Rolling tension control system with multiple tension control modes

A technology of tension control and mode, which is applied in the direction of thin material processing, winding strip, transportation and packaging, etc. It can solve the problems of single receiving material, unsuitable for diversified materials, and single control mode, so as to achieve easy grasp and solve the problem of winding Core wrinkle, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

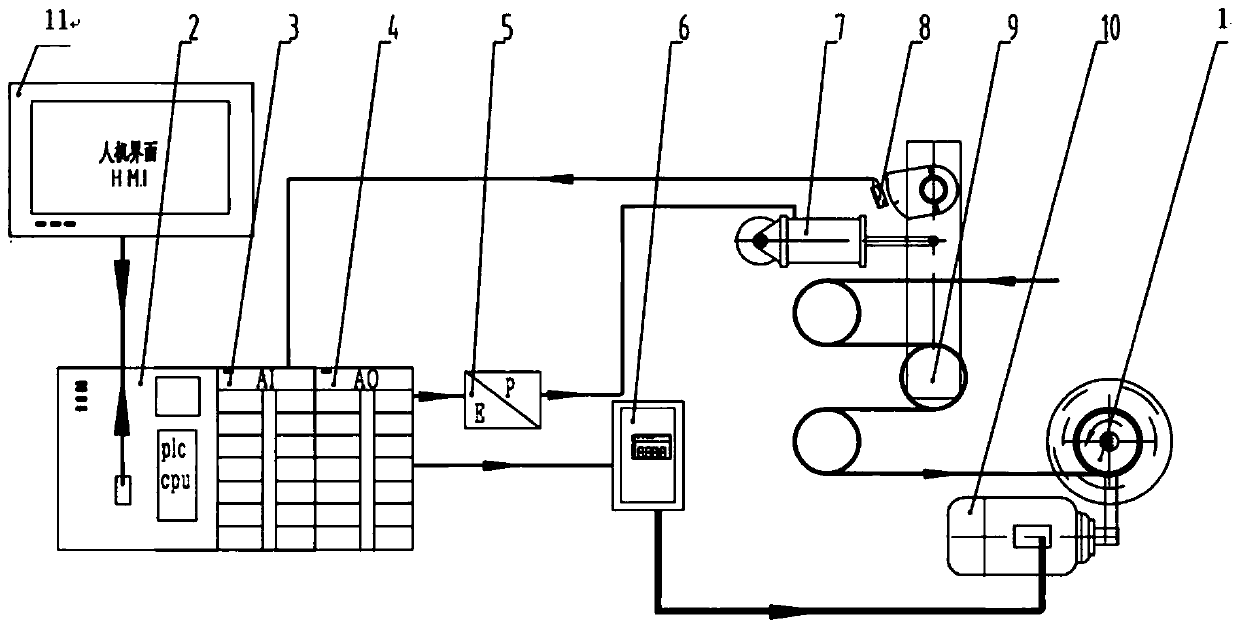

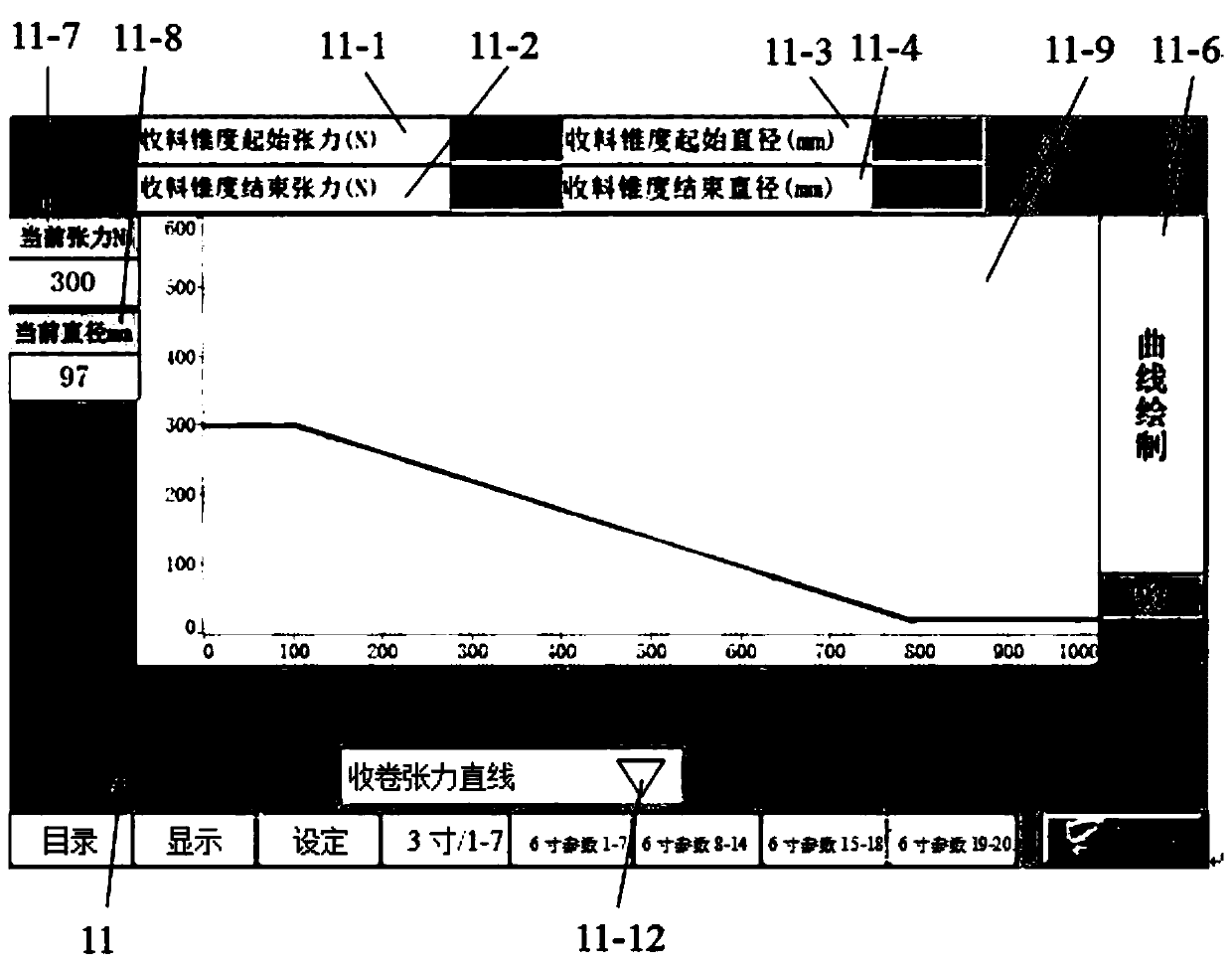

[0083] Adopt the material receiving tension control system of the present invention to carry out the material receiving tension linear control, set the following parameters on the man-machine interface, F1=300N, F2=20N, D1=100mm, D2=800mm;

[0084] F0 indicates the current real-time tension of receiving material, the unit is N; D0 indicates the real-time diameter of receiving material during the operation of the equipment, the unit is mm;

[0085] According to formula (1), when D0<100mm, F0=300N;

[0086] When 100mm≤D0≤800mm,

[0087]

[0088] When D0>800mm, F0=20N;

[0089] The controller PLC can obtain the tension curve diagram through the above logic operations, click the curve drawing unit 11-6 on the man-machine interface 11, and the tension curve diagram will be displayed on the tension curve display area 11-9, and the controller PLC can obtain the tension curve diagram according to the tension curve Figure real-time adjustment and control of the electric proportion...

Embodiment 2

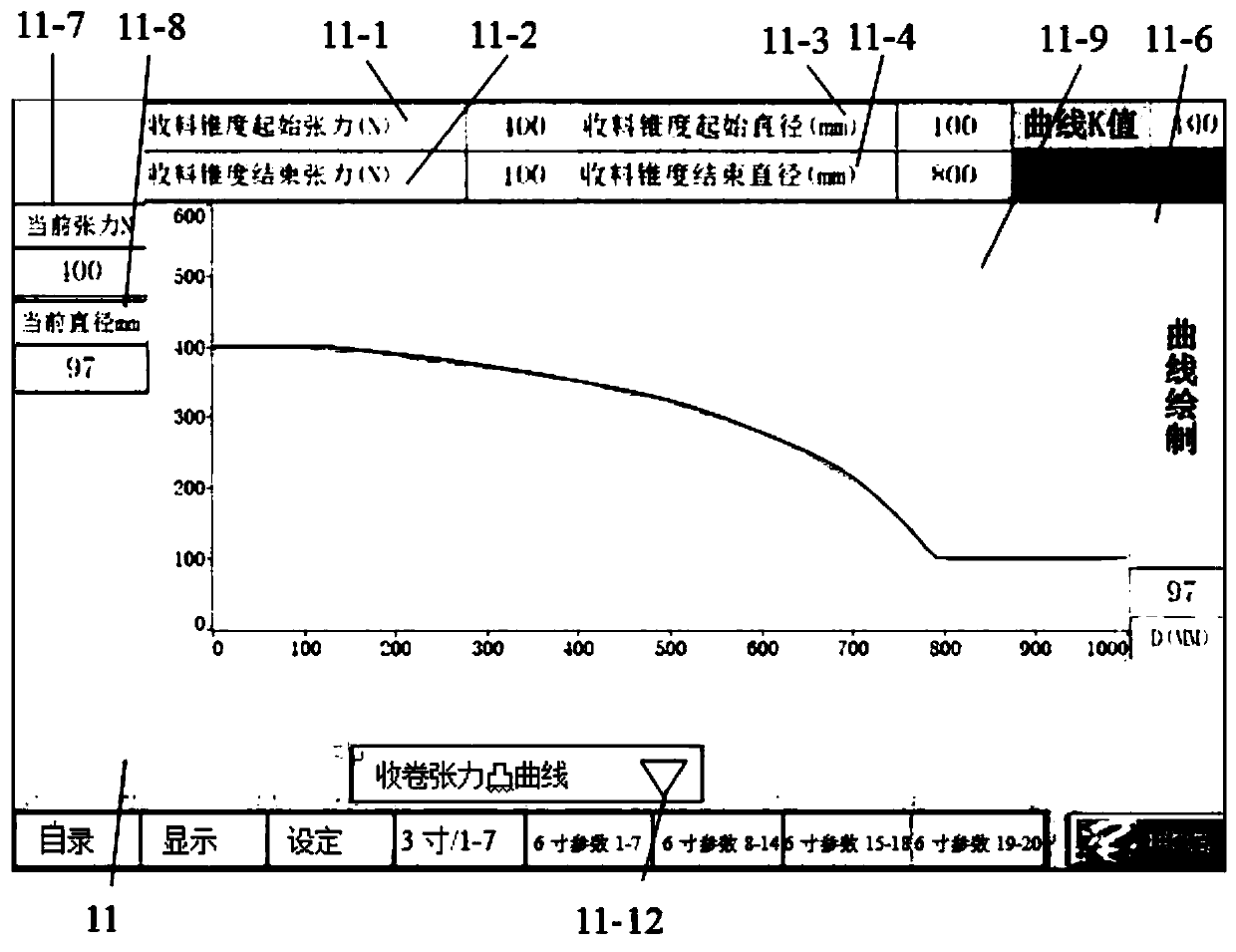

[0091] Adopt the material receiving tension control system of the present invention to carry out material receiving tension convex line control, set the following parameters on the man-machine interface, F1=400N, F2=100N, D1=100mm, D2=800mm, K=100;

[0092] F0 indicates the current real-time tension of receiving material, the unit is N; D0 indicates the real-time diameter of receiving material during the operation of the equipment, the unit is mm;

[0093] According to formula (2), when D0<100mm, F0=400N;

[0094] When 100mm≤D0≤800mm,

[0095]

[0096] When D0>800mm, F0=100N;

[0097] The controller PLC can obtain the tension curve diagram through the above logic operations, click the curve drawing unit 11-6 on the man-machine interface 11, and the tension curve diagram will be displayed on the tension curve display area 11-9, and the controller PLC can obtain the tension curve diagram according to the tension curve Figure real-time adjustment and control of the electric ...

Embodiment 3

[0099] Adopt the material receiving tension control system of the present invention to control the material receiving tension concave line, set the following parameters on the man-machine interface, F1=500N, F2=100N, D1=100mm, D2=800mm, K=100;

[0100] F0 indicates the current real-time tension of receiving material, the unit is N; D0 indicates the real-time diameter of receiving material during the operation of the equipment, the unit is mm;

[0101] According to the formula (3), when D0<100mm, F0=500N;

[0102] When 100mm≤D0≤800mm,

[0103]

[0104] When D0>800mm, F0=100N;

[0105] The controller PLC can obtain the tension curve diagram through the above logic operations, click the curve drawing unit 11-6 on the man-machine interface 11, and the tension curve diagram will be displayed on the tension curve display area 11-9, and the controller PLC can obtain the tension curve diagram according to the tension curve Figure real-time adjustment and control of the electric pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com