Liquid fermentation culture medium online degassing apparatus

A technology of liquid fermentation and degassing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

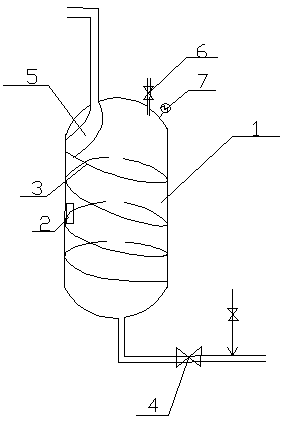

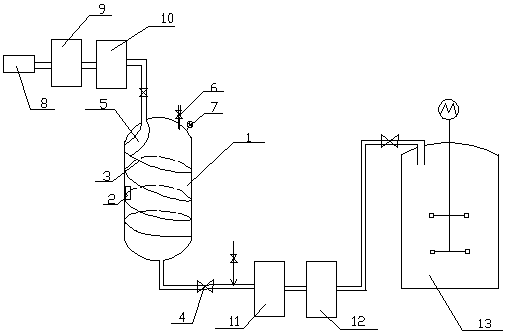

[0014] Such as figure 1 As shown, an online degassing device for a liquid fermentation medium includes a tank body 1, which is provided with a feed port and a discharge port; the middle part of the tank body 1 inner wall is provided with a liquid level sensor 2, and along the The inner wall of the tank is provided with a spiral deflector 3; the liquid level sensor 2 is connected to the electromagnetic valve 4 provided on the feed port; The end of the flow plate; the feed inlet is connected with a variable-diameter guide tube 5 with a diameter greater than that of the feed liquid port, and the material liquid flowing out of the variable-diameter guide tube flows along the deflector; the top of the tank is provided with a discharge tank Exhaust port 6 and pressure gauge 7 for internal gas.

[0015] The distance between the upper end of the deflector 3 and the mouth of the tank body 1 is 1 / 4 of the total length of the tank body 1, and the distance between the lower end of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com