Locking device and method

A locking device and lock tongue technology, which is applied in the direction of building fastening devices, wing leaf fastening devices, buildings, etc., can solve the problems of loss of expected locking performance, poor shielding and sealing of electrical cabinet doors, and high assembly requirements. It achieves the effect of eliminating the unsatisfactory deformation and locking of the device, reducing the difficulty of design and manufacturing, and clear and concise external interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred mechanism and motion realization method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

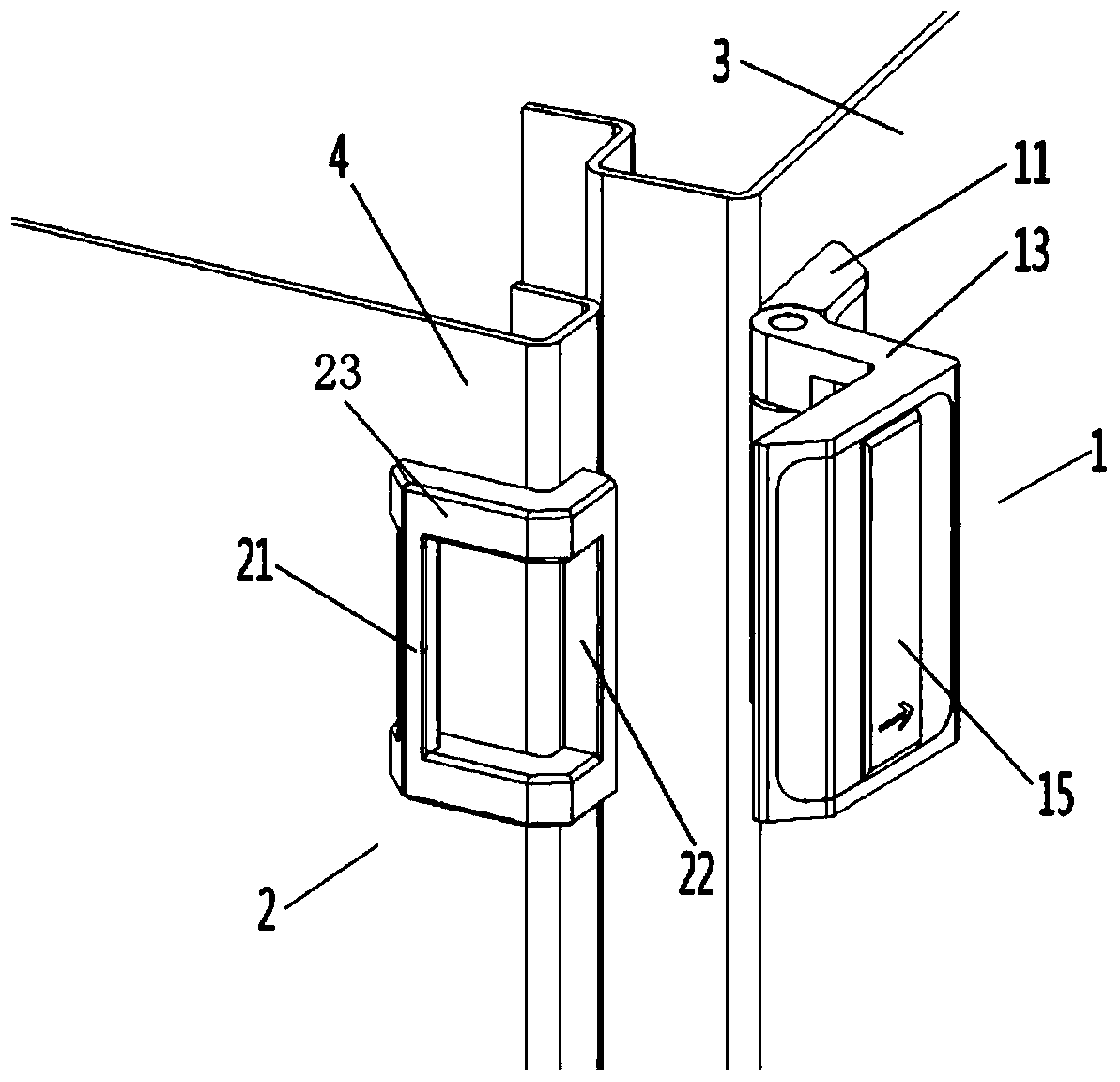

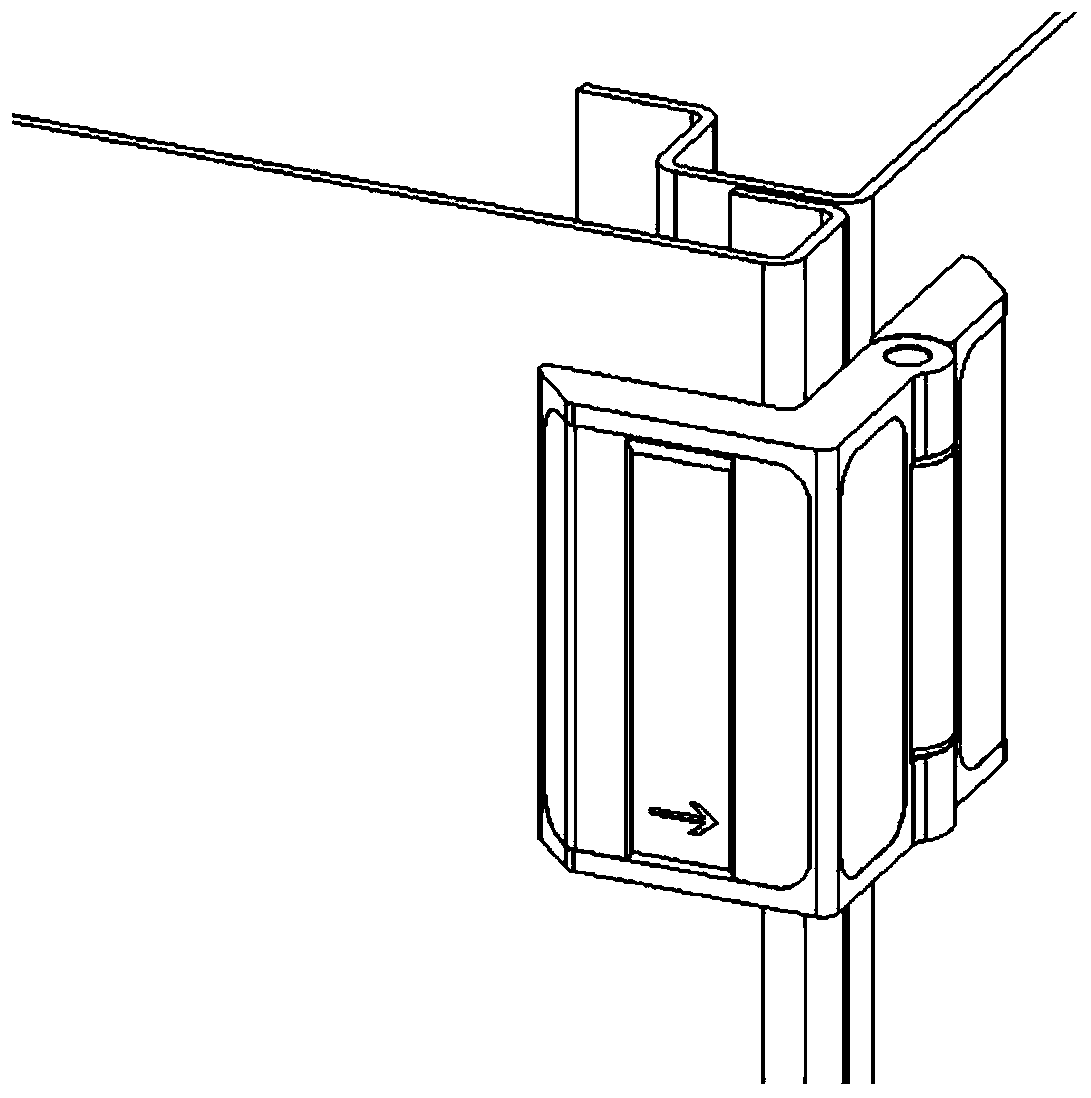

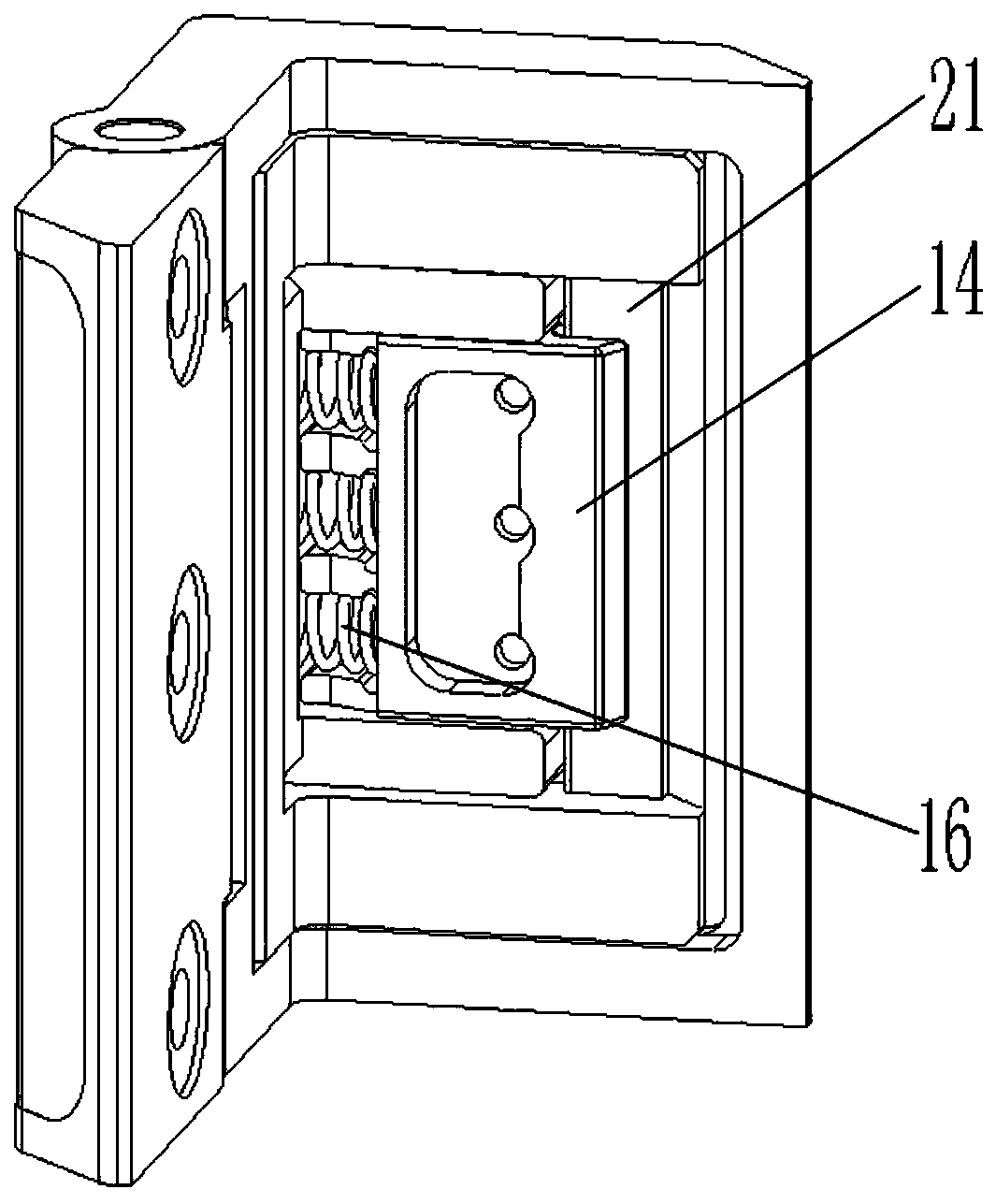

[0030] Such as Figure 1-5 As shown, a locking device includes a lock body 1 and a lock hook 2, the lock body 1 is installed on the door frame 3 of the electrical cabinet, and the lock hook 2 is installed on the cabinet door 4 of the electrical cabinet.

[0031] Wherein, the locking hook 2 is one piece, including a main locking hook 21 and a secondary locking hook 22 , and the two ends of the main locking hook 21 and the secondary locking hook 22 are respectively connected by two L-shaped connecting rods 23 . The L-type connecting rod 23 is arranged horizontally along the outer surface of the cabinet door 4, and the corresponding main lock hook 21 is installed on the front of the cabinet door 4 in a vertical state, and the auxiliary lock hook 22 is installed on the side of the cabinet doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com