Method and apparatus for forming composite part from multi-layer pre-preg composite charge

A prepreg and filling technology, applied to household components, household appliances, and other household appliances, can solve the problems of increasing manufacturing cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

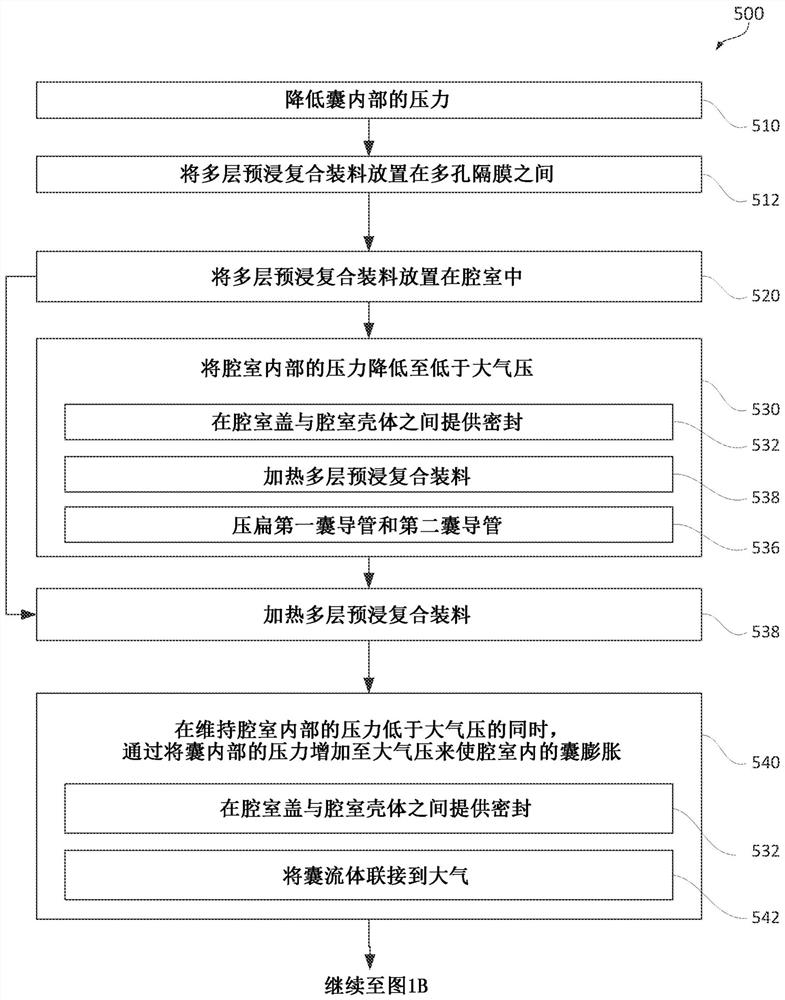

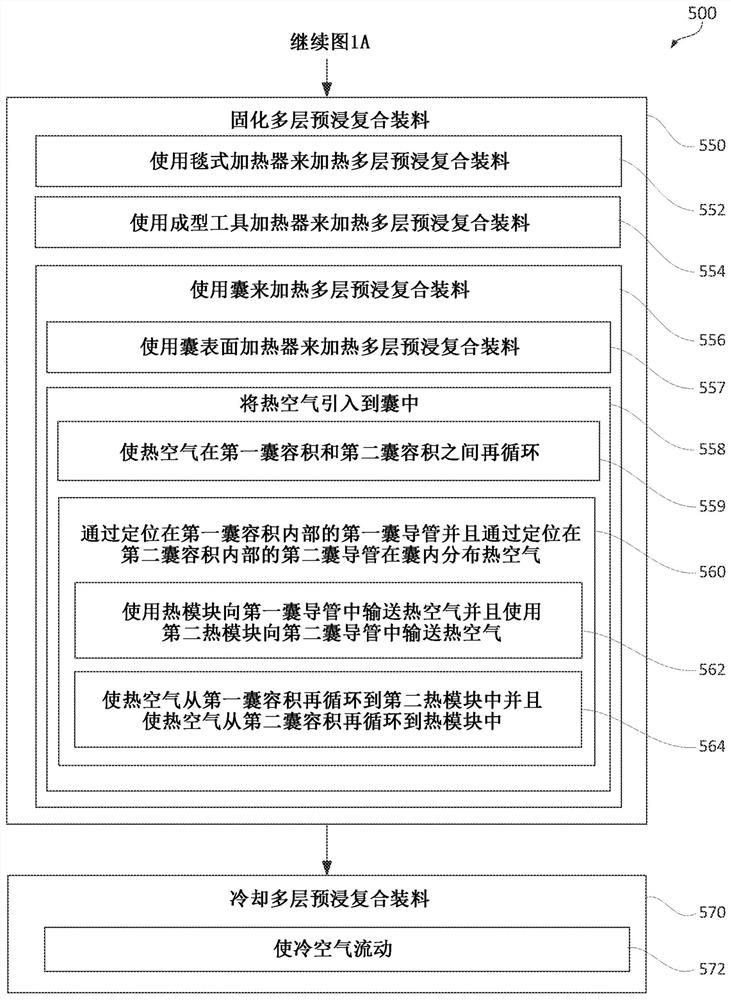

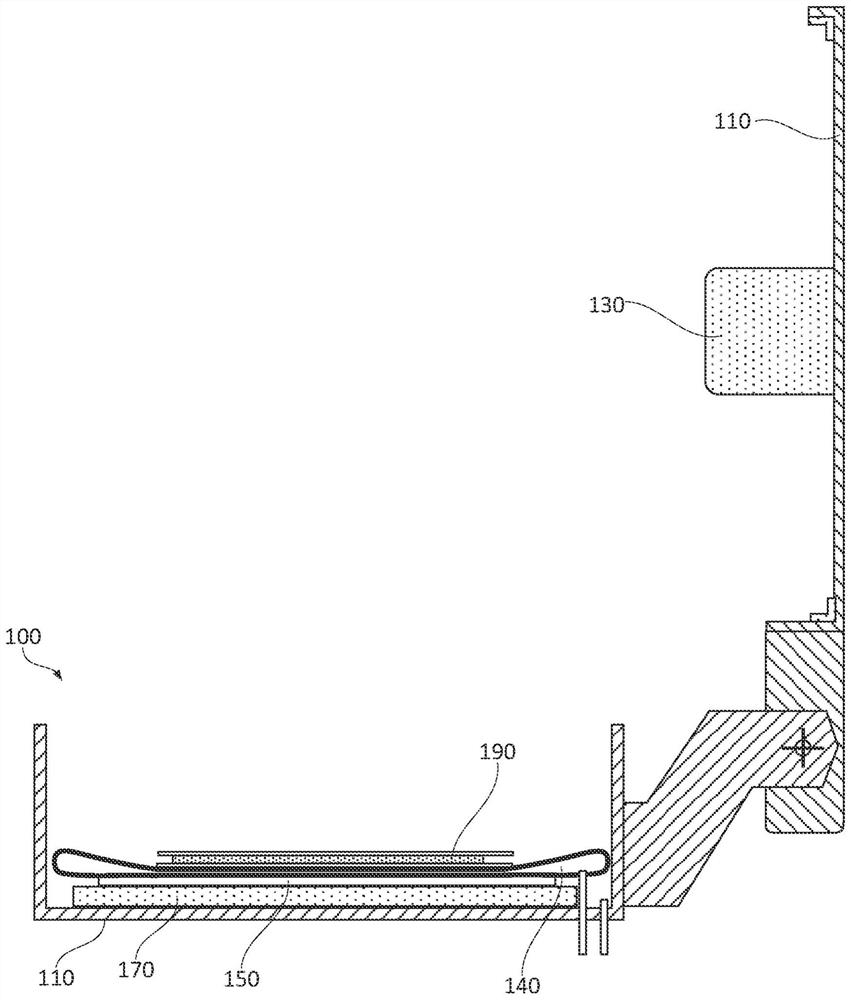

[0039] general reference Figure 1A with Figure 1B , especially for example Figure 3A to Figure 3B , for illustrative purposes only and not limitation, the following portion of this paragraph describes Example 2 of the subject matter disclosed herein. According to Example 2, which encompasses Example 1 above, during the step of reducing the pressure inside chamber 100 to below atmospheric pressure (block 510 ), multi-layer prepreg composite charge 190 is separated from forming tool 130 through gap 134 .

[0040] Gap 134 ensures that the portion of multilayer prepreg composite charge 190 facing forming tool 130 remains exposed and available for degassing (or more specifically, initial degassing prior to compressing multilayer prepreg composite charge 190 ). Once the forming tool 130 is in contact with the multi-layer prepreg composite charge 190 and the multi-layer prepreg composite charge 190 is compressed between the bladder 140 and the forming tool 130, the degassing path...

example 3

[0042] general reference Figure 1A with Figure 1B , especially for example figure 2 , Figure 3A with Figure 3B , for illustrative purposes only and not limitation, the following portion of this paragraph describes Example 3 of the subject matter disclosed herein. According to Example 3 covering Example 2 above, the chamber 100 includes a chamber case 110 and a chamber cover 120 coupled to the chamber case 110 and pivotable relative to the chamber case 110 . The step of reducing the pressure inside the chamber 100 to below atmospheric pressure (block 530) and reducing the pressure inside the chamber 100 by increasing the pressure inside the bladder 140 to atmospheric pressure while maintaining the pressure inside the chamber 100 below atmospheric pressure. The steps of inflating the bladder 140 (block 550 ) each include (block 532 ) providing a seal between the chamber cover 120 and the chamber housing 110 . The forming tool 130 is attached to and supported by the cham...

example 5

[0047] general reference Figure 1A with Figure 1B , especially for example Figure 3A with Figure 3B, for illustrative purposes only and not limitation, the following portion of this paragraph describes Example 5 of the subject matter disclosed herein. According to Example 5, which encompasses Example 4 above, heating the multi-layer prepreg composite charge 190 prior to inflating the bladder 140 within the chamber 100 (block 538) reduces the pressure inside the chamber 100 to below atmospheric pressure ( Block 530) is executed thereafter.

[0048] Heating the multi-layer prepreg composite charge 190 prior to inflating the bladder 140 within the chamber 100 facilitates degassing the multi-layer prepreg composite charge 190 . Such as Figure 3A with Figure 3B As shown, the forming tool 130 is not in contact with the multi-layer prepreg composite charge 190 at this stage, and the entire surface of the multi-layer prepreg composite charge 190 is exposed or covered by per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com