Non-stick earth pack roller

A technology for pressing rollers and soil, which is applied in the field of pressing rollers, which can solve the problems of the pressing rollers sticking to the soil, uneven soil compactness, and high energy consumption of traction machinery, and achieve uniform soil compactness, solve the problem of sticking soil, and smooth the soil surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

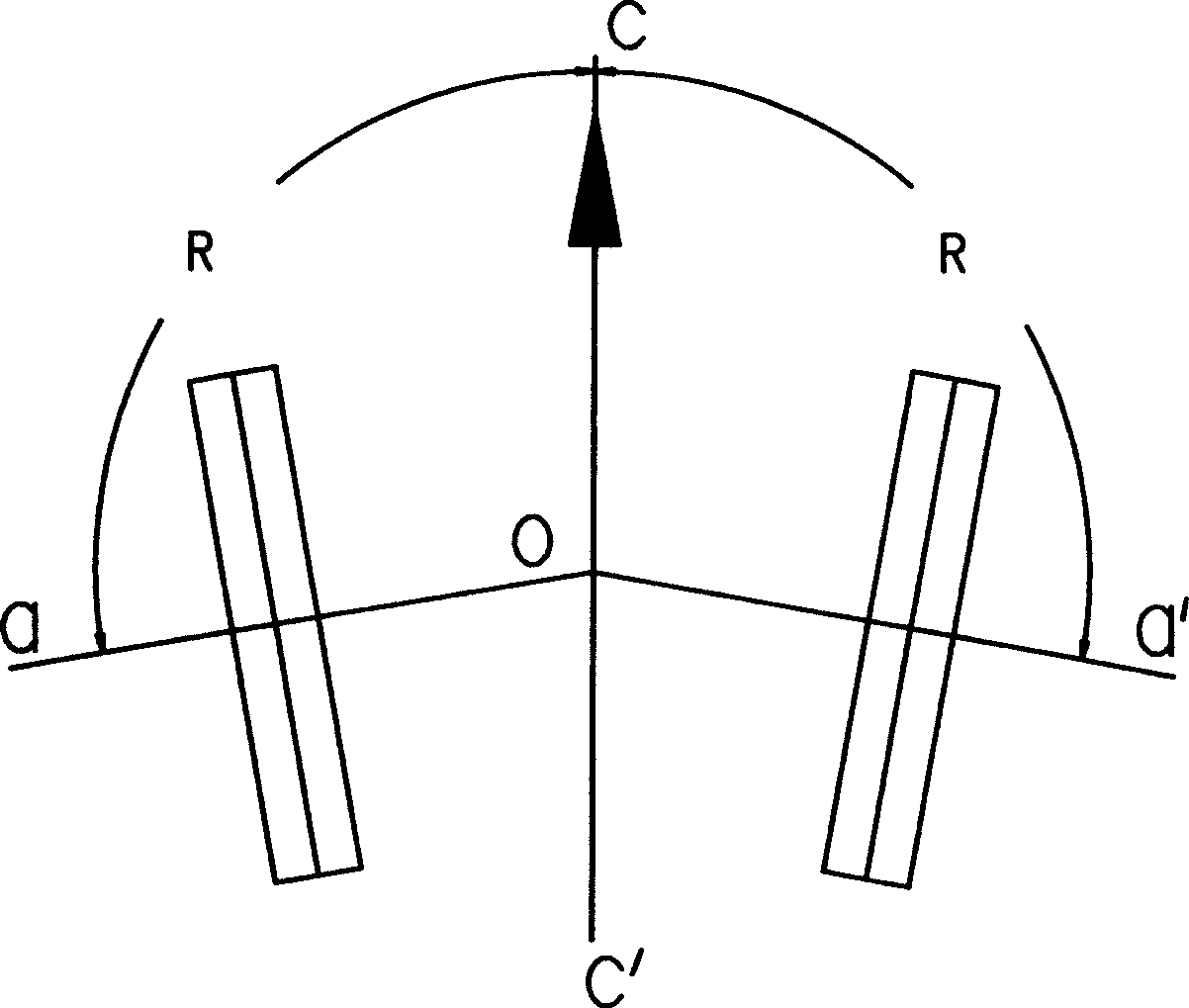

[0012] refer to figure 1 , 2 , a kind of non-clay soil pressing roll, is made of a roll frame and 2 or 4 rollers symmetrically arranged on both sides of the longitudinal axis c-c' of the roll frame. c-c' forms an included angle R of 91-99 degrees along the traveling direction of the pressure roller.

[0013] In order to realize the adjustable angle between the roller axis and the longitudinal axis of the roll stand, the rollers can be arranged on the roll stand in the manner shown in Figures 7 and 8. In the figure, 1 and 6 are pressing rollers, 2 and 5 are swing arms, and 3 Be a roller frame, 4 is a leading screw pair, 7 is a fork support, and 8 is a roller shaft. The roller frame 3 is provided with a lead screw pair 4 and a swing arm 2, 5 device for adjusting the angle of the roller axis. Rotating the screw nut can make the lead screw move axially and drive the swing arm to rotate, thereby changing the angle of the roller axis.

Embodiment 2

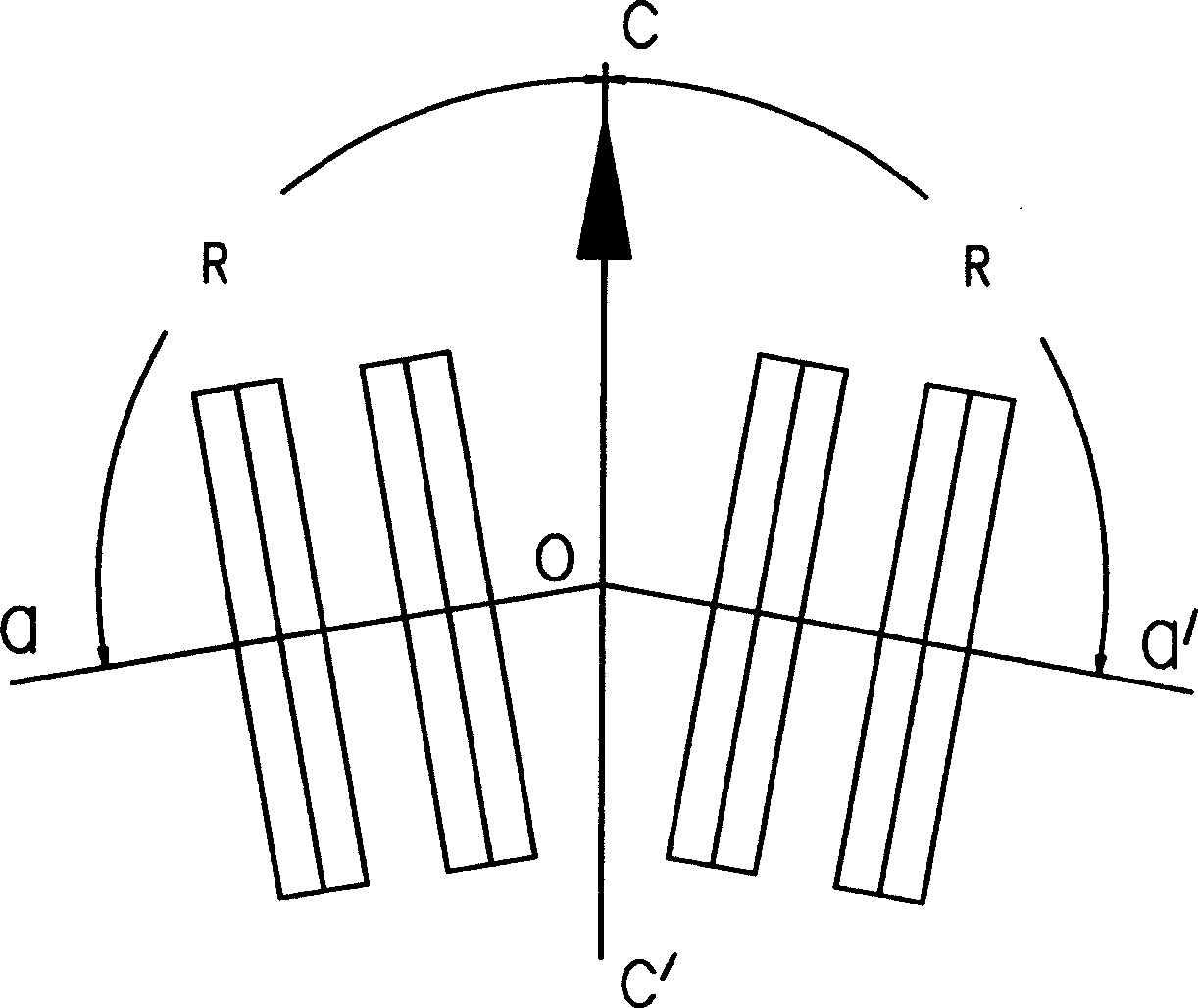

[0015] refer to image 3 , 4 , 5, a kind of non-sticky soil pressure roll, is made of a roll frame and 2 or 4 or 6 rollers symmetrically arranged on both sides of the longitudinal axis c-c' of the roll frame, the axes o-a, o-a' of the rollers An included angle R of 81-89 degrees is formed with the longitudinal axis c-c' of the roll stand along the traveling direction of the pressure roll.

Embodiment 3

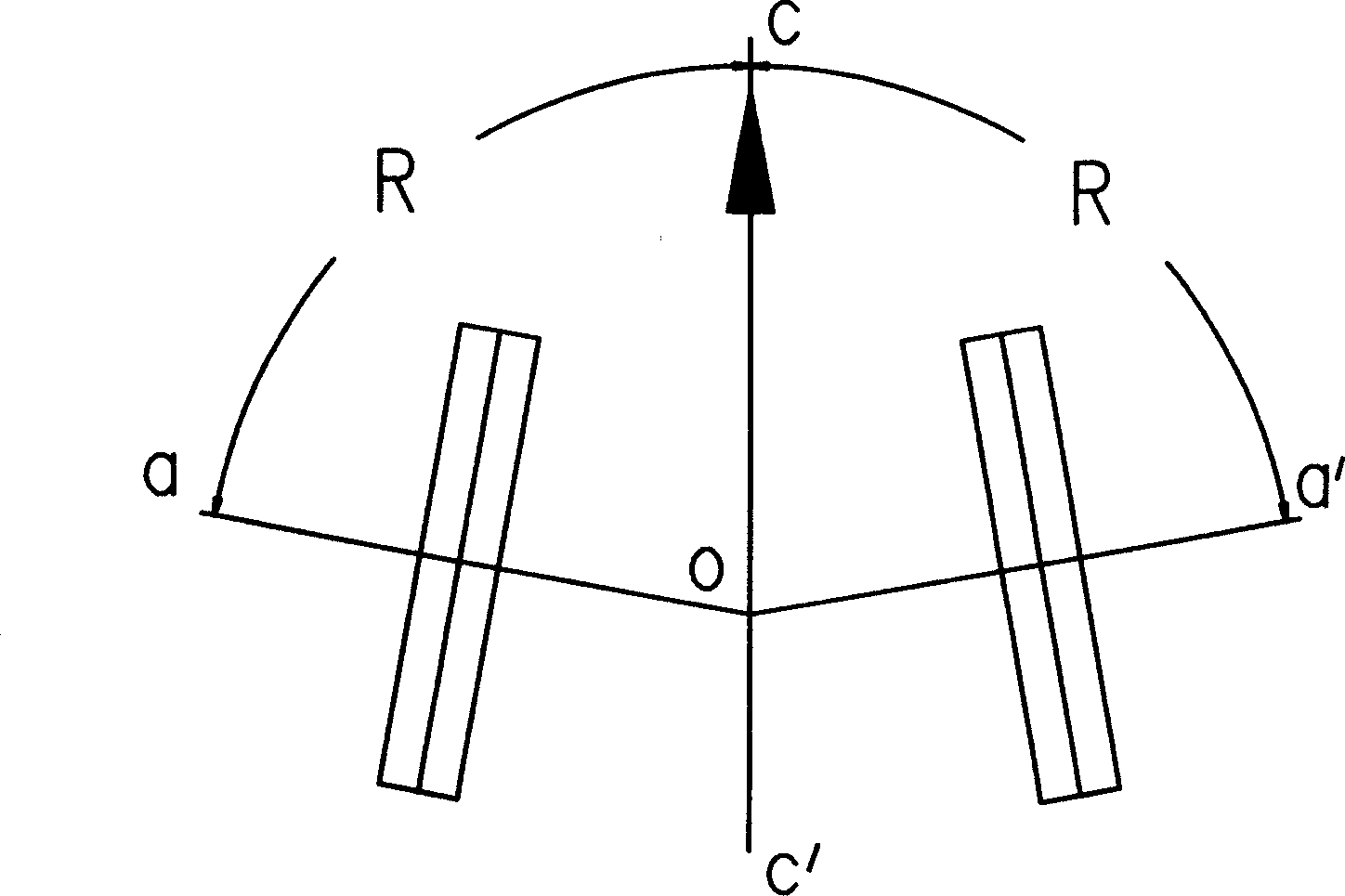

[0017] refer to Figure 6 , a non-clay soil suppression roller, which is composed of a roller frame and 4 rollers symmetrically arranged on both sides of the longitudinal axis c-c′ of the roller frame. The longitudinal axis c-c' forms an included angle R of 81-89 degrees along the direction of travel of the pressure roller; the axes o'-b, o'-b' of the other pair of symmetrical rollers G1 and G4 and the longitudinal axis c-c' of the roller frame are along the direction of the pressure roller The direction of travel forms an included angle R' of 91-99 degrees.

[0018] The pressing roller of the present invention has the characteristics of low cost, uniform soil compactness and smooth surface after pressing. The pressure roller of the present invention only changes the angle between the axis of the roller and the direction of travel (the longitudinal axis of the roller frame of the pressure roller), so that the roller slides while rolling, which can effectively solve the proble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com