Intelligent source baffle plate system and method thereof for preparing hard coating

A technology of hard coating and energy, applied in the field of intelligent source baffle system and preparation of hard coating, can solve the problem of reducing the loading space of the coating machine and the loading capacity of the workpiece, the adsorption of the gas cannot be released quickly, and the pollution of the CAE target surface. and other problems, to achieve the effect of reducing the possibility of air leakage and jamming, improving the background vacuum degree and simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

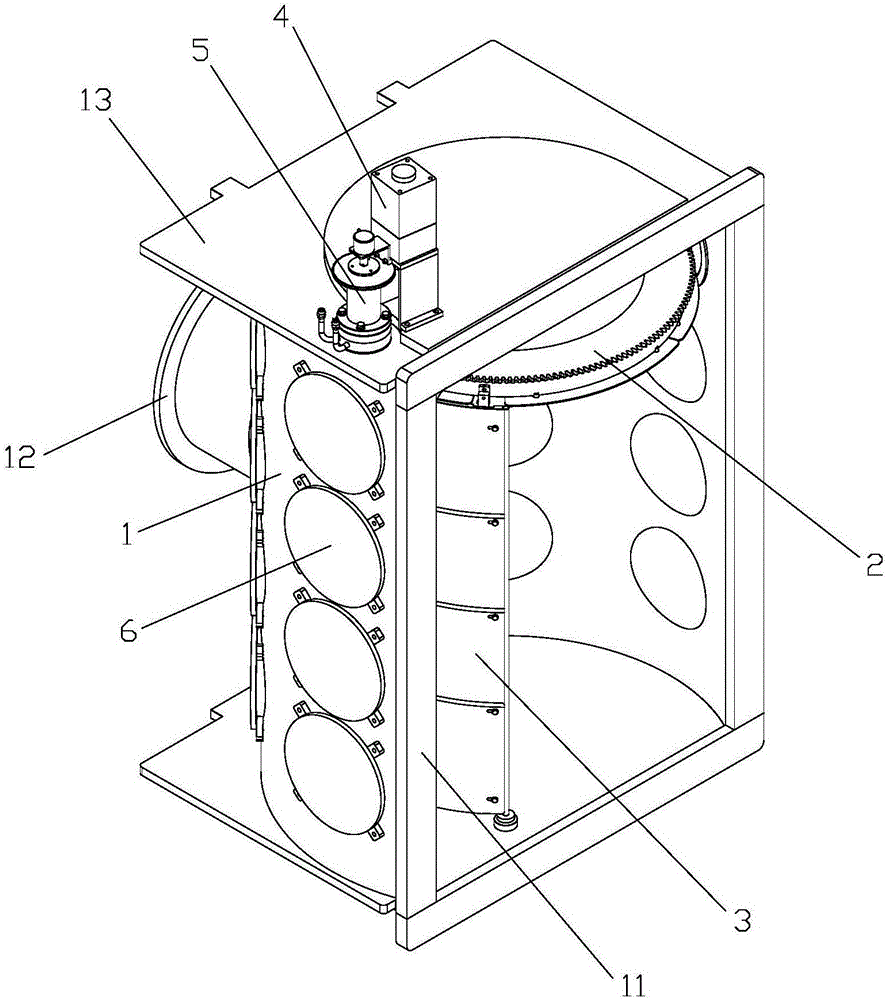

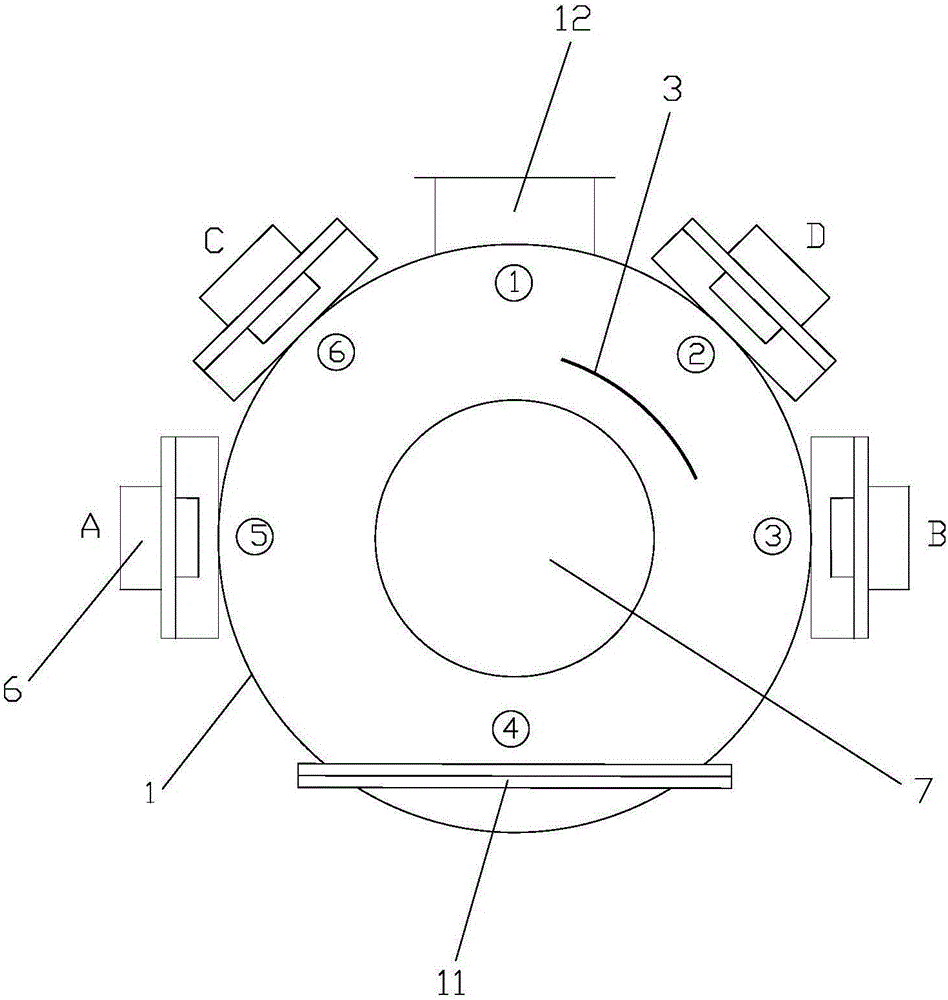

[0051] Such as Figure 1 to 3 As shown, the smart source baffle system of the present invention includes a vacuum chamber 1, a circular gear ring 2, a smart source baffle 3, a gear reduction motor 4, a magnetic fluid seal transmission shaft 5 and a target source 6.

[0052] The vacuum chamber 1 is cylindrical as a whole, with a front door 11 on the front side, a main exhaust port 12 on the rear side, and a top plate 13 on the top; wherein the circumferential side wall of the vacuum chamber 1 is also provided with a number A , B, C, D four groups of cathodic arc target sources (CAE) 6 of the same or different target materials, each group of target sources 6 is composed of four separate target sources.

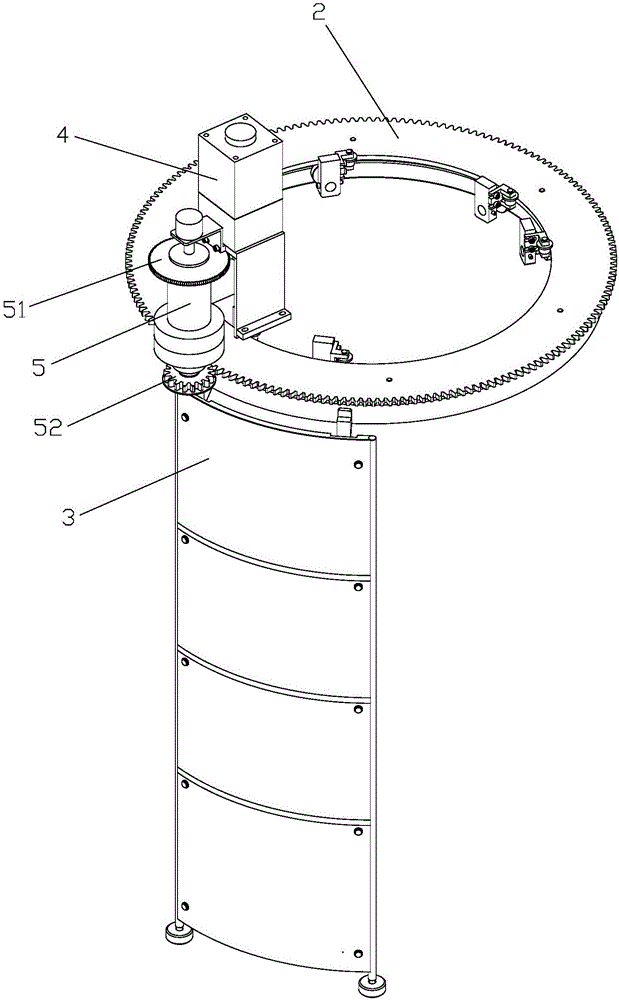

[0053] The circular gear ring 2 is hoisted on the inner side of the top end of the vacuum chamber 1.

[0054] The smart source baffle 3 is hoisted under the circular gear ring 2.

[0055] The gear reduction motor 4 is mounted on the outside of the top plate 13 of the vacuum chamber 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com