Opening and closing manipulator for bottle blowing machine

A technology of manipulators and bottle blowing machines, which is applied to household components, household appliances, and other household appliances, and can solve problems such as preform deformation, waste products, and affecting preform processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

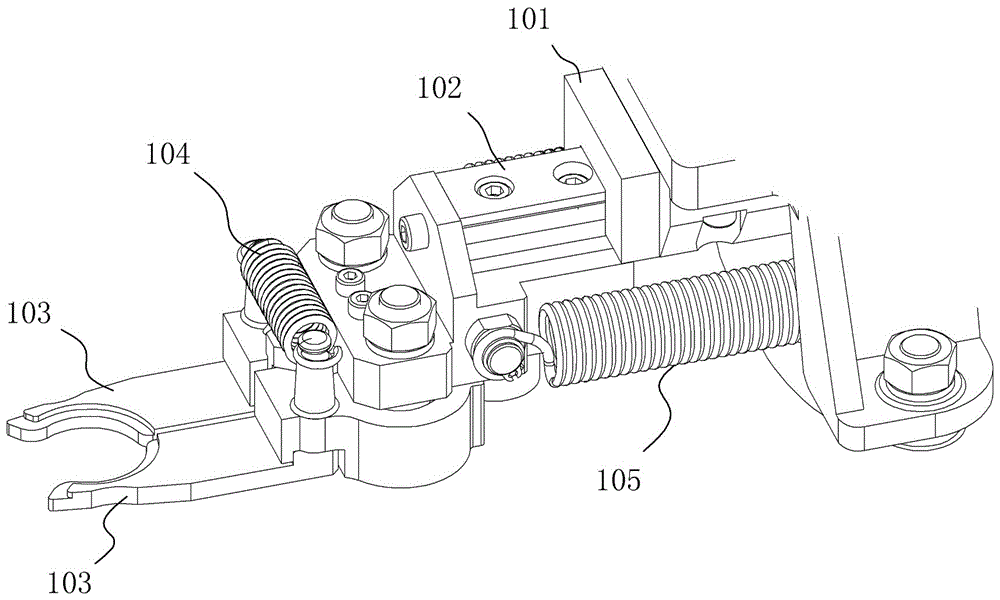

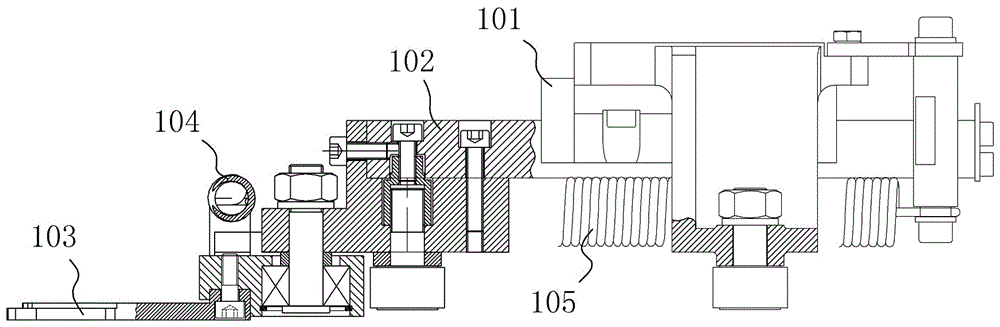

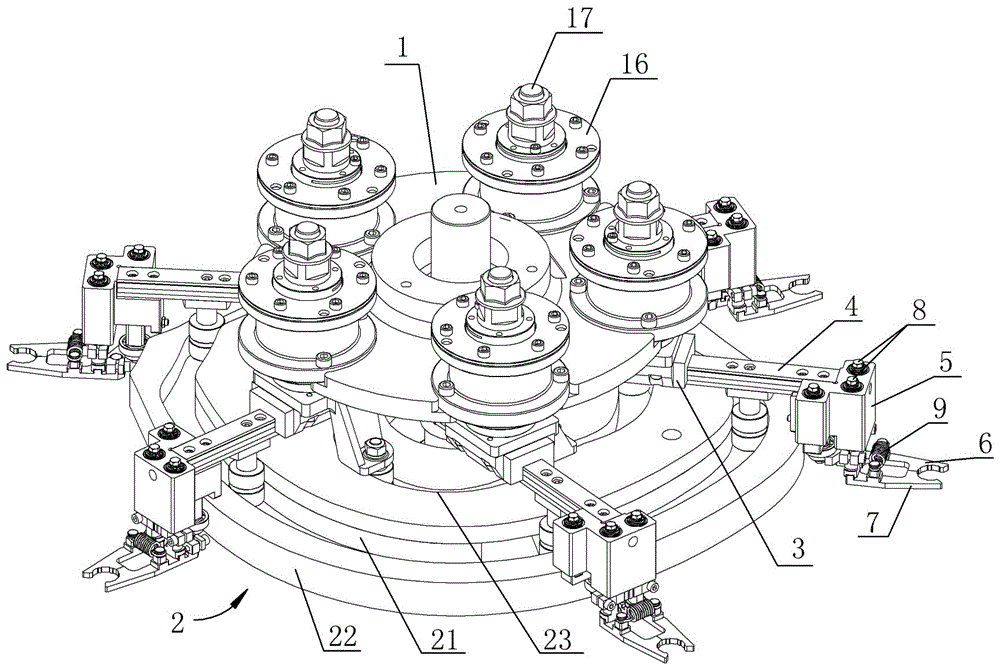

[0013] Such as Figure 1-3 As shown, a bottle blowing machine opening and closing manipulator includes a support plate 1 and a cam plate 2 that rotate around the axis. A number of sliders 3 that rotate with it are installed on the support plate along the circumference. The sliders are equipped with movable The slide rail 4, the end of the slide rail is equipped with the first clamping hand 6 and the second clamping hand 7 through the connecting plate 5; both clamping hands are hinged on the connecting plate through the rotating shaft 8, between the two clamping hands is equipped with The extension spring 9 which rotates oppositely, the two rotating shafts are fixedly equipped with a gear plate 10 with gear teeth and intermeshing, and the first gripper is also fixed with a rotating arm 11; the cam plate is provided with a telescopic cam 21 and an opening Closing cam 22, the telescopic guide wheel 12 that moves along the telescopic cam is housed on the slide rail, the opening an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com