Novel rubber protective wax

A technology of rubber protective wax and paraffin wax, which is applied in the field of rubber protective wax to achieve the effect of increasing speed, improving flexibility and viscosity, and reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

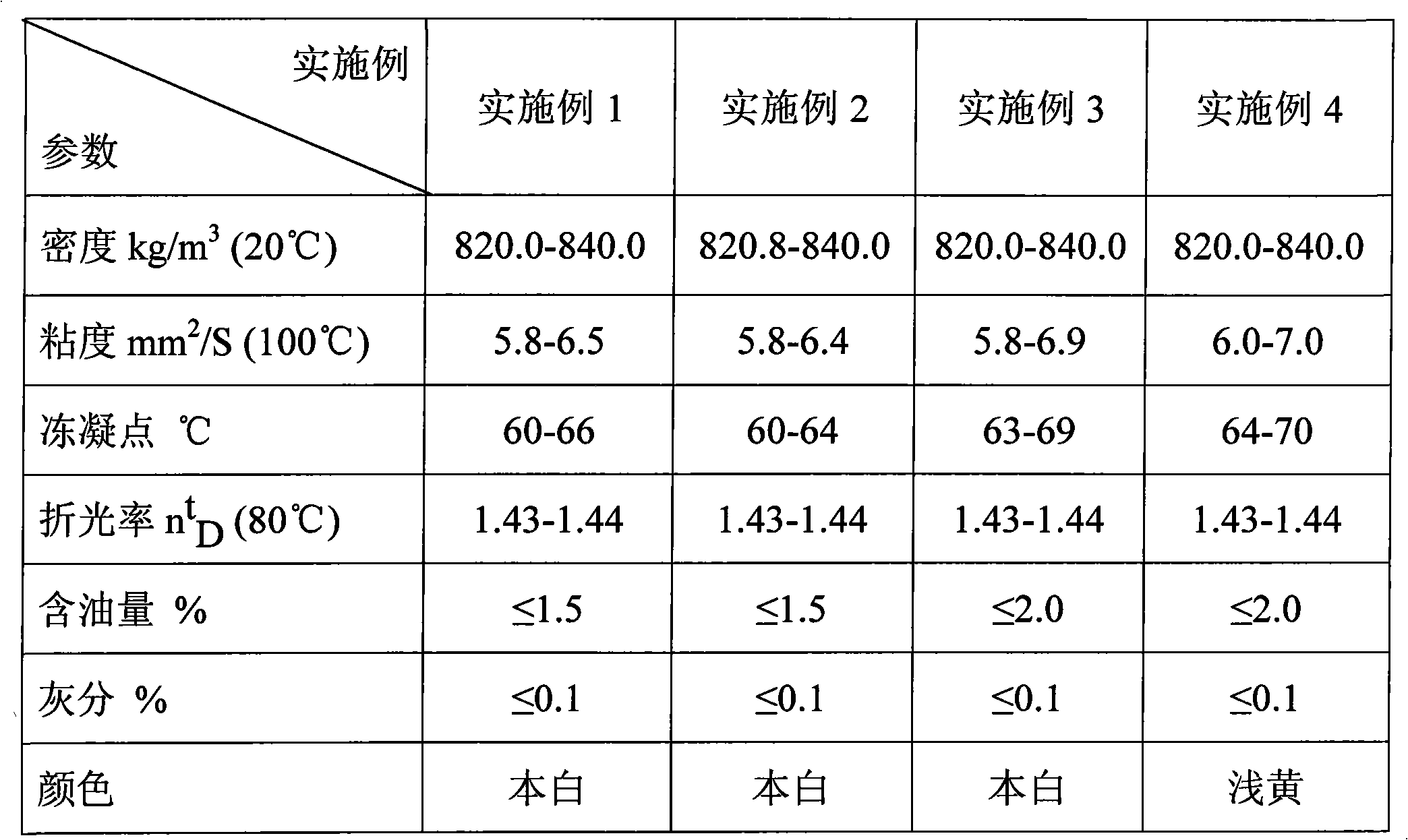

Examples

Embodiment 1

[0021] A kind of rubber protective wax, which contains components and the weight percentage of each component: 15% of paraffin wax, 56% of mixed crystal wax, 28% of microcrystalline wax, and 1% of polyethylene wax.

[0022] Wherein, the fusing point of described paraffin is 60 ℃; The content of normal paraffin in this paraffin is 72%, and the content of non-normal paraffin is 27.5%, also comprises 0.5% non-hydrocarbon substance (such as nitrogen, sulfur or trace metals such as oxygen).

[0023] The melting point of the mixed crystal wax (intermediate wax) is 70°C; the non-normal paraffin content in the mixed crystal wax is 38%.

[0024] The melting point of the microcrystalline wax is 85°C; the non-normal paraffin content in the microcrystalline wax is 59%.

[0025] The molecular weight of described polyethylene wax is 2500.

Embodiment 2

[0027] A kind of rubber protective wax, which contains components and the weight percentage of each component: 17% of paraffin wax, 57% of mixed crystal wax, 24% of microcrystalline wax, and 2% of polyethylene wax.

[0028] Wherein, the melting point of the paraffin is 65°C; the content of normal paraffin in the paraffin is 74%, the content of non-normal paraffin is 25.5%, and it also contains 0.5% of non-hydrocarbon substances.

[0029] The melting point of the mixed crystal wax (intermediate wax) is 74°C; the non-normal paraffin content in the mixed crystal wax is 39%.

[0030] The melting point of the microcrystalline wax is 88°C; the non-normal paraffin content in the microcrystalline wax is 59.5%.

[0031] The molecular weight of described polyethylene wax is 2800.

Embodiment 3

[0033] A rubber protective wax, which contains components and the weight percentage of each component are: 16% of paraffin wax, 58% of mixed crystal wax, 24.5% of microcrystalline wax, and 1.5% of polyethylene wax.

[0034] Wherein, the melting point of the paraffin is 58° C.; the content of normal paraffins in the paraffin is 73%, the content of non-normal paraffins is 26.5%, and 0.5% of non-hydrocarbon substances are also included.

[0035] The melting point of the mixed crystal wax (intermediate wax) is 72°C; the non-normal paraffin content in the mixed crystal wax is 38.5%.

[0036] The melting point of the microcrystalline wax is 82°C; the non-normal paraffin content in the microcrystalline wax is 60%.

[0037] The molecular weight of described polyethylene wax is 2300.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com