Ultra-low temperature steel in great heat input welding and manufacturing method of steel

A large heat input welding and manufacturing method technology, applied in the field of low-carbon low-alloy steel, can solve the problems of low-temperature toughness deterioration and low-temperature toughness in the heat-affected zone, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

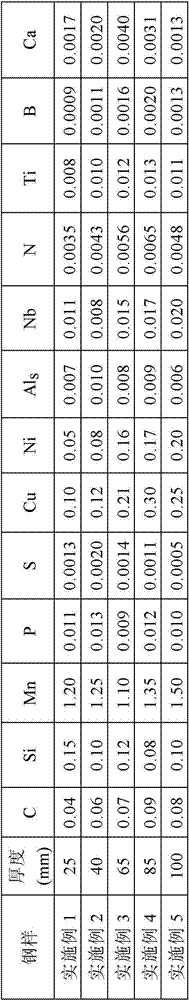

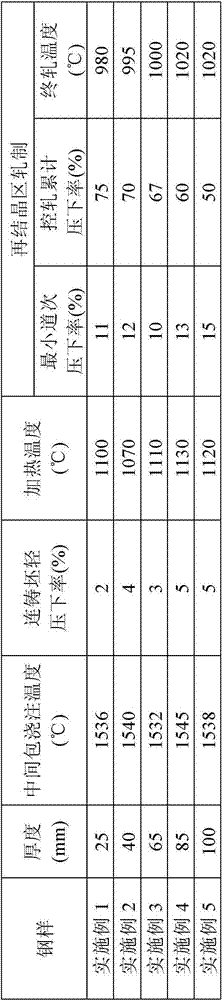

[0066] Refer to Table 1 for the composition of the steel in the embodiment of the present invention, Table 2 to Table 4 show the manufacturing process of the embodiment of the present invention, and Table 5 shows the properties of the steel in the embodiment of the present invention.

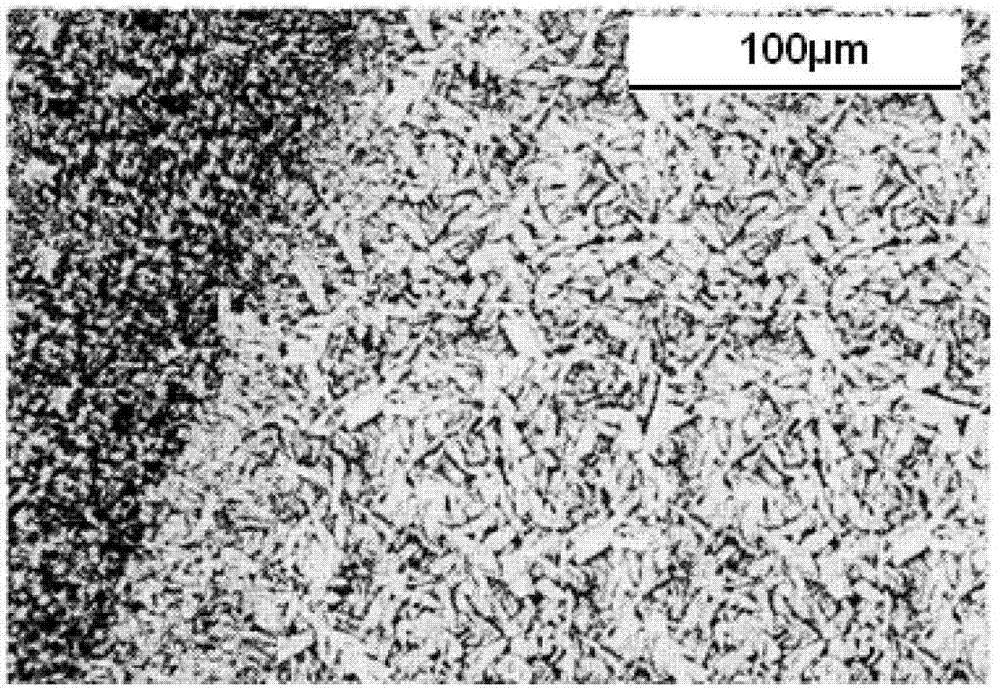

[0067] From Table 5 and figure 1 It can be seen that the microstructure of the ultra-low temperature steel obtained in the present invention is uniform and fine equiaxed ferrite + a small amount of dispersed bainite; its yield strength is ≥355MPa, tensile strength is ≥490MPa, and impact toughness at -60°C is ≥100J .

[0068] In summary, the present invention uses a simple combination design of alloying elements without the need to add Ni and Cu precious elements in large quantities, optimizes the TMCP manufacturing process, and obtains excellent low-temperature toughness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com