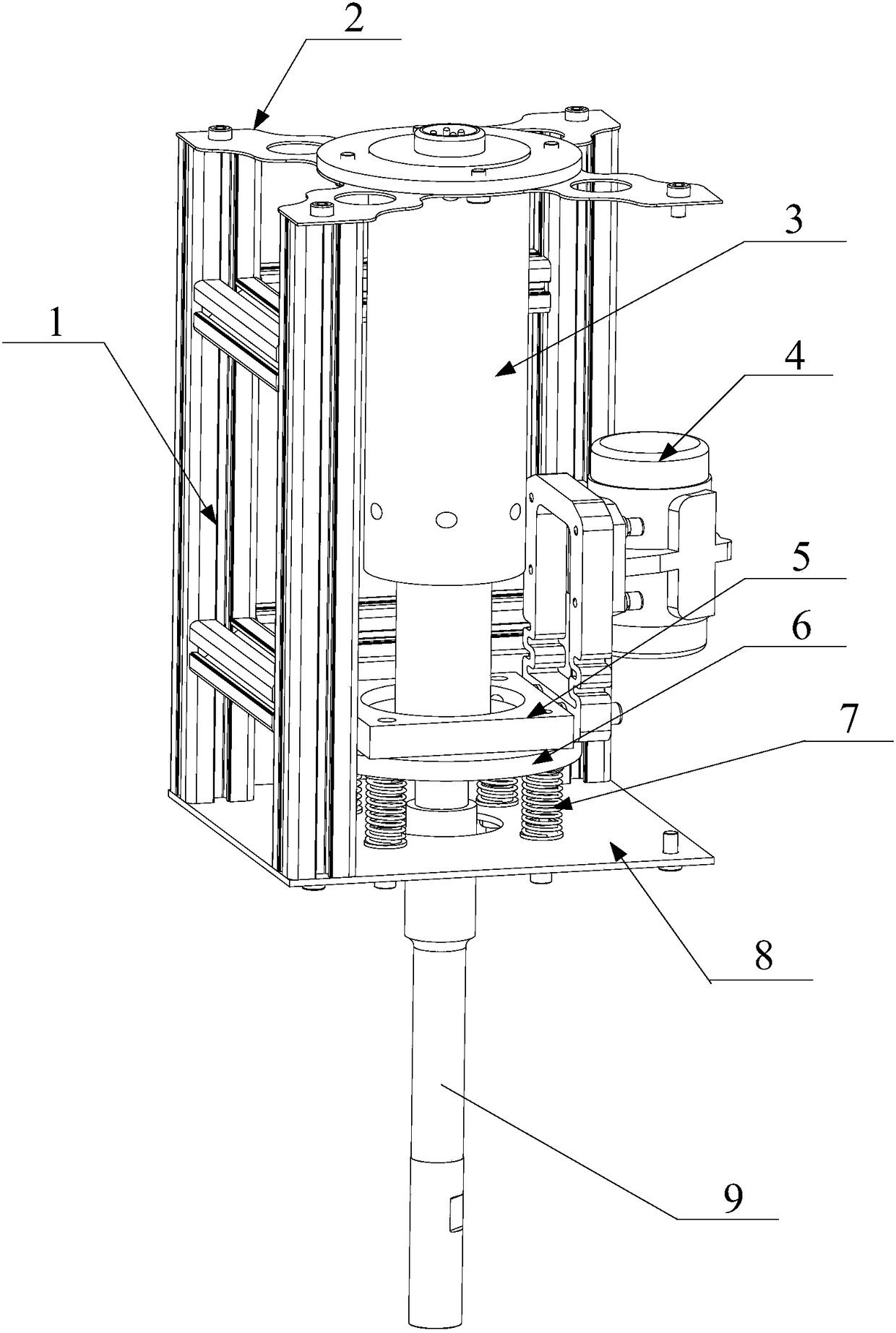

Ultrasonic Stirring Melting Device

An ultrasonic stirring and ultrasonic technology, applied in the field of metal smelting, can solve the problems of small volume and range of ultrasonic melt, and achieve the effect of avoiding standing wave and attenuation problems and increasing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

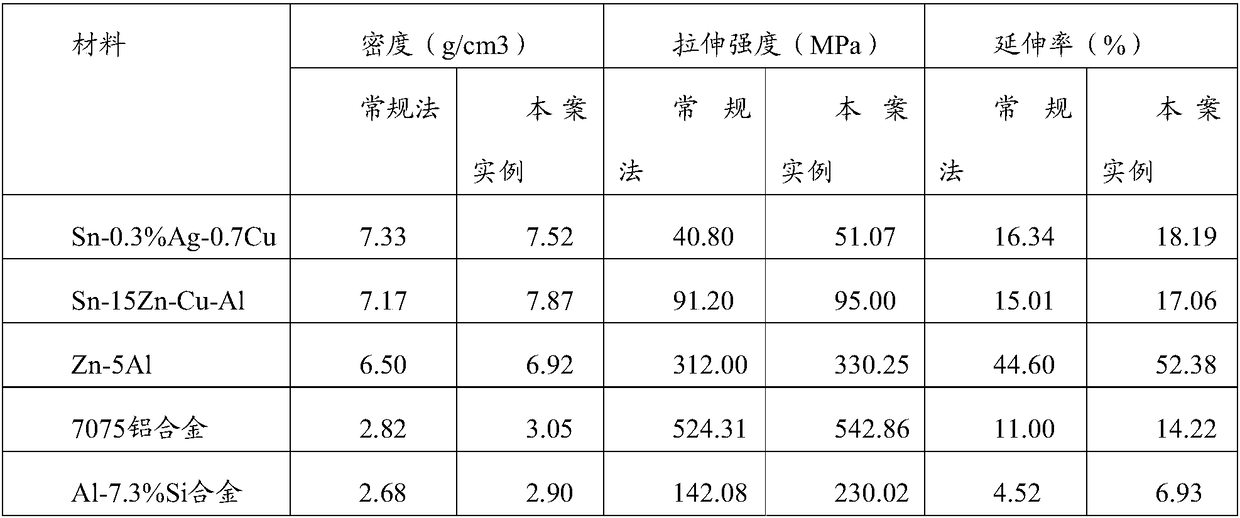

Examples

Embodiment 1

[0040] (1) Fully preheat the ultrasonic amplitude rod 9, and control the preheating temperature at 230°C. (2) Turn on the ultrasonic transducer 3 and the vibration motor 4, set the power of the ultrasonic transducer 3 to 500W, and the frequency is 15KHz, and the frequency of the vibration motor 4 is set to 15Hz, and the ultrasonic amplitude rod 9 emitting end faces are suspended on the Sn -0.3%Ag-0.7Cu alloy molten pool crystallizer, keep warm at 230°C and oscillate ultrasonically for 3min. (3) Turn off the ultrasonic transducer 3 and the vibrating motor 4, pour the molten metal into the mould, and obtain the Sn-0.3%Ag-0.7Cu alloy casting after air cooling.

Embodiment 2

[0042] (1) Fully preheat the ultrasonic amplitude rod 9, and control the preheating temperature at 220°C. (2) Turn on the ultrasonic transducer 3 and the vibration motor 4, set the power of the ultrasonic transducer 3 to 1200W, the frequency to 25Hz, the frequency of the vibration motor 4 to 50Hz, and suspend the emitting end of the ultrasonic amplitude rod 9 in a 220°C constant temperature Sn-15Zn-Cu-Al alloy molten pool crucible, ultrasonic vibration 3min. (3) Turn off the ultrasonic transducer 3 and the vibration motor 4, and water-cool to obtain a Sn-20Zn alloy casting.

Embodiment 3

[0044] (1) Fully preheat the ultrasonic amplitude rod 9, and control the preheating temperature at 400°C. (2) Turn on the ultrasonic transducer 3 and the vibration motor 4, set the power of the ultrasonic transducer 3 to 500W, the frequency to 30KHz, the frequency of the vibration motor 4 to 60Hz, and suspend the emitting end of the ultrasonic amplitude rod 9 in a 400°C constant temperature In the crucible of the Zn-5Al alloy molten pool, ultrasonically oscillate for 2 minutes. (3) Turn off the ultrasonic transducer 3 and the vibration motor 4, and water-cool to obtain a Zn-5Al alloy casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com