Safety high-temperature and high-pressure reaction vessel sealing structure for solvothermal synthesis

A high-temperature, high-pressure, sealed structure technology, applied in the direction of pressure vessels, pressure vessels/vacuum vessels used in chemical processes, etc., can solve the problems of reducing the sealing performance of the autoclave, prone to explosion, leakage and volatilization of autoclave materials, etc. Compact design, safe and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

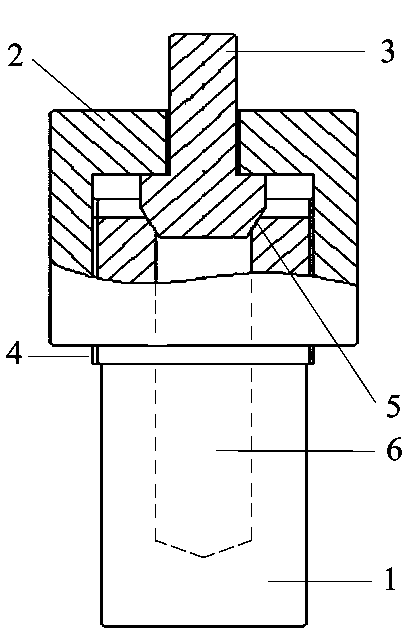

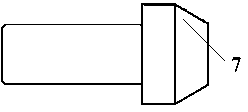

[0008] figure 1 It is a schematic diagram of an embodiment of the sealing structure of a safe solvothermal synthesis high-temperature and high-pressure reaction kettle of the present invention: The threaded connection is used for fastening between them, and the sealing pin 3 is pressed by the kettle cover 2 to realize the conical surface sealing between the sealing pin 3 and the kettle body 1.

[0009] What is disclosed above is only a preferred embodiment of the present invention, and of course it cannot limit the scope of rights of the present invention. Therefore, equivalent changes made according to the patent scope of the present invention still fall within the scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com