Conversion valve

A technology for steering valves and valve bodies, which is applied to valve details, multi-way valves, valve devices, etc. It can solve the problems of unmanufacturable assembly accuracy, rusting, fracture and damage of steering valves, etc., and achieve simple and reliable structure, stable operation, and easy to use Effect of life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

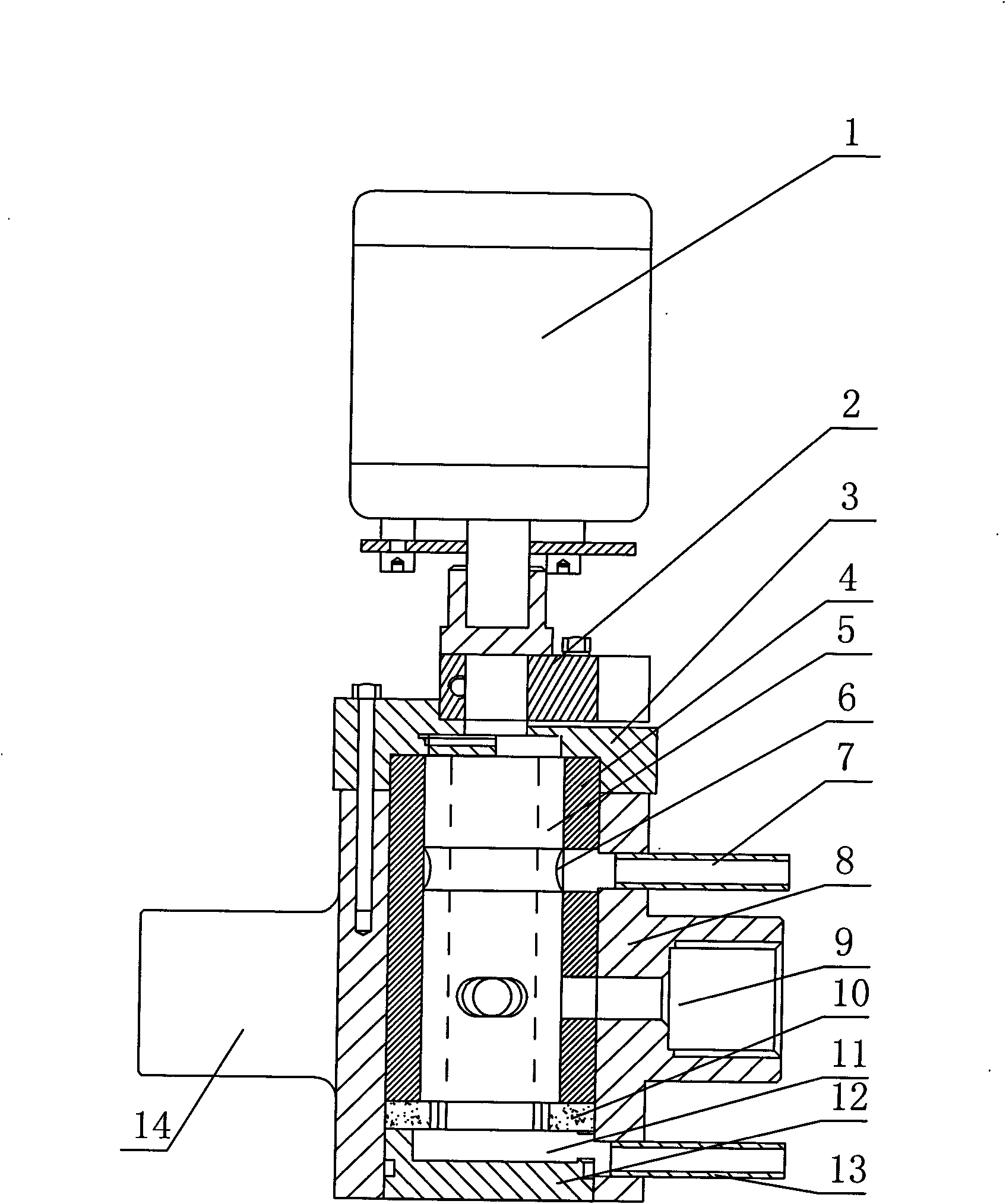

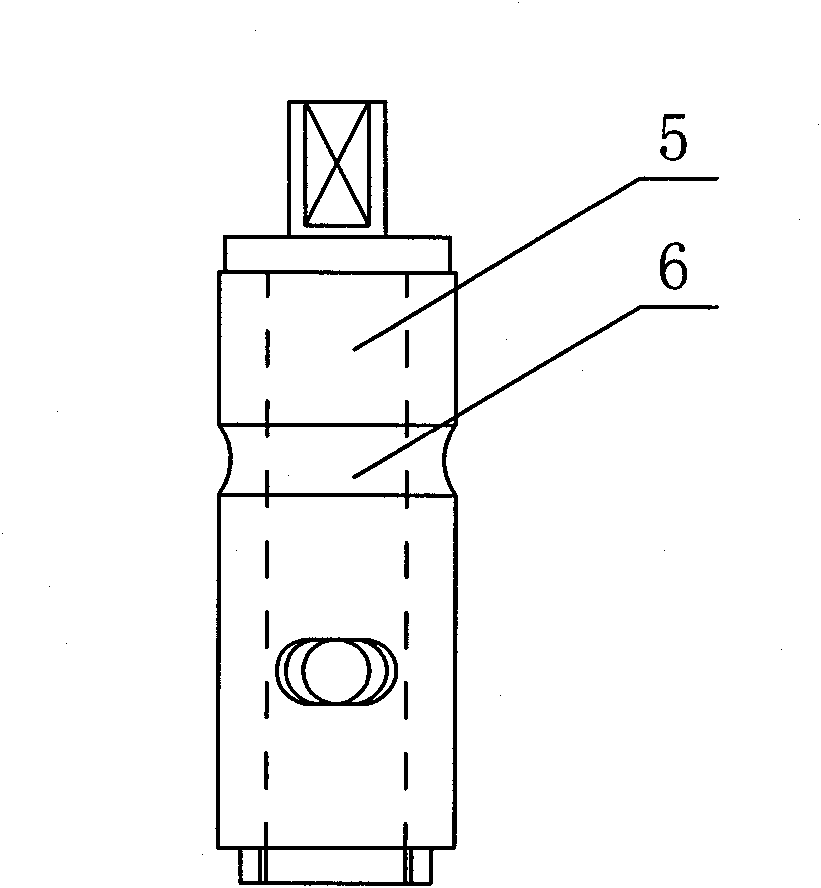

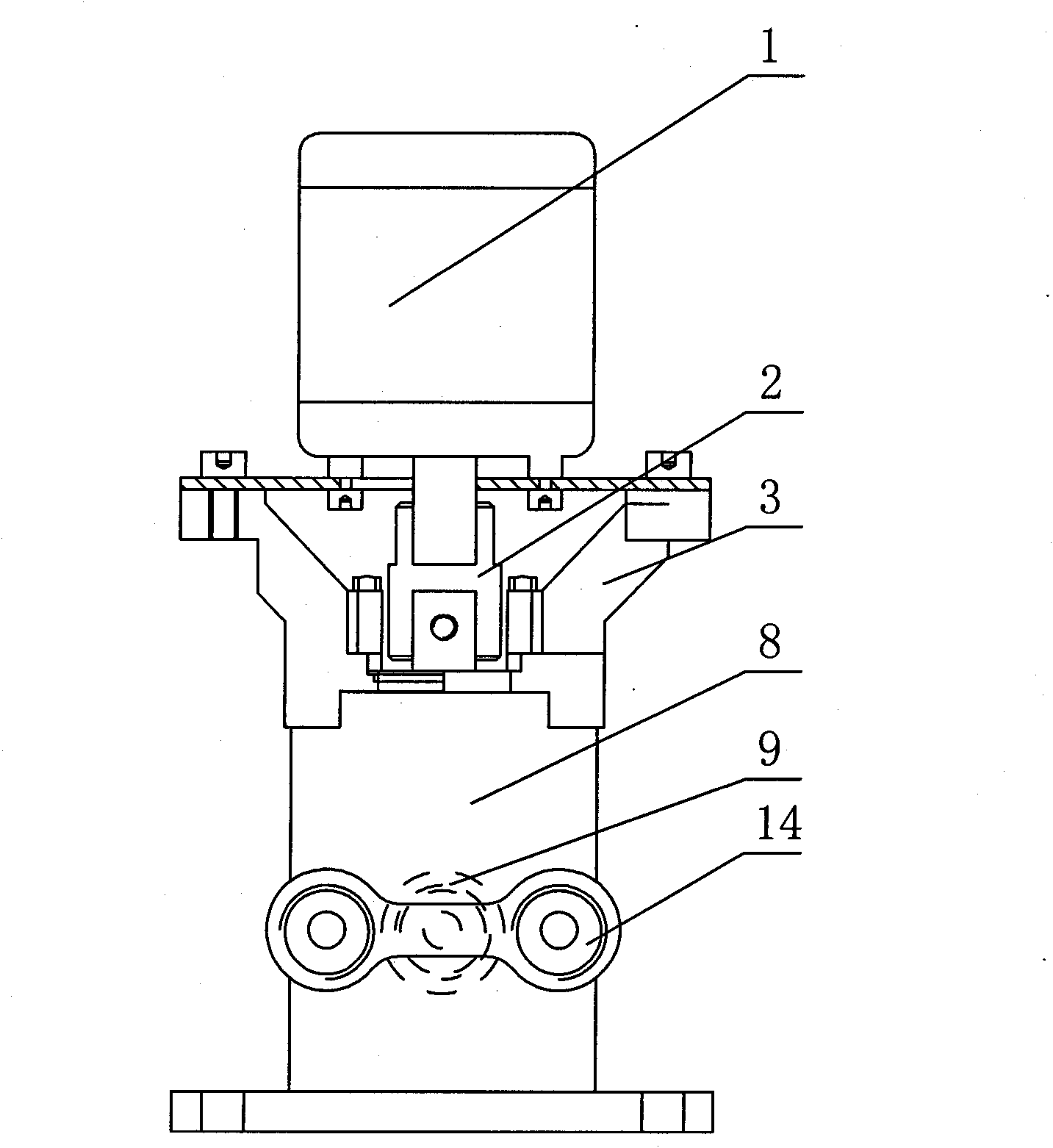

[0016] Such as figure 1 , image 3 As shown, the hollow inner wall of the valve body 8 of the steering valve of the present invention is interference-fitted with a ceramic valve sleeve 4, and the ceramic valve core 5 is interference-fitted on the outer peripheral surface of the stainless steel central shaft, and the top of the stainless steel central shaft is driven by the motor 1. Block 2 is limited; such as figure 2 As shown, the peripheral surface of the ceramic valve core 5 is provided with a ring-shaped recessed water collection tank 6; the small gap between the ceramic valve core 5 and the ceramic valve sleeve 4 is matched, and the unilateral gap is 3-6 μm, preferably 4 μm; the valve sleeve 4 and the valve core 5 are axially positioned through the support of the upper valve cover 3 and the lower positioning tile 10, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com