Winding machine

A winding machine and winding rod technology, which is applied in the field of winding machines, can solve the problems of high wire cost, poor product uniformity, and high defect rate, and achieve the effects of reducing labor intensity, improving production efficiency, and uniform tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

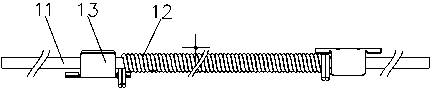

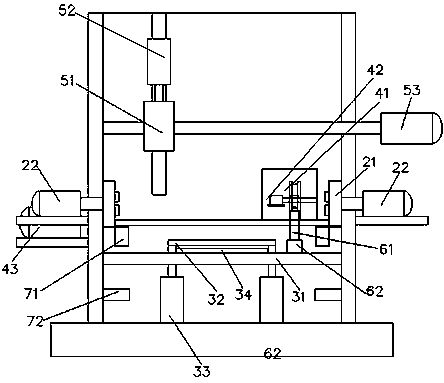

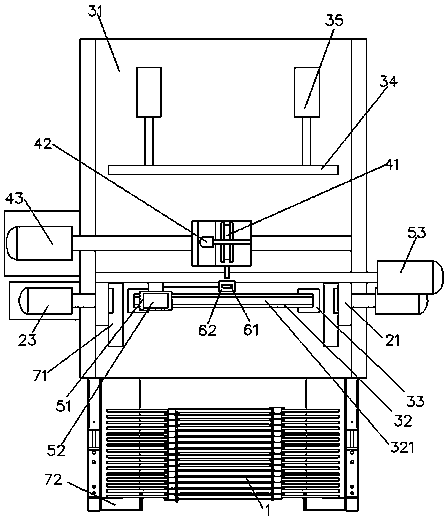

[0030] see Figure 1-Figure 4 , as shown in the legend therein, a winding machine is used to wind the wire 12 on the winding rod 11 and make the wire clamp 13 clamp the wire 12 to form the spring wire rod 1 on the winding rod 11, the above The wire winding machine includes a winding reel mechanism, a rod advancing mechanism, a wire releasing mechanism, a clamping mechanism, a cutting mechanism, a retracting rod mechanism and a control device.

[0031] The above-mentioned reel mechanism includes a symmetrically arranged reel, which includes a clamping disc 21 for clamping the reel rod, a first coil for axially moving the clamping disc 21 Wire driving device (not shown in the figure) and a second winding driving device 22 for making the clamping disc 21 rotate circumferentially; the clamping disc 21 is provided with a clamping hole extending along its axial centerline 211 and several advancing and retreating rod grooves 212 extending radially and communicating with the clamping...

Embodiment 2

[0050] The rest is the same as the above-mentioned embodiment 1, the difference is that the above-mentioned winding machine also includes a chassis, and the above-mentioned winding reel mechanism, rod-entry mechanism, wire-paying mechanism, clamping mechanism, cutting mechanism and retracting rod mechanism are built into the chassis; The above-mentioned control device is placed outside the chassis.

[0051] The setting of the chassis can make the winding be carried out in a confined space, and there will be no potential safety hazard.

Embodiment 3

[0053] The rest is the same as that of Embodiment 2, the difference is that the above-mentioned winding machine also includes a winding rod warehouse for storing multiple winding rods and a wire clip warehouse for storing multiple wire clips, and the wire clip warehouse is set There is a screw feeding mechanism for moving the wire clamp to the clamping manipulator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com