Binding machine by means of annular rubber band

A strapping machine and rubber band technology, applied in the direction of bundling materials, etc., can solve the problems of low success rate, affecting the working stability of the machine, and uneven tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

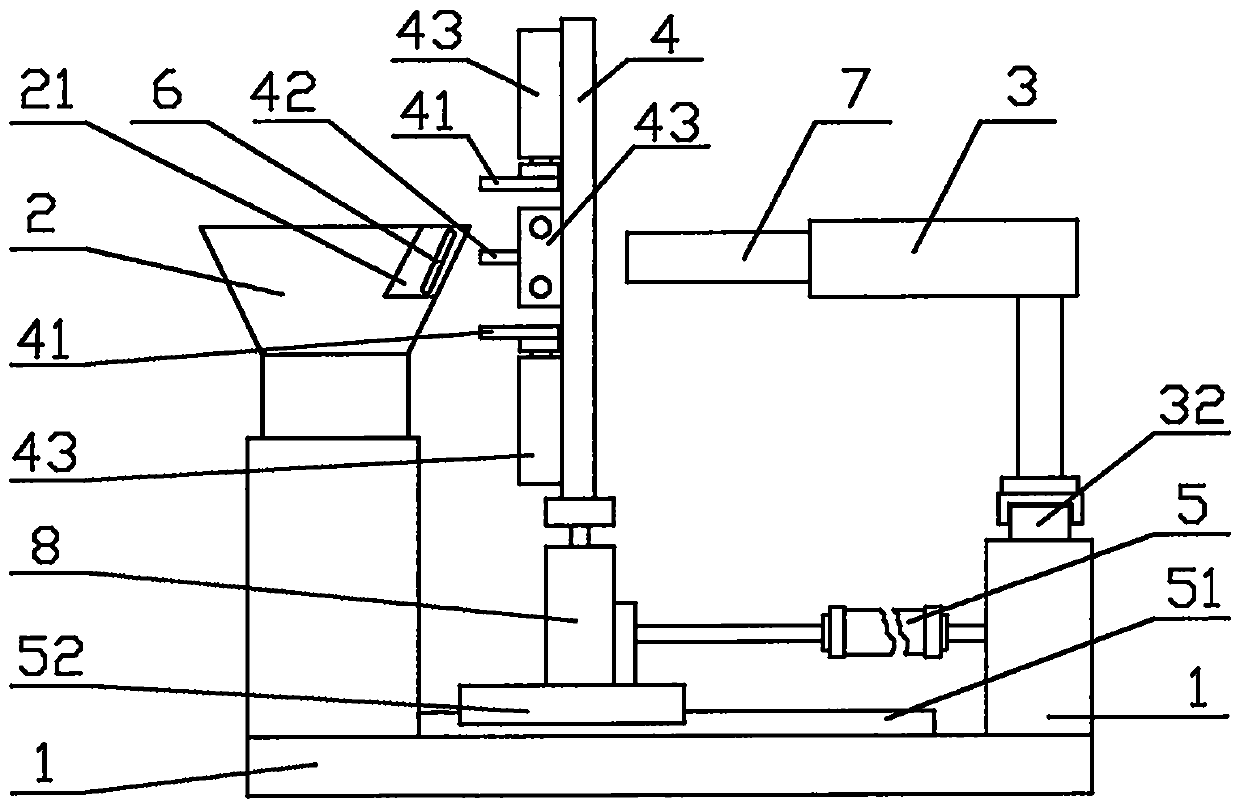

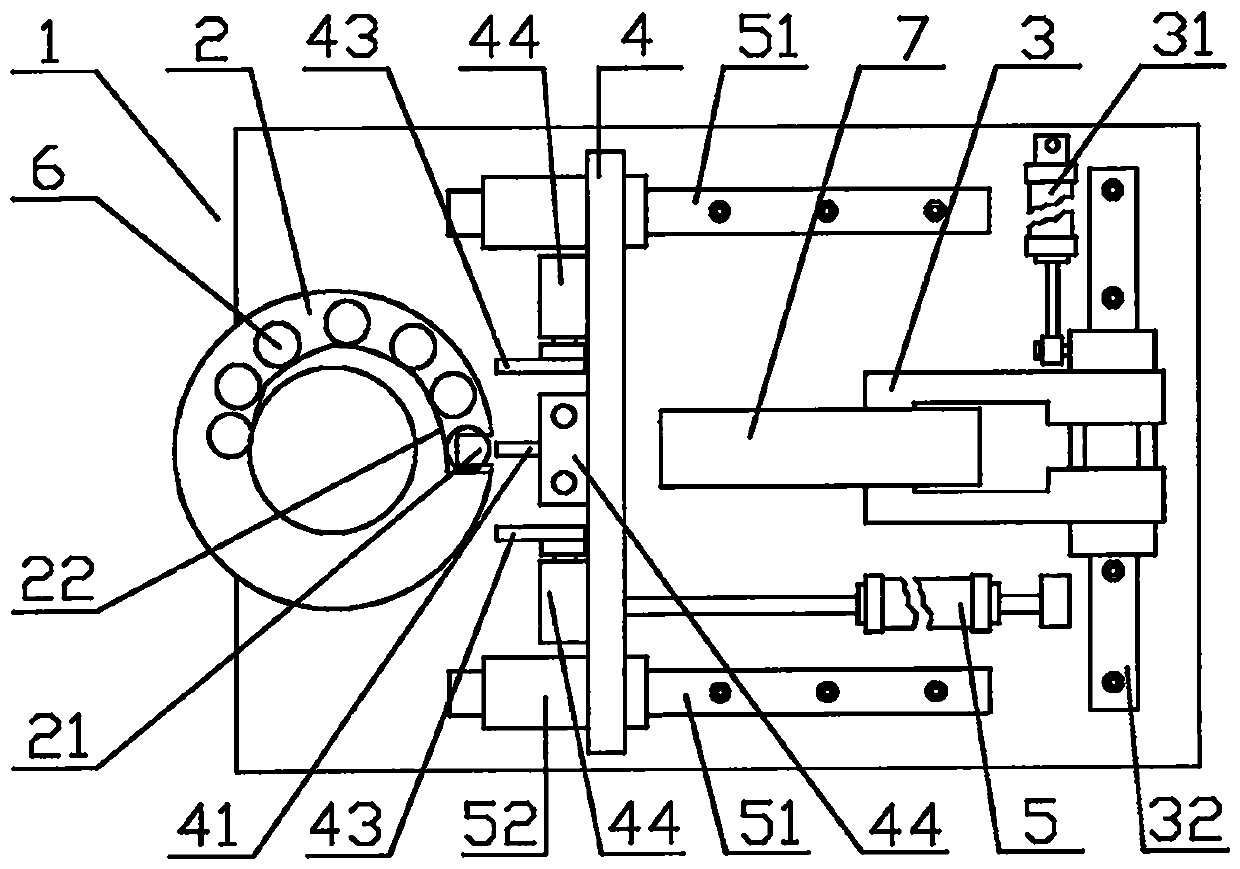

Method used

Image

Examples

Embodiment 2

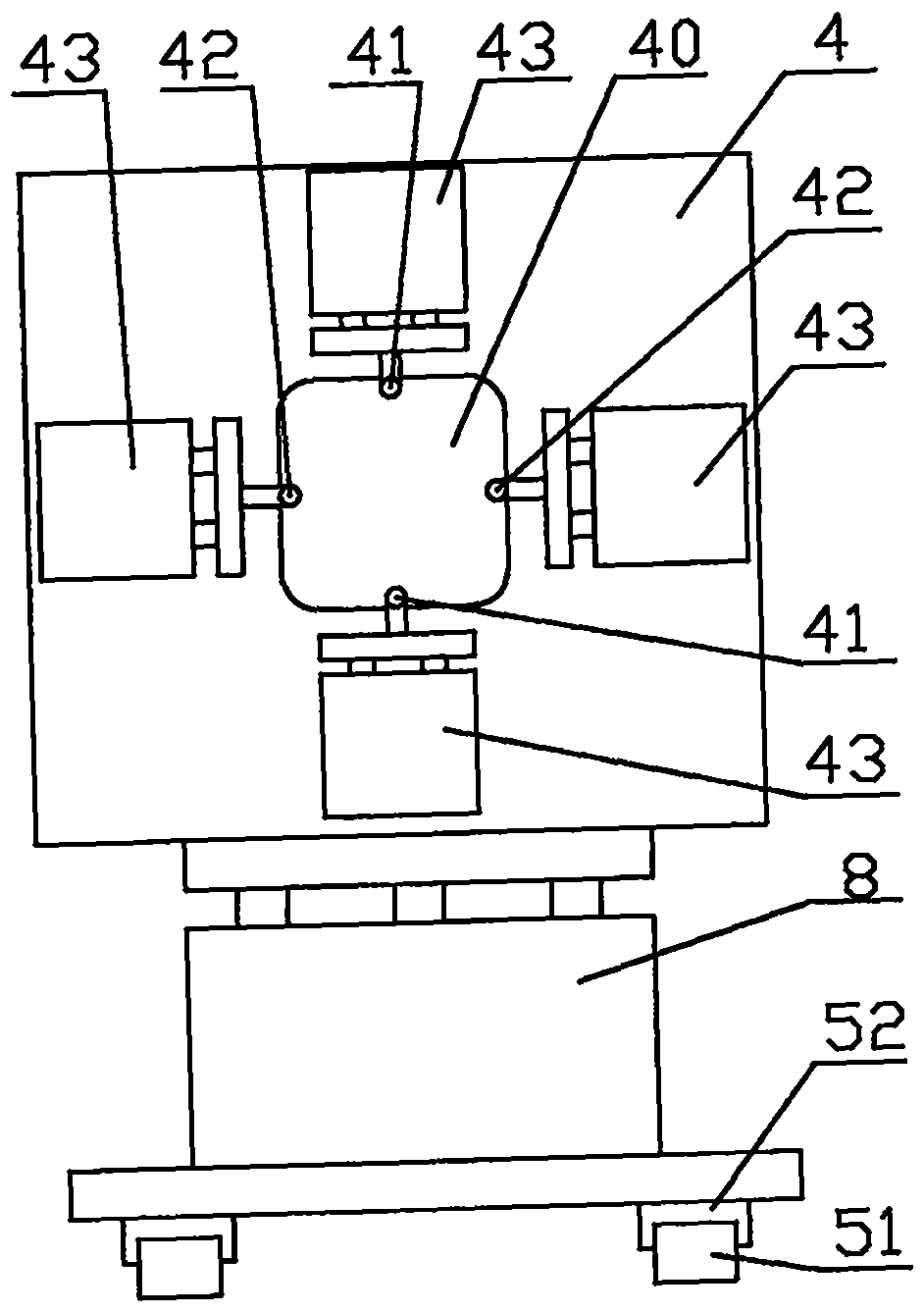

[0039] Embodiment two, such as Figure 8 , Figure 9 , Figure 10 Shown: the main differences between embodiment two and embodiment one are: first: the opening direction movement mechanism includes: frame 80, slide blocks are respectively installed on both sides of the bracket 4, so that the bracket 4 slides up and down and is arranged on the frame 80 Its two: the insertion motion mechanism is a kind of swing cylinder 53; its three: the delivery direction of the plastic bag delivery device is the left and right direction delivery, and the plastic bags folded into elongated strips are in the left and right horizontal state on the mechanical clamp 3, which is equivalent to The posture plane of the plastic bag 7 in the first embodiment is rotated 90 degrees counterclockwise.

[0040] Such as Figure 8 Shown: a frame 80 is set, a swing cylinder 53 is installed on the lower end of one side of the frame 80 and the frame 1, a guide rail 82 is installed up and down on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com