Oil-gas-washing-coupled oil-water initial separation method and device

A preliminary separation, oil-water technology, applied in the direction of mechanical dehydration/demulsification, petroleum industry, combustible gas purification, etc., can solve the problems of high material consumption, large floor space, low efficiency, etc. The effect of reducing land occupation and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

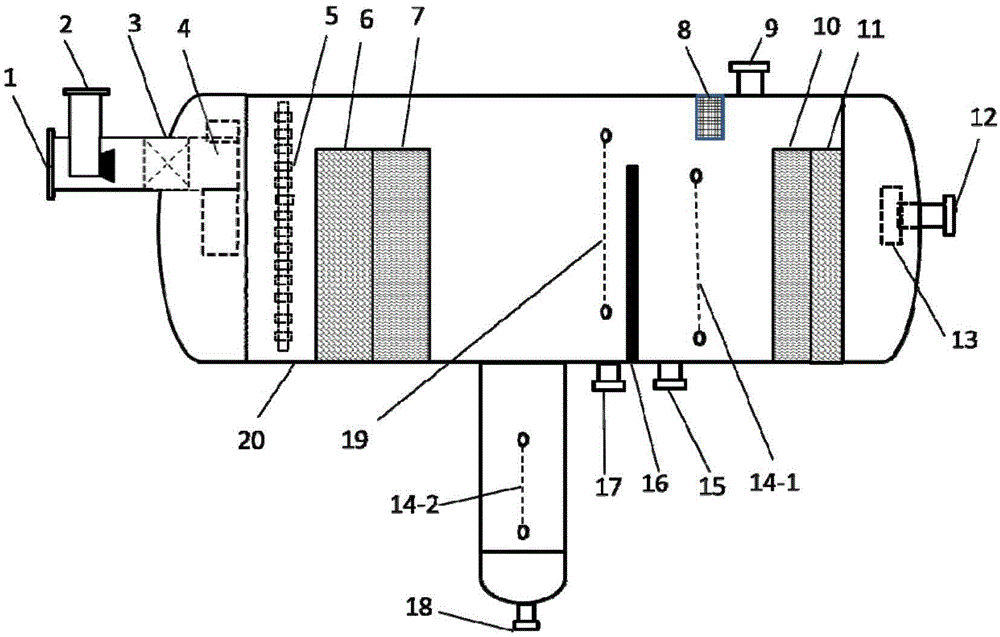

[0043] In view of the problems of Comparative Example 1, this embodiment improves its method and device. The improved process conditions are as follows:

[0044] (1) Process parameters: the oil dehydration process on the left side of the partition, the oil dehydration is designed according to the liquid flow rate of 0.02m / s, the average liquid level height is 50%, the residence time is 180s, and the water bag is designed according to the separated sewage interval of 0.5 hours; In the side oil dehydration process, the oil dehydration is designed according to the liquid flow rate of 0.025m / s, the average liquid level height of 40%, and the residence time of 120s.

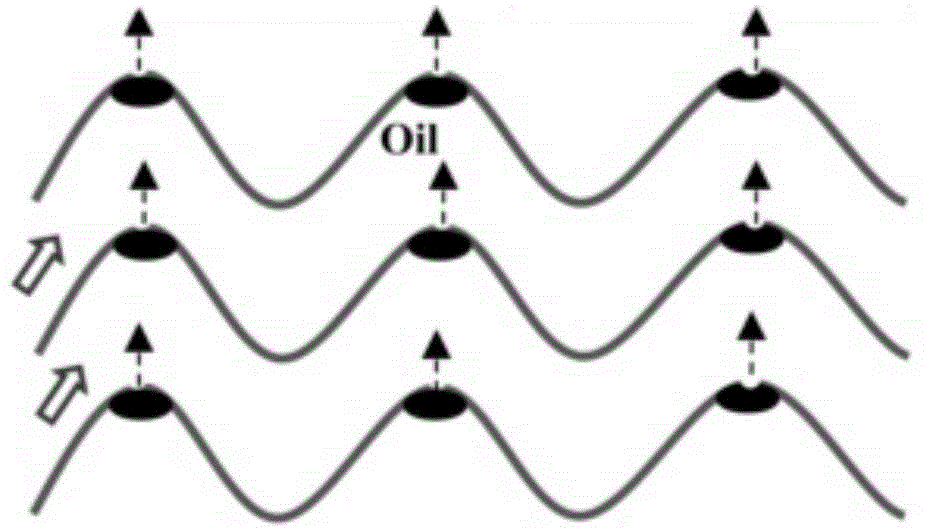

[0045] (2) Internal component form: the length of the tubular liquid-gas mixer is 2.2 times the diameter of the pipe, the inlet adopts a T-type liquid-gas separator, and the inlet flow rate is controlled at 4.2m / s, which meets the requirements of rapid gas washing and rapid separation of mixed liquid and gas requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com