Pony roll cutter

A technology of slitting machine and paper tray, which is applied in metal processing and other fields, can solve the problems of low cutting speed, uneven surface of paper tray, high price, etc., and achieve the effect of improving work efficiency, flat surface of paper tray, and uniform tightness

Inactive Publication Date: 2012-05-02

苏州市乾丰造纸机械制造有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing domestic slitters generally have a slitting speed below 600 m / min, while the imported slitting machines have a maximum slitting speed of 1000 m / min and are expensive

At present, most of the existing slitters have low slitting speed, the surface of the paper rewinding after slitting is not smooth enough, the tightness of rewinding the paper is uneven, and the cutting speed directly affects the efficiency. The basic reason why the traditional slitting machine has a low slitting speed is that the control of the web tension is not stable enough during unloading and rewinding, which leads to low slitting speed and low quality of slitting and rewinding coil paper. , thus causing inconvenience to users in use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

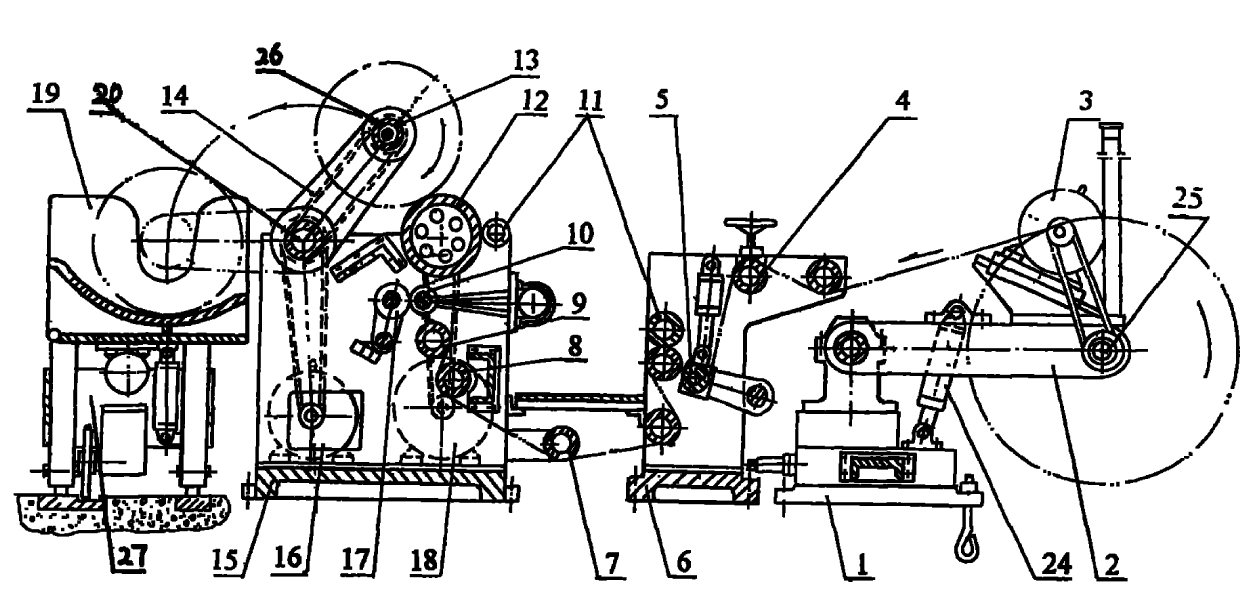

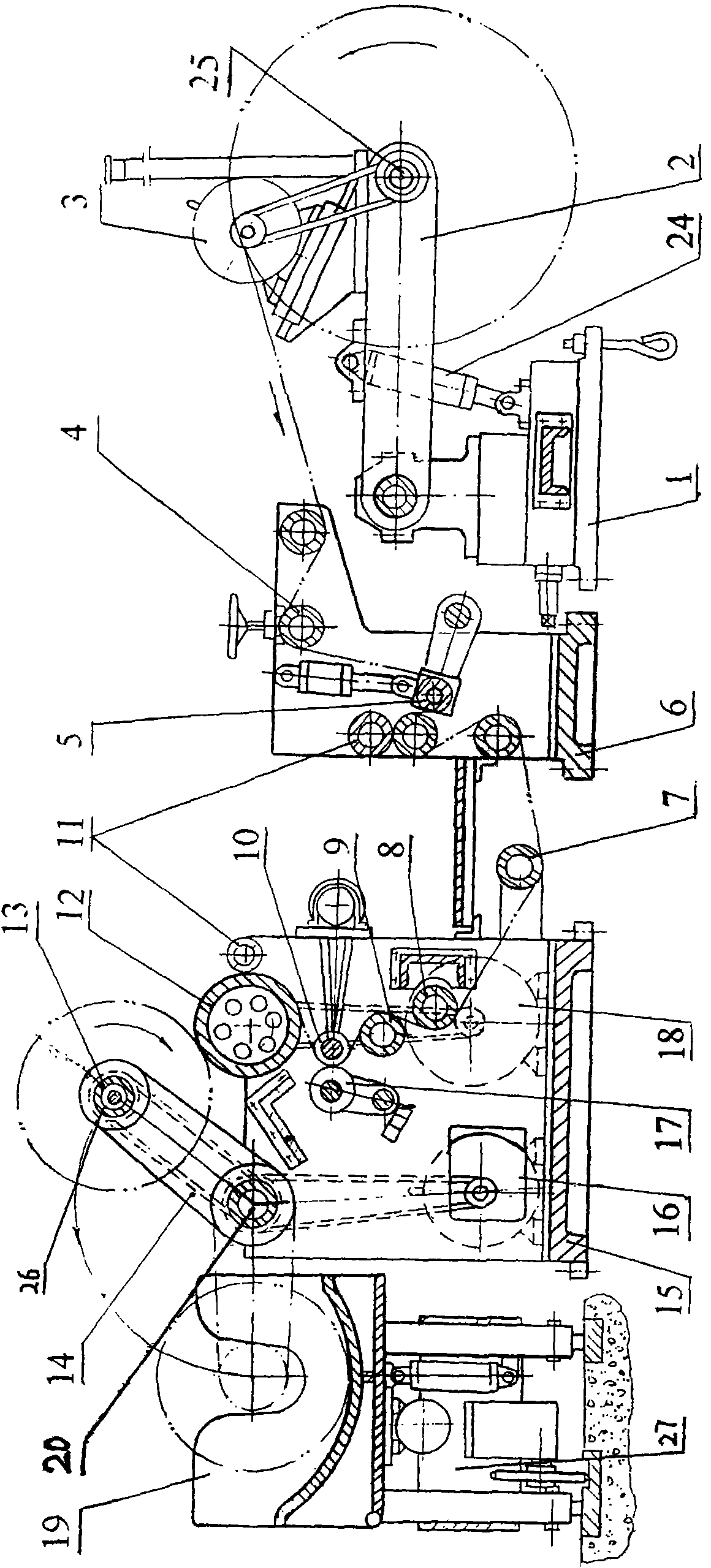

The invention relates to a pony roll cutter, which comprises a paper placing frame and a rewinding frame. A paper placing swinging arm, a paper placing motor, an unwinding top, and an unwinding lift cylinder are arranged on the paper placing frame; a middle trolley frame is arranged on the left of the paper placing frame; and an offset adjusting roller, a buffer roller and a non-return roller arearranged on the middle trolley frame. The rewinding frame is arranged on the left of the middle trolley frame; a pressure roller, an upper slitter, a lower slitter, a paper guiding roller, a paper guiding roller, and a paper unfolding roller are arranged on the rewinding frame respectively; a rewinding motor and a motor for driving the pressure roller are arranged on the rear part of the rewinding frame; a rotating arm shaft, a rewinding swinging arm, and a rewinding shaft are arranged on the upper part of the rewinding frame; and a paper discharging trolley is arranged on the left of the rewinding frame. The pony roll cutter has the advantages of realizing automatic discharge and bobbin splitting, labor conservation, improvement of working efficiency, flat rewound bobbin surface, uniformcompactness, and high-speed slitting and rewinding.

Description

technical field The invention belongs to mechanical processing equipment, and is mainly used for a coil paper cutting machine for cutting and processing paper or other soft and thin materials. Background technique Coil slitters are currently widely used in the cigarette industry, power capacitor production industry, and food packaging industries. As we all know, the higher the cutting speed of the slitter, the higher the production efficiency. The existing domestic slitting machines generally have a slitting speed below 600 m / min, while the imported slitting machines have a maximum slitting speed of 1000 m / min and are expensive. At present, most of the existing slitters have low slitting speed, the surface of the paper rewinding after slitting is not smooth enough, the tightness of rewinding the paper is uneven, and the cutting speed directly affects the efficiency. The basic reason why the traditional slitting machine has a low slitting speed is that the control of the we...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B26D1/24B26D7/06B26D7/01B26D7/18

Inventor 刘月起郑守训

Owner 苏州市乾丰造纸机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com