Thin film in-line degasser

A degasser and appliance technology, applied in the direction of liquid degassing, rapid degassing, chemical instruments and methods, etc., can solve problems such as discarding, achieve easy cleaning, improve flexibility, and eliminate difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

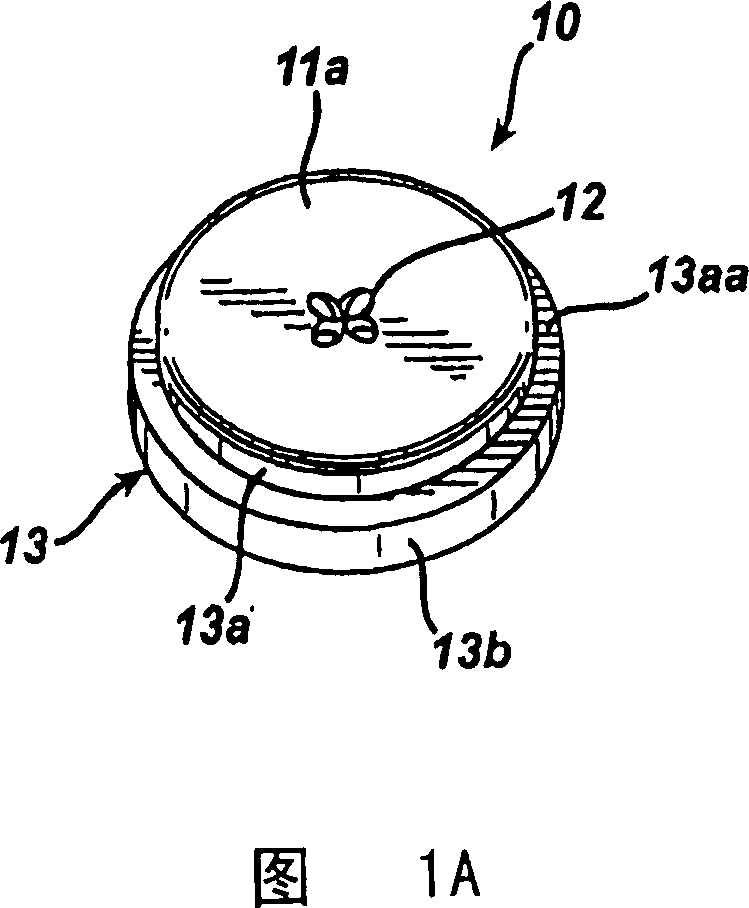

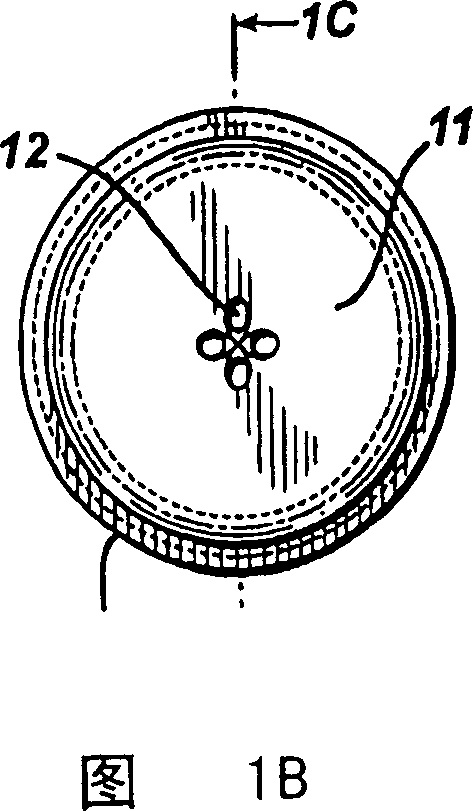

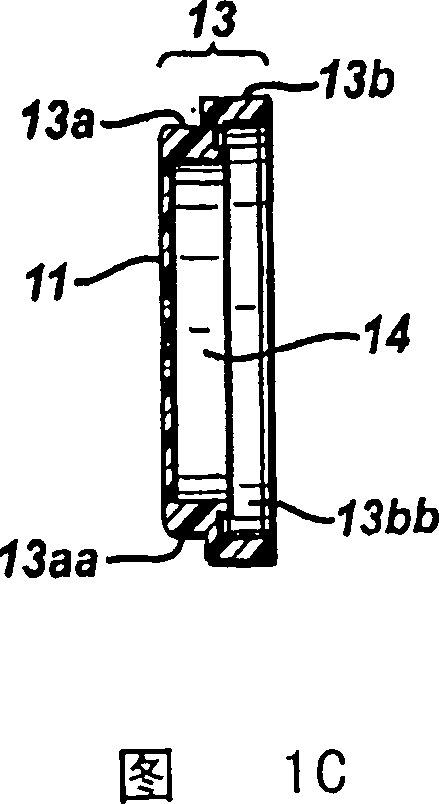

[0022] The invention has particular utility in degassing liquid monomers used in the manufacture of ophthalmic lenses. Examples of ophthalmic lenses in this regard include, but are not limited to, hard, soft, hard gas-permeable contact lenses and intraocular lenses and lenses for eyeglasses. The present invention has particular utility in soft contact lenses generally classified as hydrogel lenses; Liquid monomers prepared from acrylates, and acid esters are of particular utility. In this specification, the term "liquid monomer" includes the above-mentioned monomers and mixtures thereof, including any or all of the above-mentioned mixtures with other additives known in the art such as cross-linking agents and reinforcing agents. Gases that are generally dissolved in the liquid monomer and that are desired to be removed (outgassed) include oxygen and may include nitrogen and other gases. Soft lenses in this regard are typically prepared by free radical polymerization of a mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com