Device and method for efficiently dissolving poly(p-phenytene terephthalamide) resin

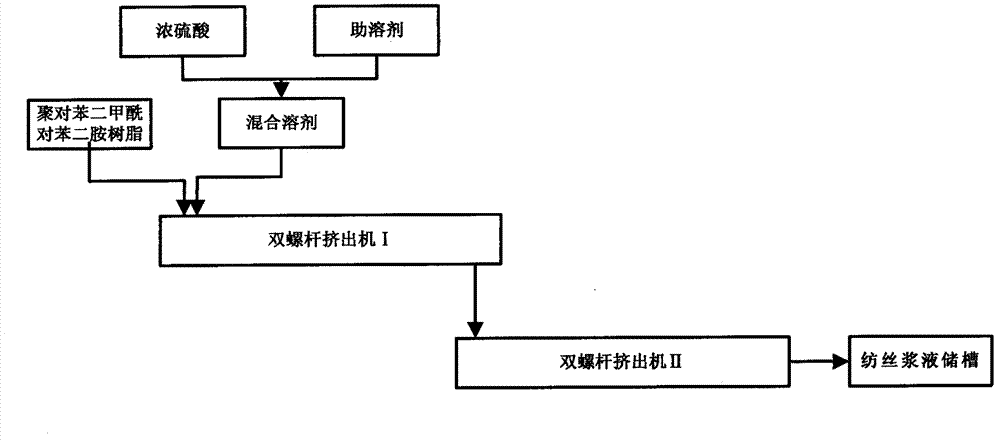

A technology of p-phenylene terephthalamide and poly-p-phenylene terephthalamide is applied in the field of spinning solution preparation of poly-p-phenylene terephthalamide, and can solve the problems of uneven dissolution, limited dehydration capacity, uneven distribution of sulfuric acid and the like , to achieve the effect of improving the dissolution effect, reducing the gel particles and reducing the agglomeration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

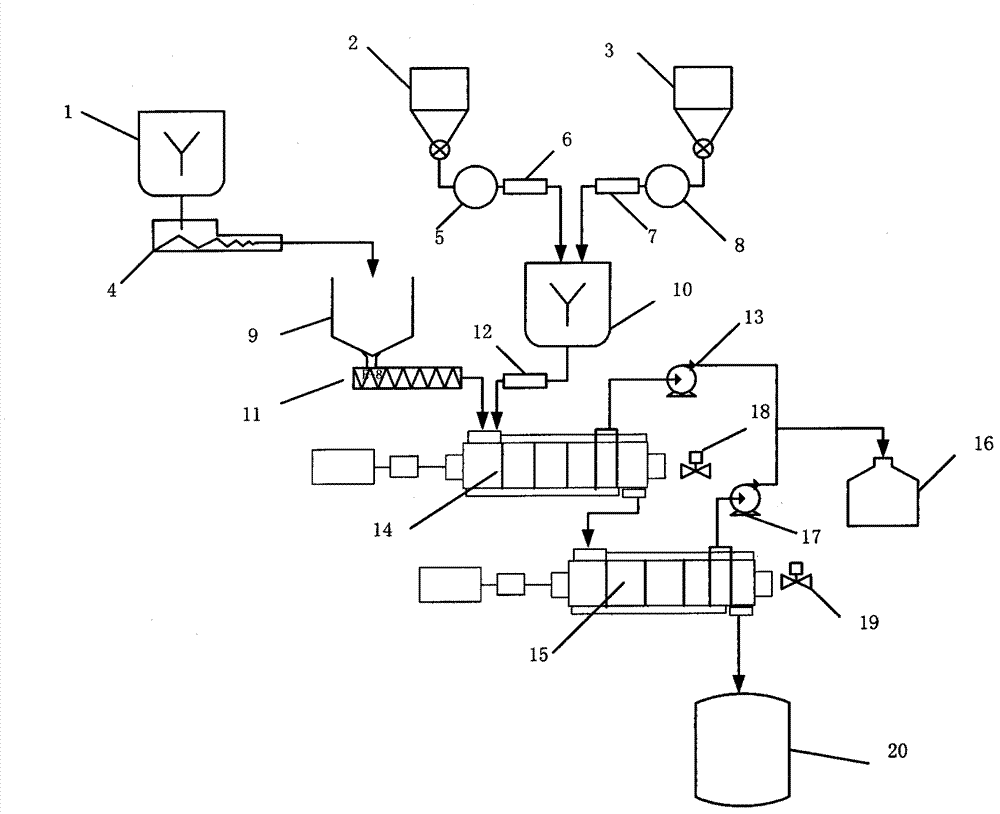

example 1

[0030] Using a liquid mass flowmeter and a high-precision loss-in-weight continuous metering electronic scale, the mixed acid of 99.4% concentrated sulfuric acid and 5% phosphorus pentoxide and polyterephthalamide with a logarithmic viscosity of 6.5dl / g The diamine resin is added with the feed rate of 60.00g / min and 15.00g / min and the diameter is φ125mm, the ratio of length to diameter is 8:1, co-rotating, the temperature of the twin-screw extruder that the rotating speed is 330rpm is 15 ℃, and the residence time is 30min, fully mixed, the extruded material is fed into the introduction area of a twin-screw extruder with a diameter of φ300mm, an aspect ratio of 10:1, co-rotating, and a speed of 70rpm. The temperature is 85°C and the residence time is 20min. The degassing zone of the two extruders is externally connected with vacuum pumping, the vacuum degree is 4KPa, and the pressure in the pressurized zone is 5MPa, and the dissolved slurry is degassed.

[0031] After being m...

example 2

[0033] Using a liquid mass flowmeter and a high-precision loss-in-weight continuous metering electronic scale, the mixed acid of 99.4% concentrated sulfuric acid and 5% perchloric acid and the logarithmic viscosity of 5.6dl / g poly terephthalamide The amine resin is fed into a twin-screw extruder with a diameter of φ125mm, an aspect ratio of 8:1, and a rotation speed of 330rpm at a feeding rate of 60.00g / min and 15.00g / min. The temperature is 15°C and the residence time is 30min. , fully mixed, the extruded material is fed into the introduction area of a twin-screw extruder with a diameter of φ300mm, an aspect ratio of 10:1, co-rotating, and a rotating speed of 70rpm. The temperature is 85°C and the residence time is 20min. The degassing zone of the two extruders is externally connected with vacuum pumping, the vacuum degree is 4KPa, and the pressure in the pressurized zone is 5MPa, and the dissolved slurry is degassed.

[0034]After being metered and filtered, the extruded s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com