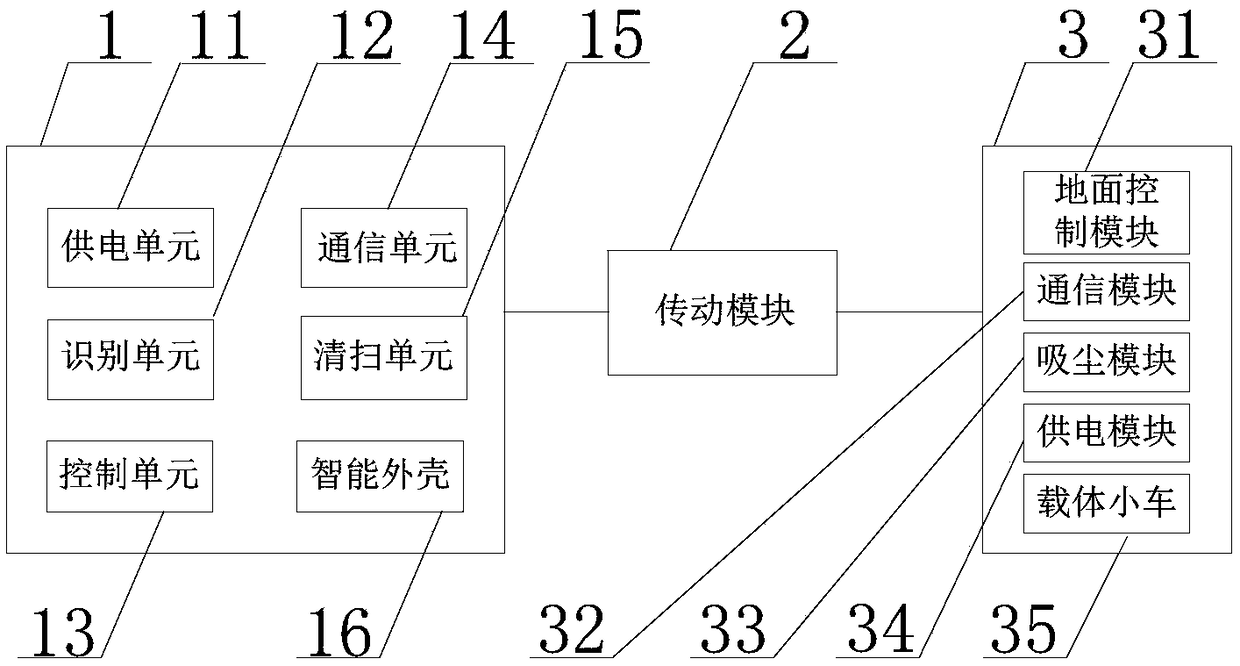

[0070] see Figure 1~5 , the invention discloses a post insulator live cleaning system, comprising a cleaning module 1, a transmission module 2 and a ground system 3;

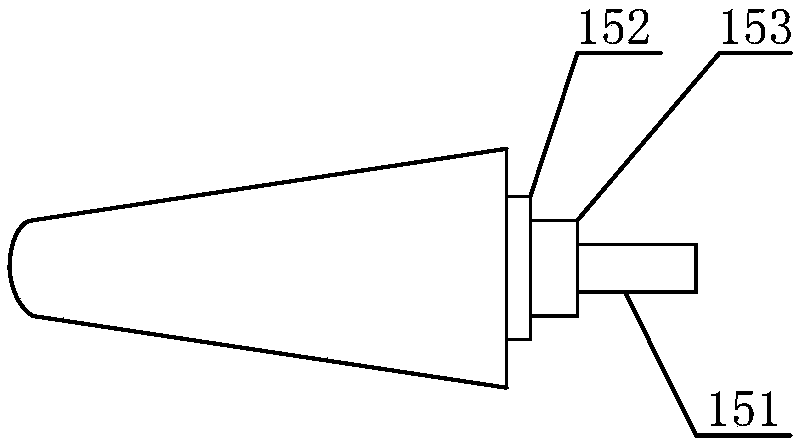

[0071] The cleaning module 1 includes an identification unit 12, a control unit 13, a communication unit 14, a cleaning unit 15 and a smart housing 16; the smart housing 16 is cylindrical and can be opened and closed along one side of the cylinder wall; the identification unit 12, The control unit 13, the communication unit 14 and the cleaning unit 15 are integrated and installed inside the smart housing 16; the identification unit 12, the communication unit 14, the cleaning unit 15 and the smart housing 16 are all electrically connected to the control unit 13;

[0072] The upper end of the transmission module 2 is fixedly connected to the central position on the axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com