Full-automatic mechanical-type book bagging machine and bagging method thereof

A mechanical and fully automatic technology, applied in automatic control of packaging, packaging, labeling machines, etc., can solve the problems of high working noise, difficulty in use and maintenance, etc., to reduce working noise, save packaging paper, and facilitate use and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

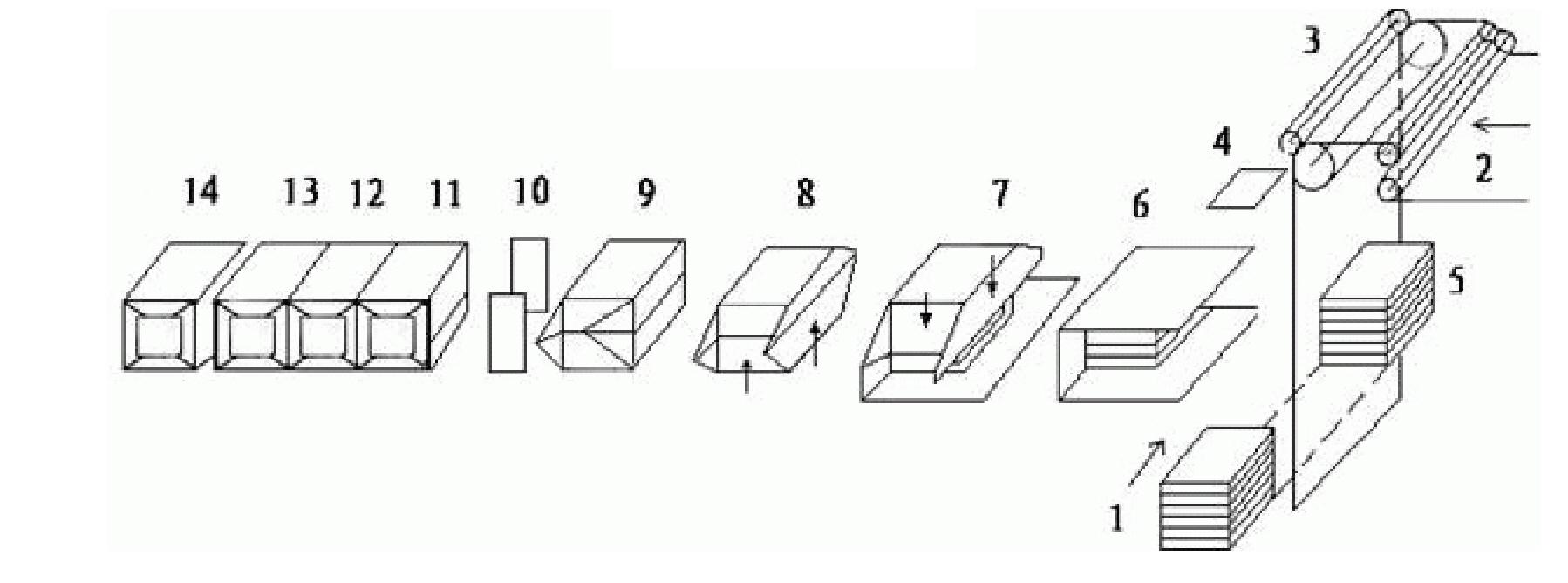

[0053] Such as figure 1 , mechanical full-automatic book packing method of the present invention, comprises the following steps according to the station sequence of technological process:

[0054] Side feeding book—guiding paper—paper feeding—glue dispensing and paper breaking—push book forward—making barrel—front opening of bag and making upper and lower corners—sweeping front side corner—packing—dotting side glue—sticking seal—baking dry—out Bag.

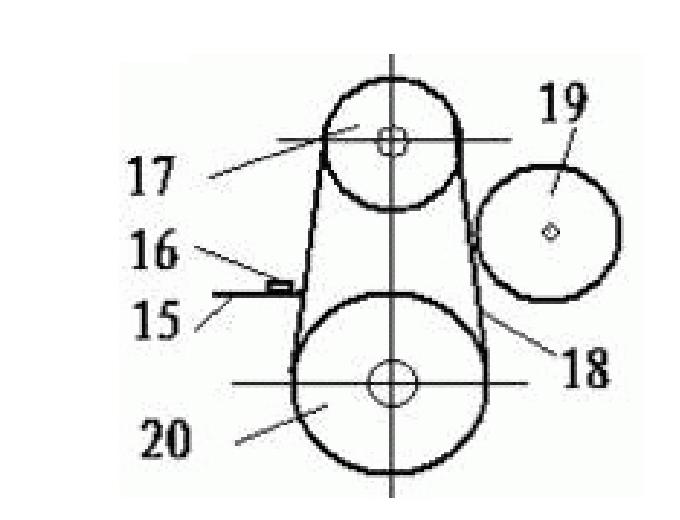

[0055] The side-entry book process is located at station 1. Station 1 is equipped with a side pushing book device, such as image 3 , the structure of the side pushing book device is to include the side pushing book board 15, the side pushing book board 15 is fixedly connected to the chain link of the chain 18, the chain 18 is arranged around the sprocket A17 and the sprocket C20, the chain 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com