Automatic grinding fixture for numerical-control machine tool

A CNC machine tool and grinding technology, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of jig hesitation, labor waste, time-consuming and labor-intensive, etc., and achieve the effect of improving detection accuracy, detection accuracy, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

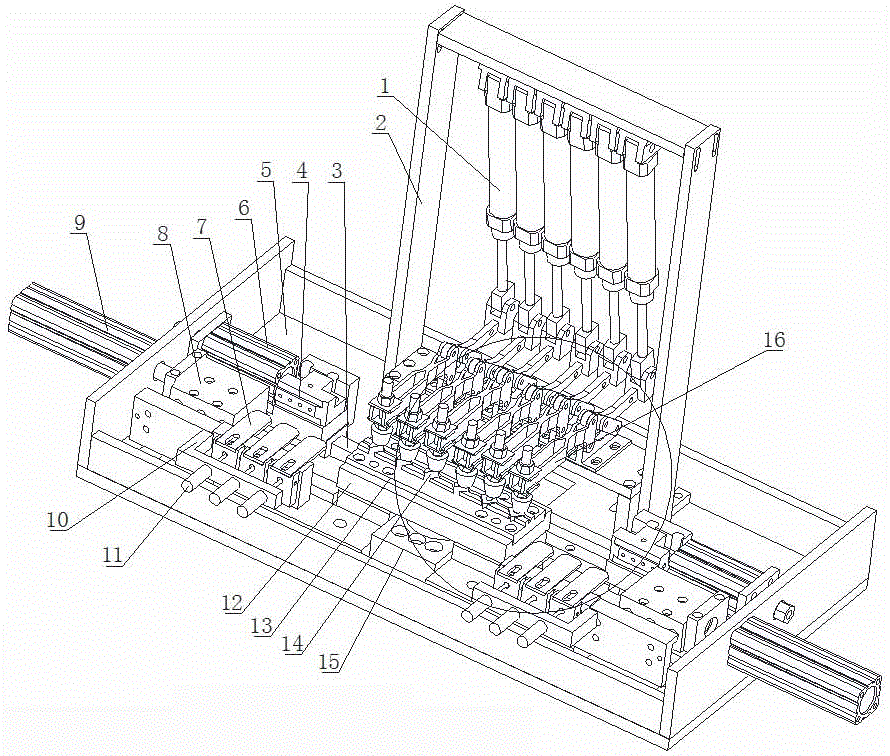

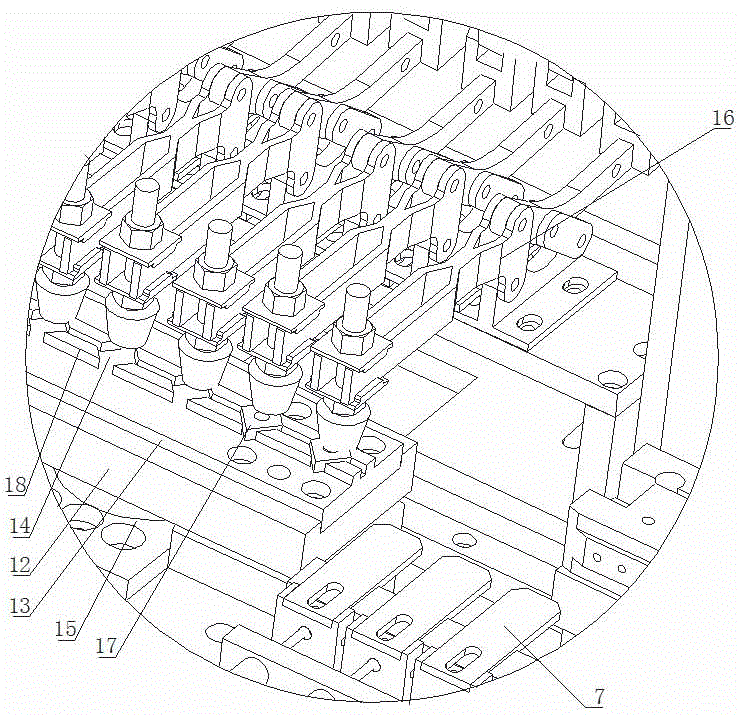

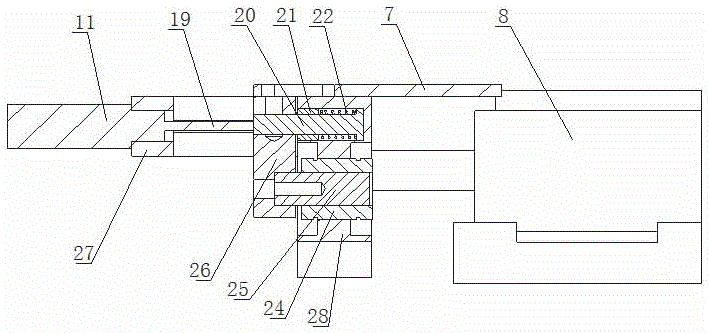

[0018] As shown in the figure, the automatic grinding fixture for CNC machine tools is provided with a mounting plate 5, and the middle part of the mounting plate 5 is provided with a 180° rotary cylinder 15, and the turntable of the rotary cylinder 15 is provided with a mold clamping seat 12, and the mold clamping The seat 12 is provided with a positioning mold, and the positioning mold is provided with a workpiece embedding groove 14; the structure of the positioning mold is: a connecting seat 13 is provided, and the connecting seat 13 is provided with a rectangular positioning plate 18 for installing workpieces to be processed , on the positioning plate 18, a row of open workpiece embedding grooves 14 is uniformly processed longitudinally, and the front and rear sides of the positioning plate 18 are provided with processing openings, from figure 2It can be seen from the figure that the positioning plate 18 is divided into sections by the workpiece embedding groove and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com