Electric heating device and distillation system for crude titanium tetrachloride containing high-concentration solid particles

A technology of crude titanium tetrachloride and electric heating device, which is applied in the direction of ohmic resistance heating parts, titanium halide, heating elements, etc., can solve the problems of reduced heat exchange efficiency, insufficient steam supply in the heating season, and large heat loss in sewage discharge. Achieve the effect of reducing sewage discharge, solving unstable production, and eliminating pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but not as a basis for any limitation of the invention.

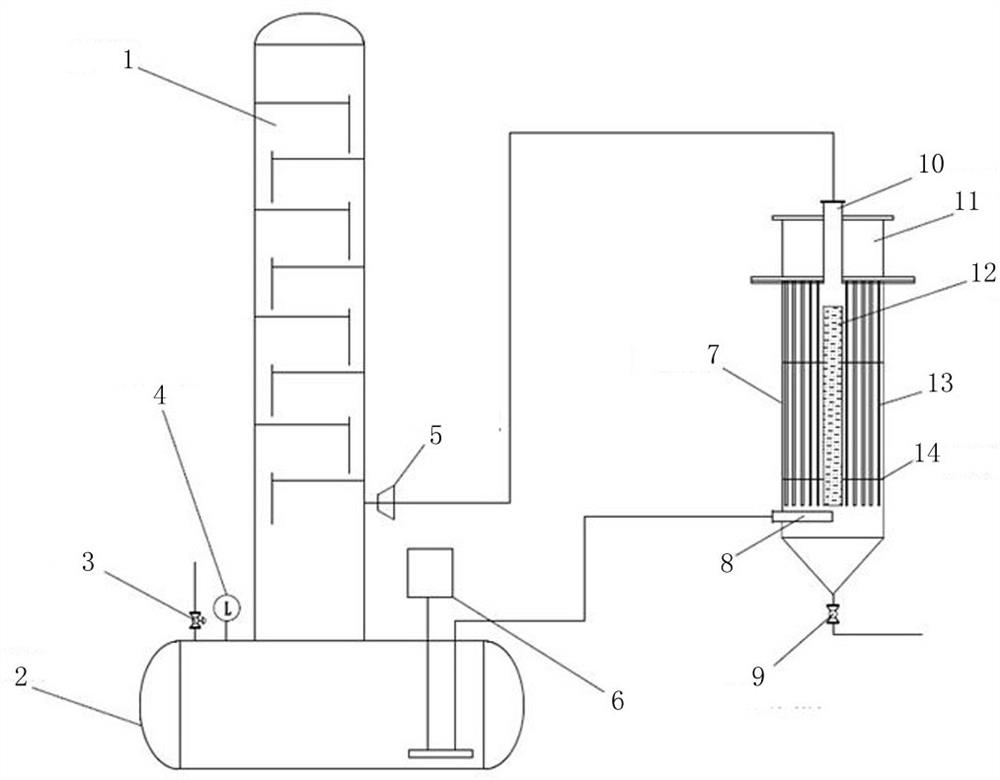

[0021] A distillation system for crude titanium tetrachloride containing high-concentration solid particles includes a high-boiling impurity separation system composed of a distillation column 1 and a distillation column still 2, and an electric heating device for crude titanium tetrachloride.

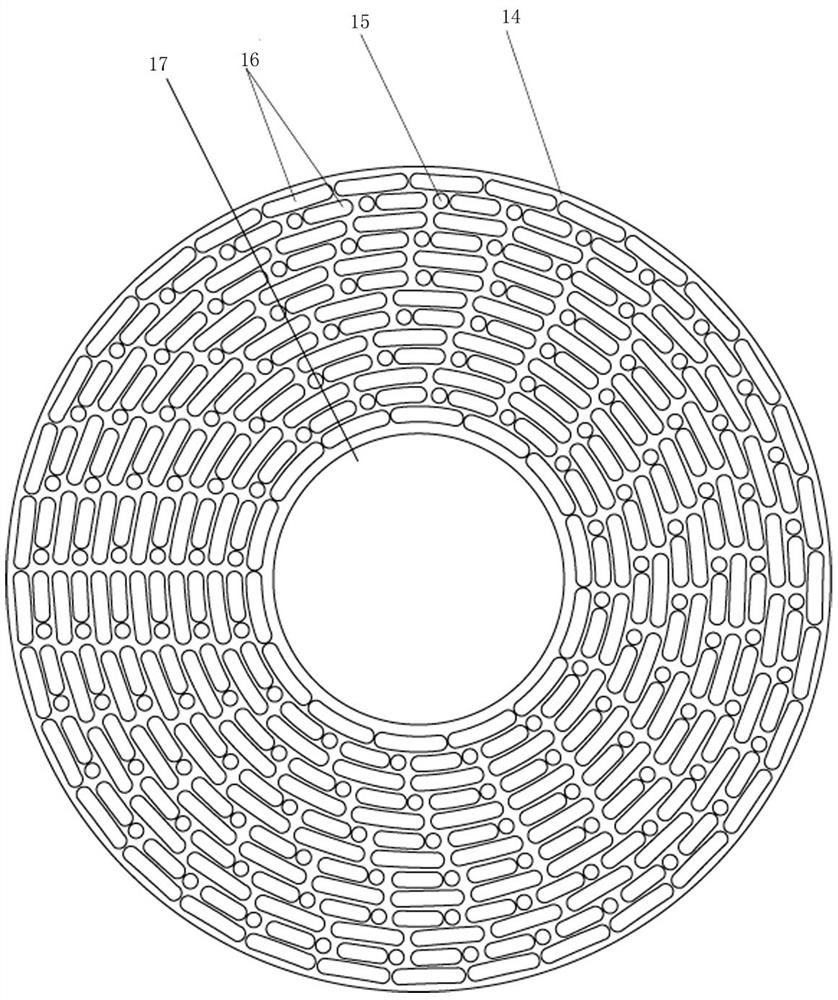

[0022] The described thick titanium tetrachloride electric heating device includes an electric heating kettle 7, a fixed mesh plate 14 and a plurality of electric heating rods 13. The electric heating kettle 7 is a cone-column composite cylinder structure, the upper part is a cylindrical cylinder body, and the lower part is a cylindrical cylinder body. Conical cylinder, the large diameter end of the conical cylinder is connected to the lower end of the cylindrical cylinder, the bottom end of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com