Hydraulic device for degassing and dewatering a hydraulic oil

A hydraulic mechanism and hydraulic oil technology, applied in the direction of liquid degassing, liquid degassing adjustment/control, mechanical equipment, etc., can solve the problems of deteriorating lubrication characteristics, surface corrosion, accelerated aging, etc., and achieve high-efficiency degassing and dehydration with low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

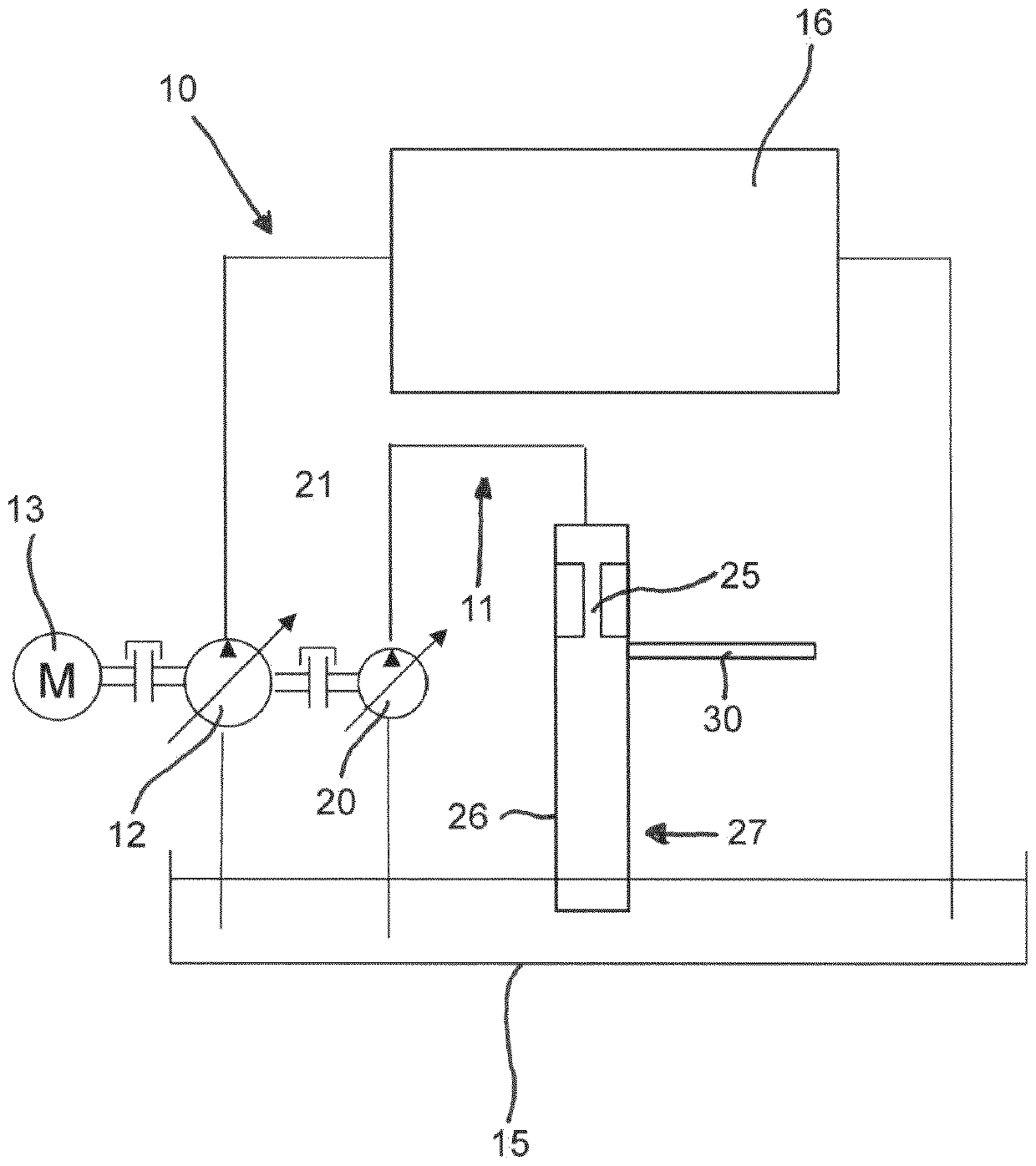

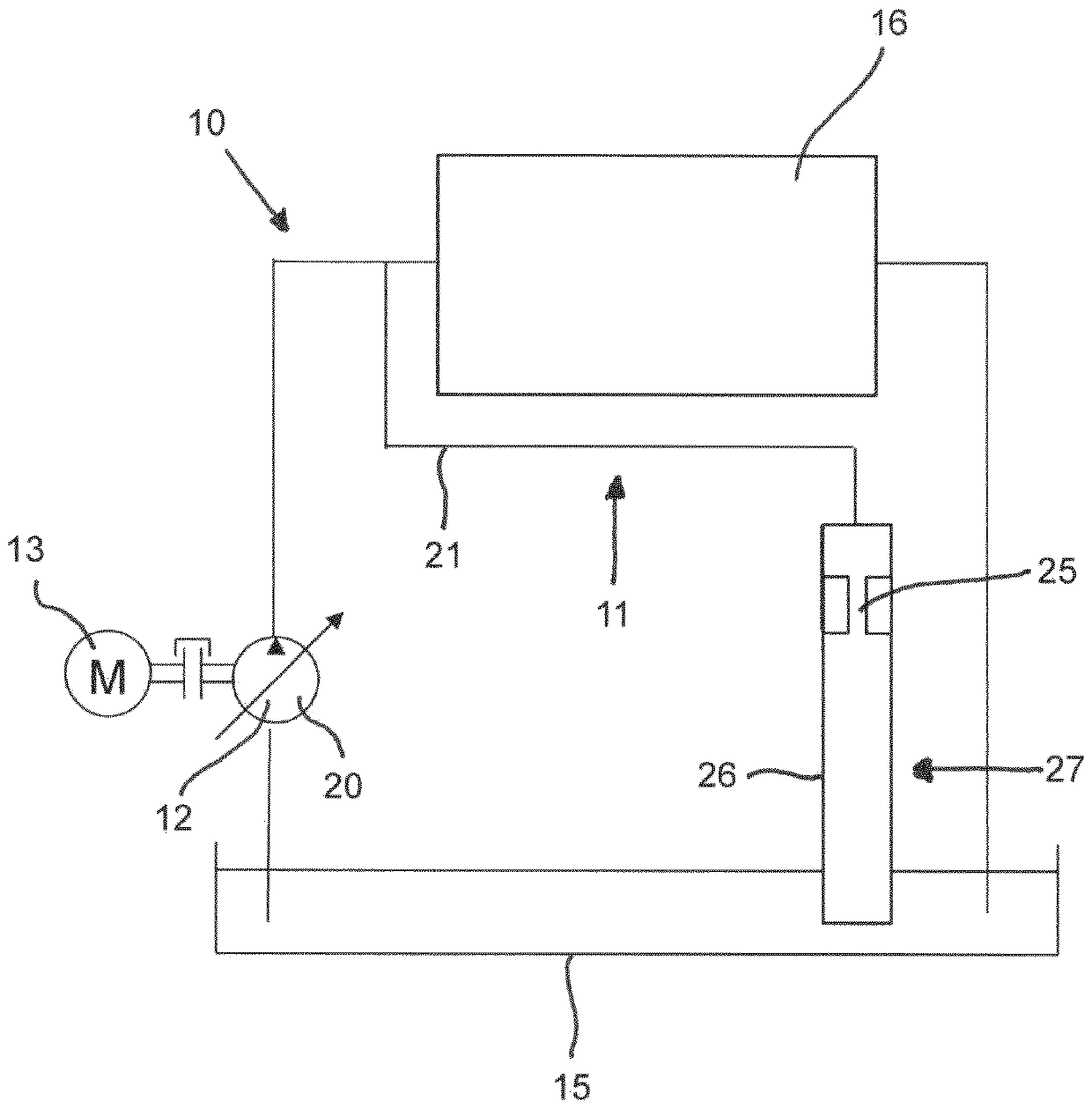

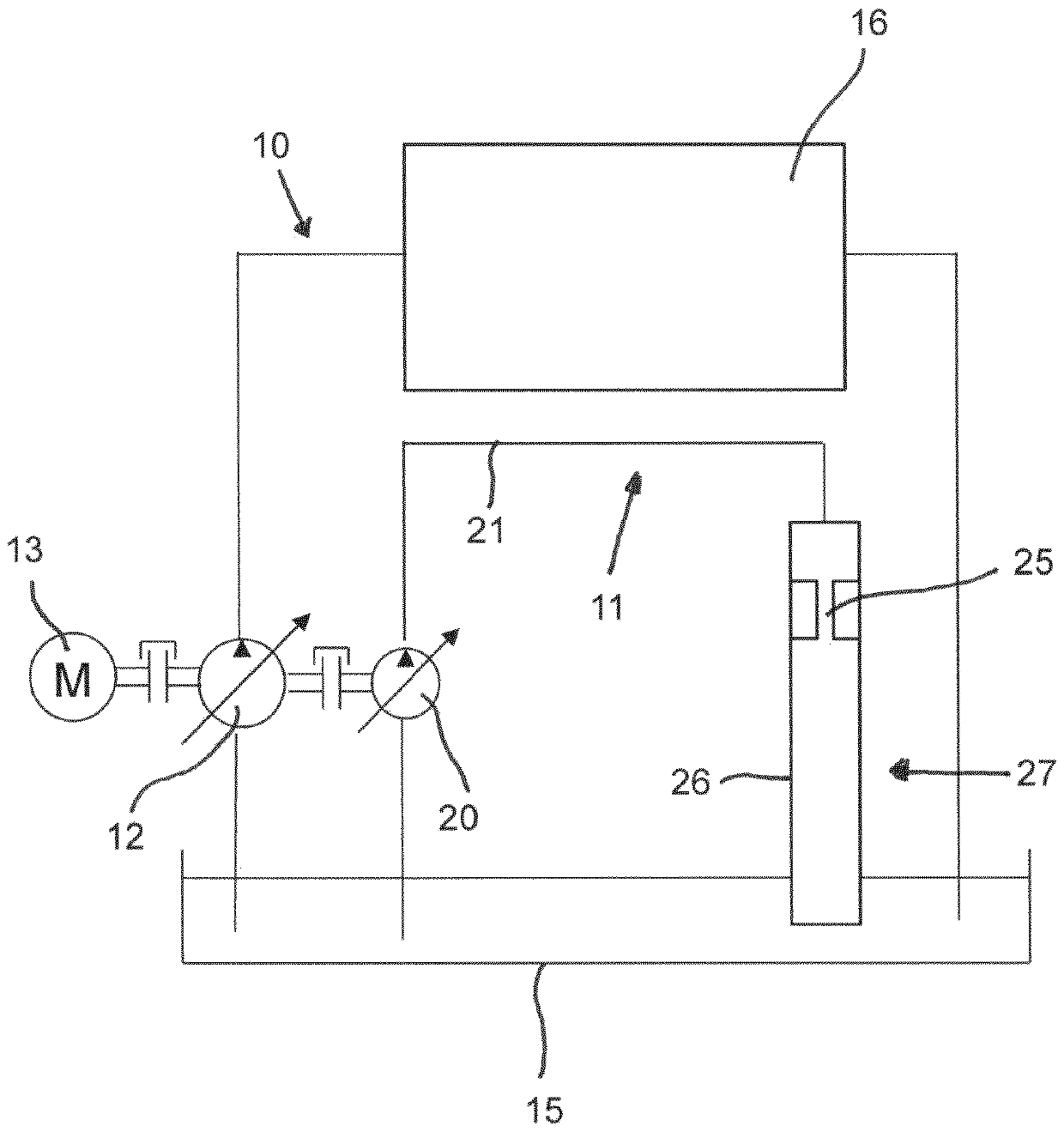

[0033] according to figure 1 The hydraulic equipment includes a hydraulic working circuit 10 and a hydraulic secondary circuit 11, which forms a mechanism for degassing and dehydrating. Belonging to the working circuit 10 is a hydrostatic main pump 12 in the form of a squeezer, which is adjustable in its displacement and which can be driven by a motor 13 , for example an internal combustion engine or an electric motor. If necessary, one or more hydraulic loads are supplied with hydraulic oil by a squeeze pump (Verdränger pump 12 ) via one or more hydraulic valves. The squeeze pump 12 pumps hydraulic oil from a tank 15 to the hydraulic load, into which hydraulic oil flows from the hydraulic load back.

[0034] hydraulic loads and hydraulic valves in figure 1 is shown in a very simplified manner and are collectively assigned the reference numeral 16 .

[0035] The hydraulic secondary circuit 11 is a separate high-pressure circuit and is used for degassing and dehydrating the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com