Edge pressing mechanism of high-speed can body stretcher

A stretching machine and edge blanking technology, which is applied to the edge blanking mechanism field of the can body stretching machine, can solve the problems of poor synchronization of the double blank blanking cam drive, inconvenient maintenance, oil and emulsion pollution, etc. Poor performance, avoid sealing difficulties, and simplify the effect of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

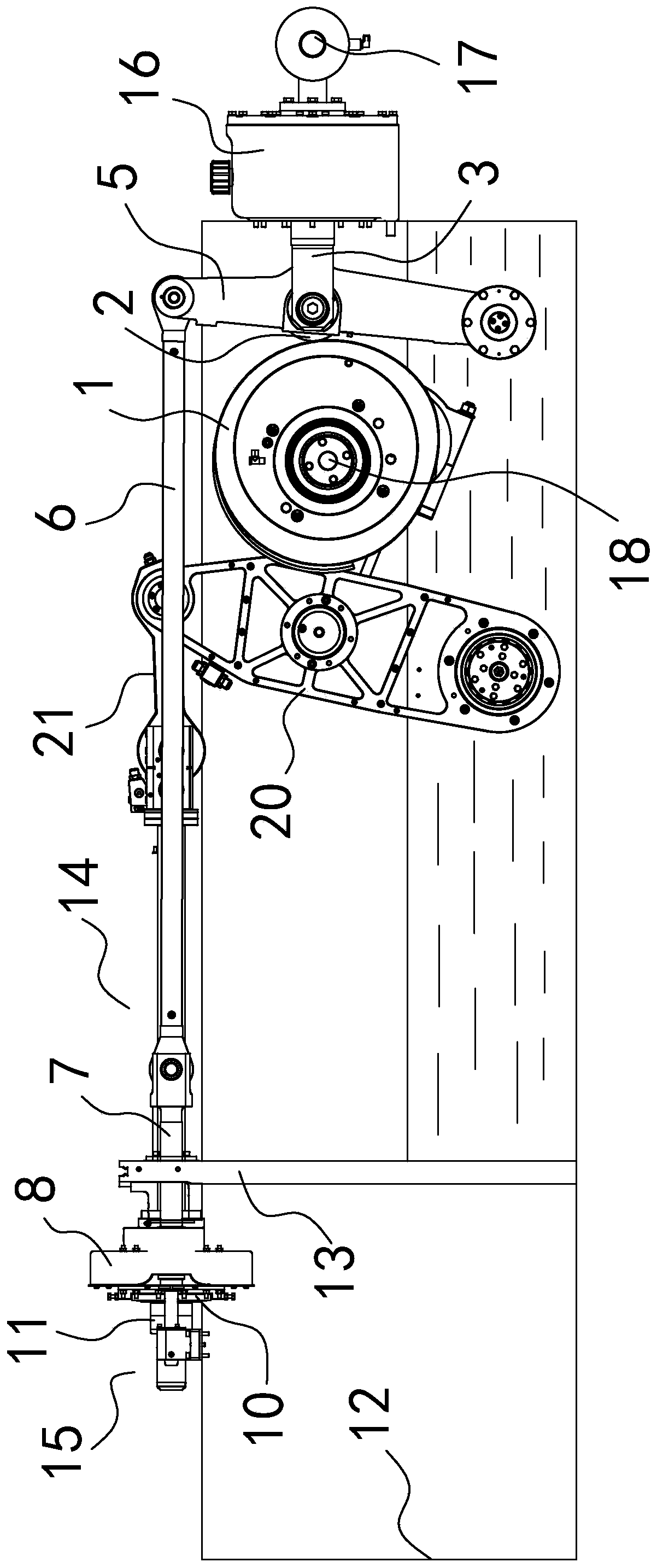

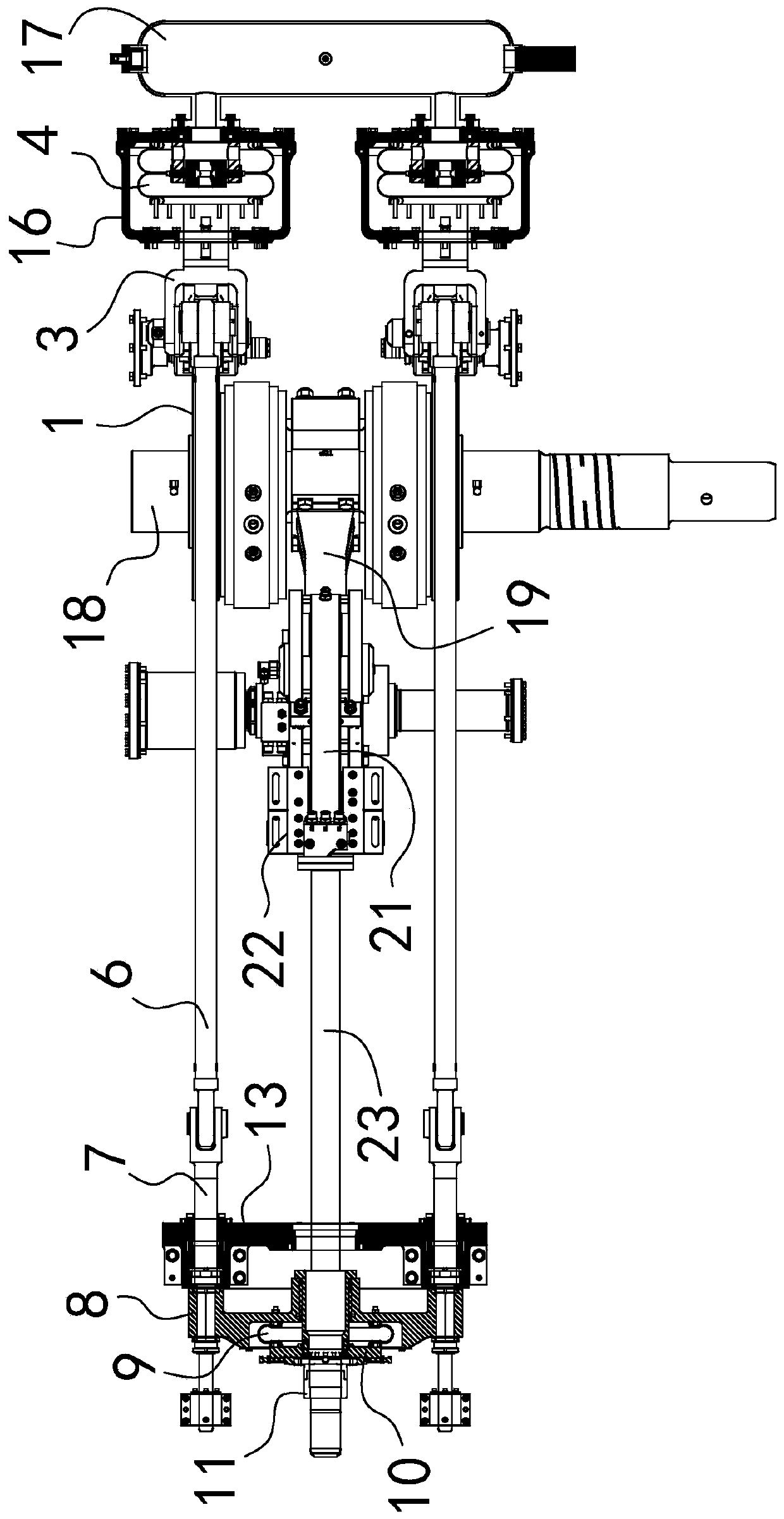

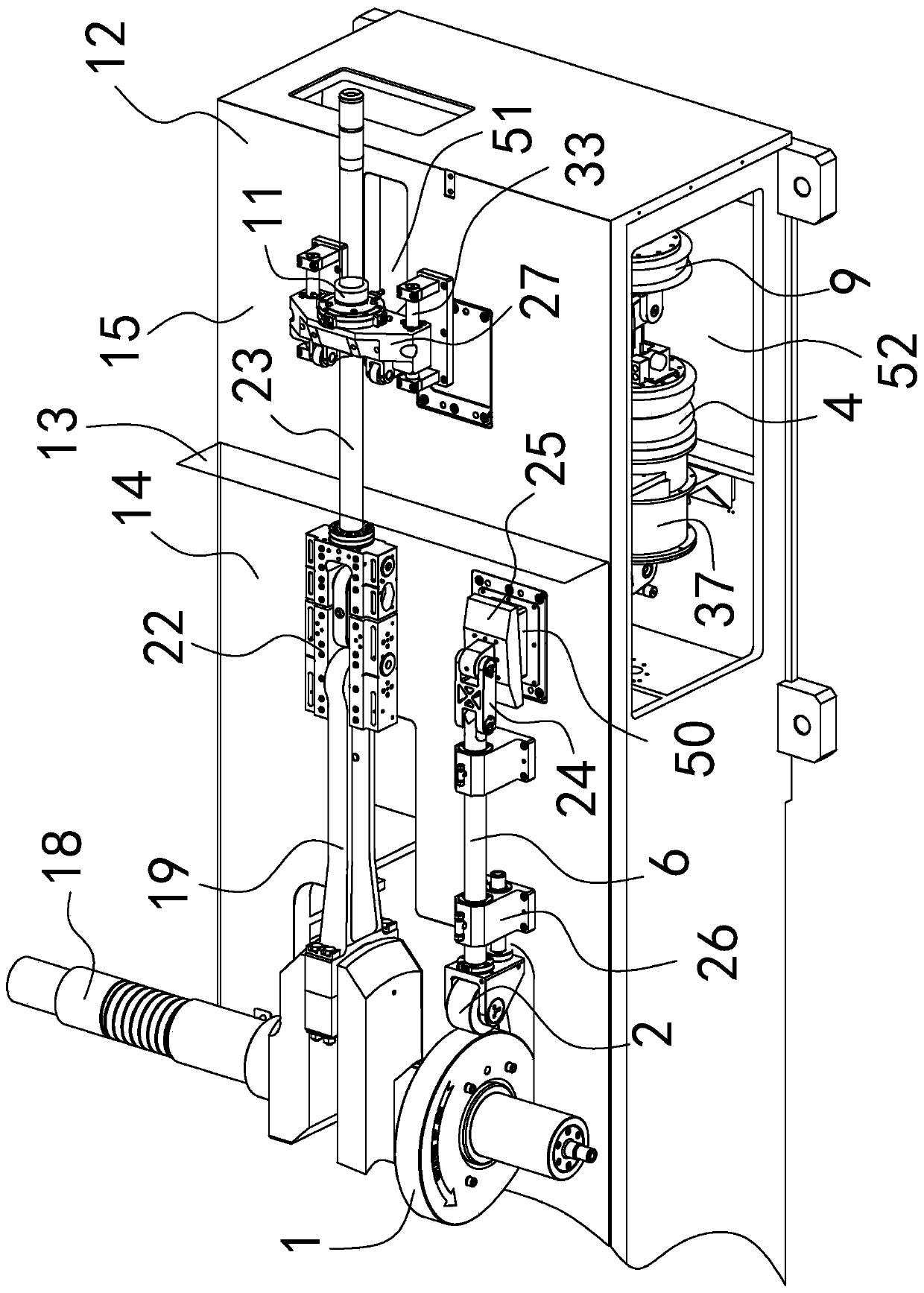

[0062] Embodiment: A blank-holding mechanism of a high-speed can body stretching machine

[0063] Such as Figure 3-Figure 15 As shown, the blank-holding mechanism includes a blank-holding cam 1 (see image 3 , Figure 4 with Figure 7 ), the blanking cam 1 is driven by the crankshaft 18 on the tank body stretching machine, and the crankshaft 18 is rotatably supported relative to the box body 12 of the tank body stretching machine (see image 3 ).

[0064] According to the drive chain from the blankholder cam 1, there are: cam follower 2, blankholder push rod 6, blankholder large connecting rod 24, thrust arm 28, follower rod 35, rear blankholder force arm 29, torque Shaft 31, front blankholder arm 30, blankholder small connecting rod 43, blankholder slider 27 to blankholder sleeve 11 (see Figure 7 ). The parts and structures in the blank holder mechanism are described in turn below:

[0065] A cam follower 2 and a blanking push rod 6 are provided for the blanking cam 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com